Mower Manufacturer Finds Staying In First Place Requires First-Class Technology

The Toro Company is a market-driven company with the objective to understand and translate customer requirements into cost effective product solutions. In addition to offering an extensive variety of lawn mowers, the company is in the snow removal market, electric outdoor appliances as well as irrigation equipment.

The Toro Company is a market-driven company with the objective to understand and translate customer requirements into cost effective product solutions. In addition to offering an extensive variety of lawn mowers, the company is in the snow removal market, electric outdoor appliances as well as irrigation equipment. In its components manufacturing facility located in Shakopee, Minnesota, special emphasis is placed on using state-of-the-art equipment and processes in metalworking. Consisting of three distinct manufacturing operations, the machining segment occupies about one third of the 146,000-square-foot building. There are 3500 active parts numbers involving 7500 operations that require 10,000 setups per year.

One of the major requirements in the manufacturing operations is to avoid unnecessary duplication of engineering drawings. Therefore, when the company selected NC programming software for its machining operations, it was necessary that the software interface with the company's Computervision CAD software. Furthermore, the program had to have both milling and turning capabilities. The software selected was Pathtrace's PAMS, (Pathtrace Inc., Walnut, California), a suite of software for the part programming of CNC machine tools.

The machining department fabricates parts for both the Consumer and Commercial Divisions for Toro, with special emphasis on complicated machining center work. As such, there are both numerical controlled (NC) lathes and machining centers in the shop.

There are two licensed seats of PAMS with three trained to use the system. The program itself is set up to run on 486 PCs. All Toro locations are interconnected by WAN, and engineering drawing data is imported via IGES.

Programming for the CNCs is through Pathtrace's PAMS milling and lathe programs. PAMS and its upgrades have been used at Toro since 1989 and have provided speed and ease of use necessary in their operation. Programming for the lathes is through PAMS four-axis turning module, which allows full 3D simulation of both upper and lower turrets. Special four-axis balanced and mirrored cycles have been implemented to fully exploit the high metal removal capabilities of their four-axis lathes. The software displays a separate machining instruction list for each turret side-by-side for ease of editing.

Provided with PAMS and written as a fully dBase IV compatible application, PAMS tooling allows comprehensive tooling data to be stored in a set of databases and retrieved into machining commands as required. Tooling can be built up as an assembly from inserts and holders, and kits of tooling can be assembled and associated with a machine tool turret.

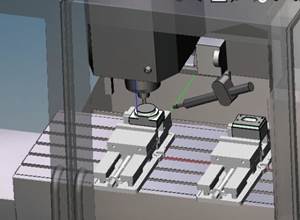

The milling program allows for a full three-axis control and provides additional contour milling cycles for machining pockets and profiles with contoured walls. All machining cycles are able to work in multiple construction planes (CPL), which can be created on the component model. Each CPL can have its own datum, including an indexing reference. It is also useful on programming large single components, such as castings, requiring machining on several faces.

A useful feature is macro code parametrics. The programmer can edit keyboard macros to include user variables. This allows the programming of "families of parts" by simply entering variable data. A very useful module is the postprocessor module, which allows preparation and compiling of postprocessor files for the various machine tools. The file also controls the CNC code generation and allows customization of the code as well, ensuring that any program fully reflects the capabilities of each machine tool.

Often in manufacturing plants, programmers have little or no control of their operation. With PAMS, the programmers at Toro are in complete control. Through an IGES format, engineering drawings can be imported from anywhere in the company. The software itself allows complete control over programming the various machine tools and keeps control of the machining operations right at the programmer's desktop. Toro likes to be known as being first in its respective industry. The programmers at Toro like to be known as first in using high tech tools in manufacturing leading edge products. Pathtrace's PAMS suite of software has helped both to realize their goals.

Related Content

Fearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreHow Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More