Moldmaker Doubles Feed Rates And Improves Finishes With NC Filtering Software

At Tredegar Molded Products (St. Petersburg, Florida), Ron Kalevich and David Lundy were looking for a way to increase feed rates and reduce polishing times for the injection molds they produce. Tredegar is a manufacturer of high precision, multi-cavity injection molds for the packaging industry.

At Tredegar Molded Products (St. Petersburg, Florida), Ron Kalevich and David Lundy were looking for a way to increase feed rates and reduce polishing times for the injection molds they produce. Tredegar is a manufacturer of high precision, multi-cavity injection molds for the packaging industry.

Mr. Lundy found that their machine tools were cutting below normal feed rates due to data starvation at the controls. This was occurring when the G1 linear moves generated by their CAM system were so close together that the control could not process the next move before the current move was completed. The machine would pause at each point, waiting for the control to catch up. With hundreds of thousands of points needed to define a molded cavity, this problem doubled the projected cutting time for their molds.

Another problem caused by the linear move approximation of their surfaces was poor surface finish. A machined mold could take up to 200 hours to polish to customer specifications. If the complex surfaces could be cut using arc motions instead of small linear motions, the finish would be significantly better right off the machine.

One possible solution Tredegar considered would be to customize their controls with high speed readers, but the cost was over $10,000 per control, and it would not address the finish problem. Another possible solution would be to purchase a new CAM system which would output arc moves for surface machining, which would eliminate the data starvation and greatly improve the surface finish. A new CAM system that could do this would cost over $20,000.

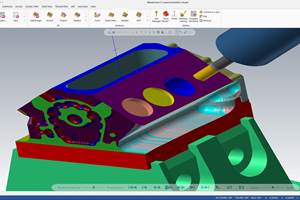

Mr. Kalevich came across a third and less costly solution to the problem; a less expensive software package which could convert his existing surface programs from linear moves into arc moves. The package, FilterMAX NC code optimizer from Machine Shop Solutions in Bald Cynwyd, Pennsylvania, converts the small linear moves of an NC surface program into tangent G2/G3 arc moves by fitting arcs through the existing data points in the NC file.

The arc moves generated by FilterMAX more accurately approximate surfaces, with chordal deviation and tangency tolerances controlled by the user. Tredegar typically holds tolerances of 0.0005 on their molds with the FilterMAX optimized programs, and their NC files are reduced up to 99 percent, as the thousands of linear moves are replaced by a smaller number of arcs.

In order for most CNC's to use arc motion, the arcs must lie in one of the three principal planes (XY, XZ, YZ). Tredegar's practice of utilizing constant Z-level and raster (XZ, YZ) machining made tangent arc tool paths a logical next step.

A cost study performed by Tredegar showed that implementing FilterMAX has saved a significant amount of money and benefited them in several ways: machining speeds are doubled, saving hundreds of hours of machining time per year; polishing times are cut in half, saving up to 100 hours per mold set; smaller NC files are easier to manage; machines operates smoother using arc motions, with less wear and tear on machine; tool life increased by over 30 percent due to smoother cutting and constant feed rates.

Mr. Lundy says, "We are very pleased with it. The software paid for itself on the very first job." MMS

Related Content

How Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

Read MoreFearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

Read MoreCAD/CAM System Requirements: An Overview

CAD/CAM programs are among the most demanding kinds of computer software. Smooth operation requires careful consideration of computer specifications.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More