Measuring And Inspection System Slashes Machine Time

This shop bought an inspection system to complement its five-axis wire EDM.

With a shop full of CNC grinding machines, machining centers and Vollmer saw-sharpening machines, Riverside Tool in Elkhart, Indiana constantly strives to efficiently manufacture high-quality cutting tools.

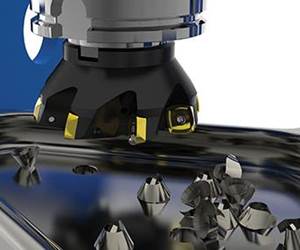

Founded in 1989, Riverside produces carbide and polycrystalline diamond (PCD) tools to shape wood, plastics and composites, including surface material and exotic species of wood. The company brazes the PCD tips onto cutterheads, router bits and saw blades. Riverside also services a range of cutting tools and produces insert tooling in the form of cutterheads, router bits and tools for custom applications. It sells these products to distributors and end-users nationwide.

To shape PCD tools, the company employs a Vollmer QWD 750H, an automatic wire EDM capable of machining tool edges in five axes simultaneously. Shortly after Riverside selected this machine, the staff on the shop floor suggested that the company acquire a smarTcheck tool measuring and inspection machine from Zoller Inc. By inspecting and measuring tools on the Zoller machine rather than the Vollmer, the company can free up costly machining time for CNC tool shaping rather than tool checking and setups. The objective was to maximize the productivity of the Vollmer.

According to the company, cost savings from reduced machine time on the Vollmer were immediately apparent. Following the installation of the new machine, the total production time was reduced by more than 50 percent because the need to create CAD drawings was eliminated. In addition, profile information could be directly transferred to the Vollmer machine.

The smarTcheck features the Saturn 1 vision system, which uses a 90-degree incident light camera with a swiveling optic carrier to measure in radial and axial directions. It checks parameters such as rake angle, helical pitch, land width and other characteristics. Cutting edges are displayed in transmitted light, permitting measurement of the tool contour parameters. The system also includes software to measure tool characteristics such as radius, contour cutting angle, clearance angle, chamfer width, concentricity and so on. Capable of close-up tool inspection, the camera helps the company discern chips or damage and measure precisely how much material to remove to restore the tool edge.

“This system allows us to fully inspect the tools we make—PCD tools and insert tools,” says Ron Migedt, Riverside’s owner. “This is important because the cutting edge imparts a surface to the material, and those edges need to be smooth.”

“In our industry, all tools are designed with hook and some with shear,” he continues. “So, what you see on the tool edge is not what you may see on the wood. Years ago, the only way to be certain of what you were going to get on the wood was to run a wood sample. Even though many shops today have a shaper setup to test-cut parts, this method is not a safe or accurate way for us to inspect our tools. Simply put, our employees are not woodworkers, so they are not prepared to set up the various tools.”

On the other hand, the new system affords the company the capability to effectively test-cut every tool via the camera system and duplicate what the user would see on the wood. Riverside can then determine the accuracy of the tool by extracting the resulting DXF file and comparing it to the company’s drawing file.

“Prior to shipping the tools to our customers, we preset all of the tools, adding or adjusting shims if necessary,” Mr. Migedt. “If we do that and there is minimal machine runout at the end-user, then the tools run perfectly every time.”

The inspection machine’s lasso function enables Riverside to measure thousands of points on a tool within seconds and compare actual or nominal dimensions using the DXF interface without writing programs. Data can either be printed in a test log or saved for reference and quality assurance.

The Zoller machine has also provided Riverside with a high degree of assurance that its tools are up to par before it ships them. Because the company is able to inspect the tools for damage, it can produce a correct tool, save material and reduce total production time by as much as 50 percent.

“We are positive that the tools are within tolerance and runout,” Mr. Migedt explains. “That even includes our insert spiral molder heads and other surfacing heads. We can be certain that each insert in a head is operating in the correct cutting plane, and that it is in balance. Otherwise, the end-user would see lines in the material, which is unacceptable.”

“We can inspect the entire cutting plane as the tool rotates in the machine’s precision spindle,” he continues. “Being able to check for misalignments and so on means that we can guarantee that our tools will operate line-free in a qualified machine.”

Riverside also uses the measuring and inspection machine to document the condition of incoming tools. The company may snap a picture and share recommendations with the customer. If the tool needs to be reset, then the operator can pinpoint precisely how much of the tip needs to be moved or replaced in brazing. After brazing, tools go back to the smarTcheck for setup on the toolholder so that operators can enter all measurements and parameters for the Vollmer machine. The tool and the holder are chucked in the Vollmer. The tool edges are machined, and the tool is returned to the Zoller for confirmation. The company also uses the Zoller to generate a list of the new tool measurements so the end-user can input them into a CNC router or other cutting machine.

“The data we can collect and store helps the customer understand what we do to the tools as well as what they need to know to adjust their machines correctly,” Mr. Migedt concludes. “It behooves the customer to know what type of technology you are using to make and inspect their tools. That goes for the insert side or our business, too, as the complexities that people are asking for have increased.”

Related Content

Twin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreNew Machining Technology Works With Old to Restore WWII Submarine

A set of donated boring bars that can be used in a 1954 boring head will enable volunteer machinists to recreate a pair of binoculars for the USS Pampanito.

Read More10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)