Machining and marketing are two very different things. Perhaps they could not be more different.

For example, machining offers a predictable link between input and output. A particular job on a particular machine tool ought to have a reasonably predictable cycle time. Upgrade the tool or refine the tool path, and you might be able to shorten this time. Introduce a setup-reducing accessory such as an indexer, and the overall processing time can change dramatically. People who love machining love the rewards of this kind of process engineering.

Now compare that to marketing—or more specifically, marketing communication and promotion. Not only are these efforts unpredictable, but lack of predictability is the very reason why they matter. No one can say when a prospect’s mind is going to change. Some circumstance or pressure will provide the tipping point, compelling this person to give new attention to your type of product—in this case, CNC machining services. The aim of your promotional efforts is to be near the front of the prospect’s mind when this tipping point occurs because of the various positive impressions your business has made on this person over time.

How many positive impressions? No one can predict that, either. The difference between input and output is affected by any number of indeterminate factors, not the least of which is the attention and personality of each individual involved. This is why, from the perspective of a machine tool user, marketing looks like a mess.

But here’s the thing: You’ve got to do it. If you own or lead a machining business, and if you aim for its customer base to grow, then you need to connect somehow with future sources of work. In fact, marketing is important enough and nuanced enough that generally the owner or president of a manufacturing business needs to be involved in the effort. As a result, wherever you find a contract machining business that is serious about growth, you are also likely to find a business leader obliged to step outside the scope and comfort of his or her manufacturing-related experience.

Job shop owner Albert Raczynski is candid about his feelings on this. “I signed on to do machining,” he says. “I didn’t sign up to do marketing and sales.”

Yet he has done these things. Arguably, he has done them well, because his efforts have led to business. His shop, Machined Concepts, opened its doors in Elgin, Illinois 3 years ago. This year, he achieved what feels to him like critical mass, as he now has enough work to fill his capacity much of the time.

On a recent trip to Chicago, I met with two shop owners in that area to talk about their marketing efforts. The other shop I visited is considerably more established—Carr Machine & Tool of Elk Grove Village, Illinois.

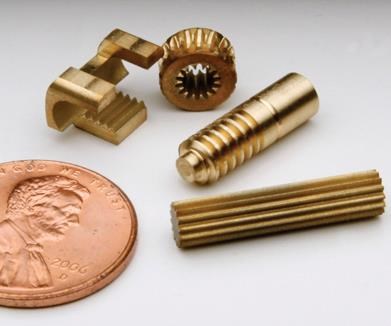

Jim Carr is the second-generation owner. He has increased the shop’s efforts to seek and win new business because he aims to see the company diversify into markets beyond the ones it routinely serves today. One of the more distinctive of those markets today is industrial printing equipment. In producing components for this sector, the shop has become proficient at machining parts that involve both (A) close tolerances and (B) machined features at various angles around the part’s volume. Mr. Carr thinks this competence for close-tolerance, multi-face work can serve various additional markets, including ones in which the shop is only slightly established today.

For either shop, the points described below do not make up a complete marketing or promotion formula. Rather, what follows are some elements of these companies’ formulas that seem to be working. As you read, consider whether any of these ingredients might make sense in your shop’s marketing formula as well.

The Consumer Experience

One of the more important and unusual ways that Carr Machine makes positive impressions on customers and prospects is by bringing aspects of the B-to-C (business-to-consumer) experience into the world of B to B (business to business).

Mr. Carr asks, “Why isn’t ordering a machined part more like ordering a book from Amazon?” He thinks the experience ought to be similar, and he sees value in giving the customer a comparable level of comfort and consistency.

One aspect of this is packaging. Every part is encased in foam and either sealed in plastic or wrapped in vapor-corrosion-inhibiting paper. He wants customers to expect these measures as routine. The shipping label is then branded with Carr’s logo, with the purchase order number on that label highlighted by hand. Thus the customer can see immediately that a Carr part has arrived on the dock, and can know the identity of that part without unpacking the box.

An even more vital aspect of the B-to-C experience is access to information. Like Amazon, Carr Machine automatically sends an email when each order ships, including order details and the UPS tracking number. A customer can also log onto a secure area of the shop’s website to view current information about in-process jobs for that particular account. “Someone waking up at 2 a.m. with a worry about a particular part shouldn’t have to wait until we start our day to get that worry resolved,” Mr. Carr says.

These efforts directly led to new business in at least one case. Because of the attention the shop gives to details such as these, a recent new customer says, “I genuinely feel that you get the quality issue, and that’s what we’re looking for.” The customer chose Carr over other shops that had quoted lower prices.

Facebook Advertising

Given this attention to a consumer-style experience, it’s perhaps fitting that Carr Machine has also found value in a consumer-oriented advertising vehicle: Facebook. Pay-per-click advertising on Facebook is inexpensive and can be targeted demographically. Carr targets its ads on Facebook only to people who have mechanical engineering degrees.

Soon after the shop began this advertising, the first Facebook-prompted request for quote (RFQ) came in. The prospect was an aircraft-industry supplier, and the RFQ arrived with a note expressing surprise. The contact wrote, “I guess this means Facebook advertising works.”

Success in this case amounted to only a new contact—the job itself was not a good fit. However, Mr. Carr says this response reinforced his belief that social media deserve his attention. He remains active in Facebook and Twitter, as well as in LinkedIn, which he is finding to be the most effective of these channels for making connections that are directly meaningful to his business.

