Magnetic Holding Pattern

In finding a way to allow magnetic milling chucks to hold parts that typically aren’t secured by the "invisible" workholding method, this shop happened upon a means to repeatedly position parts in any of its machine tools.

Sometimes while solving one problem, a solution to another dilemma serendipitously appears. That was recently the case for Anderson Pattern, in Muskegon Heights, Michigan.

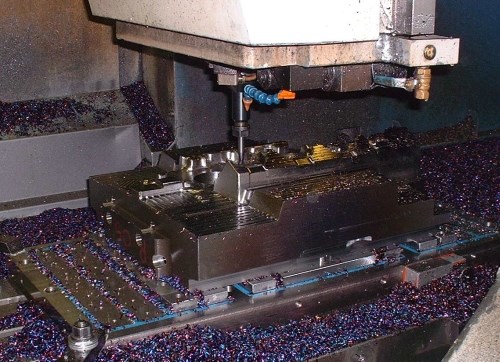

According to Mark Nielsen, machining manager, the more than 70-year-old pattern and moldmaking company began its journey to lean manufacturing 1 1/2 years ago. Since setup time reduction is central to any lean push, the company decided to switch from traditional mechanical workholding clamps to electropermanent magnetic milling chucks to hold billets and castings in its various vertical and horizontal machining centers. Its goals were similar to other shops that have integrated magnetic workholding—quicker change-overs, better repeatability and more spindle uptime thanks to access to up to five sides of a part in one setup.

Some of the company's large components fit the conventional profile of parts most commonly held by magnetic workholders—big billets with ample surface area for which the magnet can clamp to 12 tons per square foot. Others parts, including smaller billets and castings, did not provide enough surface area for the magnet to grip. Examples include wheel molds with 1-inch-wide annulus on their bottom surface or pattern blocks that have material removed from their backside for reduced weight.

Parts such as these are prone to twist on a magnet during cutting operations, especially when cutting forces are directed parallel to the face of the magnet (which occurs when milling about a part's periphery), versus down toward the magnet (as in a drilling operation). In fact, an axial cutting force only 1/18 of a magnet's total pulling force on a part can cause that part to twist out of position, according to John Powell, Ph.D., president of WEN Technology (Raleigh, North Carolina).

But where there is a will, there is a way. And in learning how to prevent small parts from twisting on magnets during cutting, the company happened upon a universal part positioning system for all of its machine tools and its two coordinate measuring machines (CMMs).

Invisible Workholding

Magnetic workholding chucks take advantage of commonly known magnetic principles. These magnets have north and south poles across which flux, or magnetic energy, flows. When a ferrous workpiece is located between magnetic poles, the flux enters the part and induces polarity in the part (opposite the magnet), causing an attraction between the part and magnet.

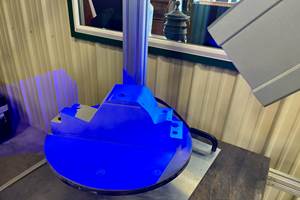

Electropermanent magnets are the magnetic workholding technology of choice for machine tools, and with good reason. These units use permanent magnets that are only energized after a quick shot of electricity is delivered by a remote controller that is temporarily connected to the magnet. The controller's cable is then disconnected, and the magnet will continue to hold the part until de-energized by another zap of electricity from the controller. Cable-free workholding is especially helpful on horizontal machines with pallet changing capability. Anderson Pattern uses a number of electropermanent magnets in both vertical machining centers (VMCs) and on tombstones used in horizontal machining centers (HMCs).

The key is to deliver the proper amount of magnetic flux that will hold the workpiece but not extend past the part's surface, which would magnetize the outside of the part. Chips would then stick to the part and be re-cut, reducing both tool life and surface finish quality. This is done through the use of pole extensions, which are cubes or strips of steel that may be screwed or placed on top of the magnet's individual poles to raise the workpiece off of the magnet. Pole extensions prevent damage to the magnet during workpiece machining, but also allow fine tuning of the amount of magnetic flux delivered into the part through the adjustment of the contact area between part and pole extension.

Pins Position, Prevent Sliding

Anderson Pattern's facility is divided into roughing and finishing areas. Billet blocks for patterns typically are first rough machined, then delivered to the finishing area, where four-axis contour milling is performed on the top of the block. After contouring, the blocks are returned to the roughing area for additional periphery machining work. When experimenting with its first workholding magnet, the company found that reference points which were added to the top of the block during finishing were off by up to 0.020 inch after re-installation on the roughing machine. This caused the tool to take a bigger than expected cut, yielding higher cutting forces that caused the blocks to twist out of position on the magnet.

Because the first process for each part was skimming the bottom of the blocks flat, Dr. Powell suggested moving the reference points from the top of the part to the bottom. The reference points, accurately machined holes to receive mating dowel pins, would be replicated on pole extensions screwed to the magnet's poles. The part could then be located on the pole extensions with dowel pins, which not only prevents parts from sliding, but also provides a way to repeatedly position a part in every machine tool and even the shop's two Brown and Sharpe CMMs.

Anderson Pattern makes its own pole extension rails by machining steel stock flat and square, then adding holes to allow them to be bolted to the magnet, as well as dowel positioning holes. Not all parts will receive dedicated dowel pin holes. In some cases, existing holes are reamed to a tight tolerance to accept pins.

Anderson Pattern doesn't use magnets for some finishing operations in which the cutting forces are directed downward. In these cases, steel rails with locating holes for dowel pins will be used to quickly position the blocks in the machine. The blocks are then secured to the machine's table with standard strap clamps.

Magnets are also used on tombstones used in a number of the shop's HMCs. Billets are first secured to the magnet and probed to determine their position. What would be the bottom surface of the block is then skimmed flat, and locating dowel pin holes are drilled. The part is then flipped over and located on the dowel pins holes for initial roughing operations.

Anderson Pattern plans to implement magnets on most of its machines. It has even developed an idea for a four-sided tombstone that would have magnets on the two wide faces and standard T-slots on other two faces for parts that require standard clamping methods.

Mr. Nielsen points out one other magnetic workholding benefit that is a key part of lean manufacturing—standardization. "Workers had their own way of clamping and setting up a part to be machined," says Mr. Nielsen. "Even if the parts were the same, each person would do it a little differently." The magnets deliver the same clamping force regardless of who energizes the magnet.

Related Content

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreMoving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)