Manufacturer Finds The Right Cam System

This manufacturer found that its new CAM system was difficult to use, and although they had invested time and money in training, their highly skilled programmer consistently outperformed the system using his own skills, a calculator, and a pad of paper.

Ten years ago Emtech, Inc. (Lino Lakes, Minnesota) purchased their first CAM (computer aided manufacturing) system. They soon found that the system was difficult to use, and although they had invested time and money in training, their highly skilled programmer consistently outperformed the system using his own skills, a calculator, and a pad of paper. Soon, the only thing they used the system for was to key their manual programs into the editor function and download them to the machines. Despite this unpleasant experience, Emtech realized that they needed the speed and flexibility of a CAM system in order to stay competitive.

Not anxious to make the same mistake twice, Emtech had a clear picture of what they wanted when they set out to purchase their next CAM system. According to Marv Peterson, President and General Manager, their goal was to be more responsive to customer needs by streamlining their front-end tasks: estimating jobs, process planning, and generating machine code.

They wanted a state-of-the art system that was easy to learn and use. This was important because they wanted to be able to distribute programming and process planning duties to several different CNC machinists for quick turnaround, instead of engineers and shop foremen taking responsibility for all programming functions. They wanted the system to be flexible enough to handle both vertical and horizontal milling, as well as turning. And, because they have a variety of equipment, they wanted to make sure that moving a job from one machine to another was quick and easy. Good support and training, they had learned, were vital factors. And, of course, a good economical value was also a key concern.

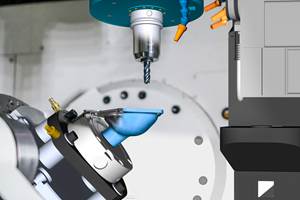

After a careful analysis of the various systems currently on the market, that involved benchmarking, demonstrations, and a close evaluation of technical features, Virtual Gibbs from Gibbs and Associates (Moorpark, California) was the system they selected. Virtual Gibbs is a two-, 2.5-, and simple three-axis CAM system designed for milling and turning applications.

Due to the fact that the system is easy to learn and use, Emtech has been able to train their machinists to be programmers. Having several machinists capable of using the system has sped up the manufacturing process and has given the shop maximum flexibility in job scheduling.

Steve Farris, NC programmer, says, "Generating geometry and the shape of tool paths is just a snap in Virtual Gibbs. It's very easy to use and requires a minimal amount of training. In just a few hours someone can understand the basics of what to do in the system, and in a couple of days they can be performing tasks that it used to take an experienced programmer to do."

The ability to debug part programs, visually, at the computer, has resulted in reduced time and waste at the machine, as well as easily optimized part programs. Now, mistakes are usually found in the engineering phase, rather than at the machine. Mr. Farris found that the graphics of their previous system, made it difficult to visualize what was happening to the part. With the rendering built into Virtual Gibbs, he is able to see the pre-machined blank as a solid model on the computer screen, and watch as the part is machined.

Making changes to part programs, whether it be to fix a mistake, adjust the tooling, or respond to an engineering change, is something with which all programmers are familiar. While Emtech does not encounter many engineering changes during a build cycle, revisions to the part are very common upon reorder. This is where Virtual Gibbs' "modeless" interface really shines. All data (geometry, tooling and tool paths) can be changed in exactly the same manner in which it was originally created. Once the new information is entered, it is simply a matter of pushing a button to "reprocess" the data, and new tool paths are immediately calculated. Steve Farris gives this example to illustrate the point:

A programmer at Emtech was creating a part program in which he attempted to machine the entire part and then go back and drill all the holes. When he viewed the image of the rendered part in Virtual Gibbs, he could clearly see that some of the drilled holes rubbed up against the inside edge of the part. He immediately realized that he needed to drill the holes in those areas before it was milled out. To make the change, all he needed to do was to change the order of operations. Because of the graphic interface, this was accomplished by "dragging" an object (called a `tile') from its existing location on the process list to the desired position. A single button push recalculated all the affected tool paths. The error was fixed in under two minutes. According to Mr. Farris, it would have been very difficult to see the error in advance, if they had not viewed the rendered image of the part. They would have found the problem at the machine, where it would have been much more time consuming and expensive to fix.

Cut part rendering has been useful in several other areas of the business as well. Emtech contends that a growing trend among their customer base is the ability to view prototypes and short run production with reduced lead times. Emtech has been able to use the rendering feature of Virtual Gibbs to accomplish these goals. They are able to program the part according to the customer's specifications, and instead of building an actual prototype, they can simply show the customer the rendered image of the part. In this way, Emtech can make suggestions on ways to save the customer money, without actually machining the part. The customer can make changes to the design or manufacturing process, and those changes can be implemented quickly. The rendering capability in Virtual Gibbs saves both Emtech and their customers valuable time and money, which makes them both happy.

Through attention to all areas of their business, Emtech has positioned themselves to be in the top ten percent of precision shops in the Minneapolis/St. Paul area, based on overall technology, capability and service to their customers. According to Marv Peterson, CAM is an important part of that equation. By employing a powerful and productive CAM system that was easy to learn and use, they have increased productivity and throughput and as a result, reduced costs. More importantly, Emtech has become more responsive to customer needs, which helps give them a definite edge over the competition.

Related Content

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreWhen to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

Read MoreLarge-Format Machining With Small Cutting Tools and Dynamic Motion

Napoleon Machine, a defense contractor that provides parts for the M1 Abrams tank, recently took advantage of a CAM feature that allowed the company to streamline its cutting strategies and program offline. Here’s how the shop cut cycle times nearly in half with its large-format five-axis machining operations.

Read MoreImprove Machining Efficiency Through Digital Twin Simulation

Full simulation of a machining cycle using digital twins can not only identify crashes before they happen, but provide insights that enable the user to reduce cycle times.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)