Make Smart Factories Even Smarter with Metrology Data Management

Sponsored ContentBringing all of a plant’s quality data into a single digital system will reduce data entry errors, increase efficiency and improve overall product quality.

Share

By Mitutoyo America

Today’s factories are in the middle of a new manufacturing revolution: the rise of the Smart Factory. As modern techniques such as the Industrial Internet of Things (IIoT) and statistical process control (SPC) gain traction in the manufacturing space, exciting opportunities to improve efficiency and product quality are emerging every day.

A Smart Factory provides total insight into a myriad of activities across your plant, from the point of manufacture to final inspection. This exponentially empowers quality control and assurance, with every measurement of every component available for comparison and analysis. This increased visibility has profound implications for the future of quality control — and while achieving it isn’t always easy, the benefits are well worth the effort.

The potential benefits of a successful quality data management program are numerous, but three of them rise above the rest.

Reduced data entry errors. Increased efficiency. Improved product quality. All of these are possible through precise data management —and Mitutoyo makes it easy to upgrade to or incorporate the most advanced solutions into your process.

Improved Efficiency

A modern quality control process will save your team time and effort, without compromising the accuracy of their measurements. An effective data management solution is at the center of these efforts. Connected gages and major instruments that support electronic data collection — either via a USB port or a wireless connection — eliminate user error during the recording and data entry processes. This creates a more reliable database for your facility without requiring additional time or effort.

Mitutoyo's data collection and real-time SPC software unifies all measurement data from handheld and major instruments into a centralized database for analysis and reporting.

In fact, it may even require less. Because electronic data collection is easier for operators than manual recording, and because it cuts down on wasted time during inspection, the right data management system can cause exponential improvements in both speed and accuracy.

Integrated Data Management

Measurement data is one of the best indicators of how your manufacturing operations are proceeding, and whether your quality standards and industry regulations are being met. When this data is easily accessible in a single centralized database, your team can perform the advanced reporting and analysis that drive the Smart Factory — while fulfilling the strict requirements and standards of many industries.

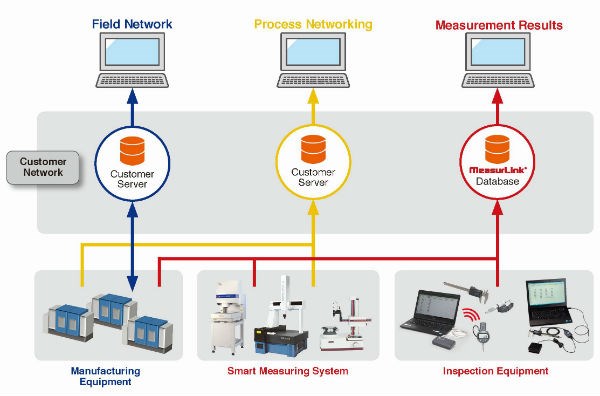

Your Smart Factory quality control solution can make centralizing data even simpler by leveraging your existing network. The best solutions gather data from across the plant: from manufacturing equipment, smart measuring systems and inspection equipment. Then, they route this data to a designated database on your network. This gives your team greater visibility as well as more opportunities to optimize performance.

Connecting all equipment to a centralized MeasurLink 9 database gives you a single source of truth for data management and analysis.

Easy Deployment

All data management software and and hardware are automatically compatible with your major instruments and SPC-enabled Mitutoyo equipment.

The most important attribute of a Smart Factory is that it should fit easily within your existing infrastructure. If your metrology instruments are SPC-enabled and your computer-controlled measurement equipment is network-connected, your investment in new equipment or software should be minimal. If new equipment is required, it should all be fully compatible and ready for use.

If your operations evolve as your facilities continue to grow, data management solutions can also adapt to those changes. The right data management solution includes modular hardware that can be repurposed for future applications, as well as scalable software that can support increased usage as required.

To make sure your data management solution is as easy to deploy as possible, choosing an effective data management partner is key. An initial consultation with data management experts will ensure that your solution is well-suited to your operations, your quality requirements, your plans for expansion and your budget.

Data Management Challenges in the Smart Factory

To achieve these benefits and successfully evolve your manufacturing facility, you need robust and reliable measurement data. However, obtaining that data isn’t always easy.

First, compatibility is a major hurdle for factories that require an end-to-end solution. If measurement instruments, connecting hardware and software do not all communicate seamlessly with one another, effective insight into machine performance will be difficult, if not impossible, to achieve. This is frequently an issue when manufacturers use data management solutions from multiple suppliers. Choosing a single reliable supplier is the easiest way to overcome this challenge.

An operator issuing a Caliper equipped with U-WAVE Fit to measure a sample for length, sending the data back to the PC where it is collected by MeasurLink Real-Time Standard.

Next, manufacturers with diverse product lines must make sure that their data management solution is flexible enough to meet their current and future needs. Selecting modular data management products that can work with multiple instruments and varied applications will help your data management solution grow as you do.

Finally, effectively implementing a data management solution can sometimes require a costly investment in new equipment. This expenditure can derail an already-tight budget, especially when the highest-quality equipment is required. Selecting a data management partner that can mitigate the cost of replacement gages will help manufacturers manage their budgets.

As a best-in-class producer of top-quality, SPC-enabled metrology held tools, computer-controlled equipment and software, Mitutoyo has everything you need to implement advanced, end-to-end data management and realize the full potential of the Smart Factory. To learn more about how our modular solutions and expert technicians can help you achieve an efficient, integrated, easy-to-use data management solution, visit www.mitutoyo.com/data-management-solutions.