Still, he says, the most meaningful connections are in person rather than online.

Networking

Mr. Carr has now made it a priority to routinely get out of his shop to meet other business leaders—a practice he wishes he had cultivated earlier. Any given in-person connection can lead to an introduction to someone else, and this is how the network grows. “I have done more networking in the past couple years than in 30 or more years prior,” he says.

Becoming active in the Illinois-based TMA (Tooling & Manufacturing Association) has been particularly worthwhile. Today, he sits on TMA’s board. Thanks to a TMA member, he was recently introduced to someone searching for the right machining supplier for a part about to be reshored. Without the introduction, Mr. Carr says he likely would never have met this person or learned about the project—even though the company in question is located only two blocks away from Carr Machine & Tool.

YouTube

At Machined Concepts, Albert Raczynski tries to see and capture the marketing potential of every part the shop runs. Any job might serve later as a useful illustration of what the shop is able to do. Therefore, if the job features some kind of distinctive challenge (even a slight one), and if the customer will allow it, then Mr. Raczynski videotapes that machining cycle for the shop’s YouTube page. He does this using a compact camera from GoPro mounted inside the machine’s workzone. At this writing, the shop has produced and uploaded 19 of these videos, showing a broad range of jobs on the company’s machining center and its live-tool lathe.

One example is a video of a turned part made from the plastic material Delrin. The part featured thin walls and a high L:D ratio for the ID machining. Viewers might notice those details, but the greatest challenge was something the video could not capture—the part’s tight lead time. Yet the video is useful even for portraying this challenge, because when a prospect questions the shop’s ability to rapidly engineer a machining cycle for an urgent part, Mr. Raczynski can talk about this very job and refer the prospect to this clip. In many ways, the YouTube repository is more descriptive of the shop’s capabilities than a collection of finished part photos could ever be.

Email Newsletter

Each new video is also potential content for the shop’s email newsletter. Roughly once per month (busy months are the exception), Mr. Raczynski prepares an HTML email that he sends to a prospect list, describing the shop’s recent work. He creates the newsletter from a template, and most editions include a link to new footage. The mailing list for this newsletter began with a list of email addresses obtained from the business development center of a nearby community college. Mr. Raczynski culled the list and added some addresses of his own, and he has continued to expand the list over time. The newsletter is simple enough not to take too much of his time and infrequent enough not to be a nuisance to recipients. This recurring encounter with prospects’ inboxes has provided a relatively unobtrusive way to remain in prospects’ minds.

Be Yourself

Part of the reason why those emails are not a nuisance—why they don’t come off as spam—is because they are authentic. Mr. Raczynski makes no attempt in these emails to close a deal (as if his prospects could be moved to a major purchase because of what a mass email says). Rather, his aim is just to share what the shop is doing.

“I think what we do here is cool,” he says, “so I feel like other people should think that, too.” And it is cool—largely because of the way the genuineness of this feeling comes across.

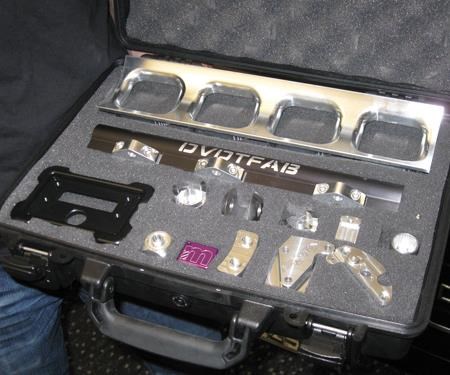

Another enthusiasm he shares is car racing. This interest provides a basis for friendship with people in the racing community, and machining work has come through these friendships. In fact, personal avenues of connection are particularly important for this shop because so many others have comparable equipment and capabilities. One larger job shop gives overflow work to Machined Concepts partly because the contact there is similar to Mr. Raczynski in age and style—the two of them relate. Being guarded or insincere about who you are closes the door to connections such as these.

Look Within

In addition to reaching outward, the search for new business should also involve a close look at who or what is already in the shop. This is a point that both shops make.

Machined Concepts’ relationship with one recurring customer began with a referral from a machine tool service technician. That technician had seen the shop from the inside, and he had seen various other area manufacturers the same way. Knowing the capabilities and cultures of many manufacturing businesses, he was able to provide a good match for a company that was looking for an outsource supplier.

At Carr Machine & Tool, Mr. Carr says today’s business is his shop’s best source of business in the future. He continually looks for ways to improve the manufacturing process for recurring jobs, and he encourages customers to rely on Carr Machine for this ongoing improvement. For example, Mr. Carr persuaded one customer to let the shop machine a plate cover component from solid steel instead of a casting, saving the customer considerable cost. Later, the shop was able to switch from ground stock to hot-rolled plate for this part, reducing the cost further.

Patience

Prospecting for new business can be a slow process, and it can lack the satisfaction of regular signs of progress. The discipline of marketing entails the patience of recognizing this. In the case of a machine shop, though, bringing in just one customer that is close to ideal could pay for the investment in these efforts.

For Mr. Carr, an aspect of this discipline is sometimes saying no. He wants to expand business by bringing in just those customers that Carr Machine is particularly well-equipped to serve. That means not getting distracted by opportunities that other shops might handle more effectively. Marketing for him will be a steady search.

“I can wait,” he says. “I know the right customer is out there.”

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)