More Effective Groove Milling For Gearboxes

A cutting tools supplier developed a grooving tool with an 18-inch gage length and a radial runout of just 0.004 inch. That tool enabled a gearbox manufacturer to increase its groove milling feed rate tenfold for a hard-to-reach bore.

Manufacturers that produce standard product lines have an advantage over contract shops in that they can continually upgrade their processes based on predictable machining needs. That’s what SEW Eurodrive’s Melvin Story does on an ongoing basis.

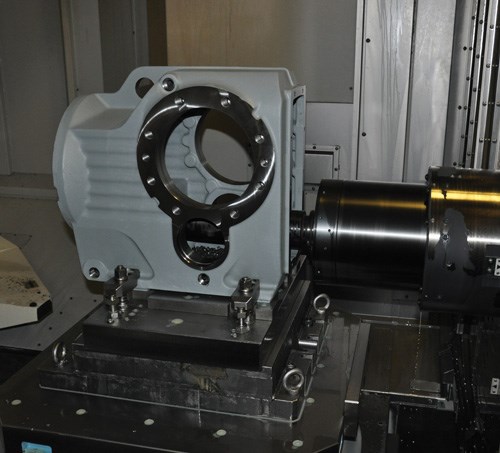

Mr. Story is an engineering technician for the Lyman, South Carolina supplier of right-angle gearboxes for power transmission and motion control applications. This U.S. headquarters of Germany-based SEW Eurodrive is where machining and assembly of housings and gear sets are performed in a 250,000 square-foot facility for various product models.

The predictability of having a standard product line doesn’t diminish the machining challenges that some of these gearbox components present, however. Housing castings, for example, require facing, boring and drilling operations often held to micron-level tolerances to ensure long unit life and high performance. Precision groove milling is also necessary to create snap ring grooves in two machined bores of differing sizes found in every casting. For the most part, groove milling the bigger of these bores is straightforward. The bore passes through a casting wall and can be easily accessed with a relatively short tool. Short tools, being inherently more rigid than long ones, allow more aggressive cutting to minimize cycle times. As Mr. Story points out (quite literally in the photo on the right), the smaller internal bore is more difficult to create, largely because it’s harder to reach.

That blind bore is located in the back wall of the casting and can be accessed only through an opening in the opposite end. A groove milling tool must be long enough to not only reach into the casting, but also to clear the fixture. The largest casting, which weighs approximately 300 pounds, requires a tool that is at least 18 inches long for this operation.

The tools that SEW Eurodrive previously used for the internal bore grooves on the large castings inhibited the production capability of the Makino a99e 50-taper HMCs that machine many of those castings. Slower interpolating feed rates were necessary to ensure groove accuracy because the tools lacked rigidity. The tools tended to flex at high feeds, so feed rates were restricted to 20 mm/min to produce the 120 mm-diameter grooves in the 110 mm internal bores.

Those tools also created extended stretches of spindle downtime while inserts were indexed. Mr. Story found that it wasn’t possible to accurately index the tool’s inserts at the machine. This wasn’t a machine operator’s fault. The tools simply had too much variability, so tool room attendants such as Wayne Ballenger indexed the inserts and measured them on a presetter to ensure proper insert positioning.

Based on past successes with small grooving and boring operations using Horn tools, Mr. Story decided that Horn would likely be able to provide a groove milling solution for the big castings. Although Horn is often associated with small-scale work, the company has developed a number of tools for large boring and grooving operations over the years.

Starting Small

Mr. Ballenger introduced Mr. Story to Horn cutting tools years ago. They first applied the tools to small grooving applications, tapping help from Horn representative Brian Hogg and Johnny Golden, sales person for Colony Tool.

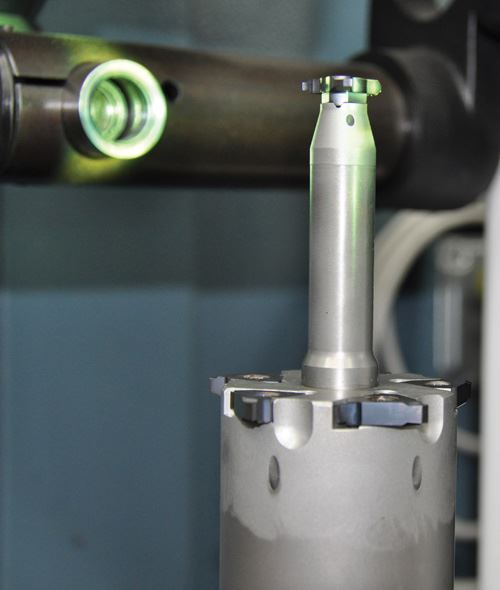

Most of those early applications used the Horn Mini Milling series of grooving and chamfering tools with diameters smaller than 1 inch. Small combination tools, such as the one shown on the previous page, were also used to allow one grooving tool to machine two bore sizes, eliminating a tool change and reducing overall cycle times. Each application was examined carefully so that the tool diameters and number of cutting edges were optimized for the operation to minimize cycle time and tool wear.

The tool Horn developed for the large casting provided benefits similar to those achieved with the smaller-diameter tools. Despite having a diameter of 3.5 inches and long gage length of 18 inches, radial runout of the 3-insert tool was measured to be just 0.004 inch. That, combined with the tool’s better rigidity, allowed a feed rate increase from 20 mm/min to 200 mm/min. This reduced the cycle time from 4 minutes to 1 minute. Mr. Story notes that tool life has been much longer, too.

In addition, Mr. Story has the confidence to allow operators to perform insert indexing at the machine without subsequent measurements on the presetter. Such repeatability, he says, is what he primarily looks for in cutting tools for a production environment.

Horn tools are being used to machine the grooves in the bigger bore of each casting, too. Those shorter tools have a relatively large diameter that allows 10 inserts to be used. The previous tools had a smaller diameter and just three inserts. Those ran at an interpolating feed rate of 190 mm/min. The Horn tool allows the Makinos to run at 888 mm/min when milling those grooves.

Establishing Relationships

Mr. Story says he will entertain offers from various cutting tool companies that manufacture milling and drilling tools. However, that’s not the case for grooving tools. He says he’s sticking with Horn for those applications. The quality of its tools, he believes, is punctuated by the assistance he’s received over the years from Mr. Hogg and Mr. Golden. The tight relationship and trust he has with his tooling representative and distributor have helped SEW Eurodrive integrate new cutting tool approaches faster, which allows the company to realize the benefits of improved efficiencies quicker, he says.

Related Content

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)