The idea at GE Aviation was simple—collect the alarms and messages generated by the CNC units on a group of machine tools and then correlate this information to the machining processes being executed at the time. The goal of this pilot project, conducted at two of GE Aviation’s manufacturing plants, was to develop a communications tool that would provide manufacturing cell leaders, machine operators and maintenance personnel with better insight into how well their machines were actually performing. This would help them identify opportunities to fix or improve the machines and processes.

The key "enabling technology" to be used and tested in this pilot project, initiated in June 2009, was MTConnect (mtconnect.org), a standardized communications protocol designed to make it easier to collect, transmit and leverage data from discrete equipment such as CNC machine tools. "We suspected there was a gap between our machining process plans and our machining results. Closing those gaps in our shops and cells would significantly improve machine utilization and reduce both maintenance downtime and manufacturing cost," says Jim Dolle, who manages the Metal Working & Manufacturing Technology engineering group headquartered at GE Aviation’s Evendale facility in Cincinnati, Ohio. Mr. Dolle’s group is spearheading the pilot project as part of a much larger effort to improve GE Aviation’s machining capability. "We wanted to develop a tool that enables a manufacturing cell to easily measure the actual part production time, including all unplanned events, against the planned time and to do so on a routine basis," Mr. Dolle says. MTConnect helps them do that.

This standard made it possible to collect data about CNC-generated alarms and messages in a format that could be saved, organized and analyzed. "Just getting the types of alarms and the time stamps as they were occurring into a spreadsheet helped us see why certain machines weren’t doing as well as they should. More importantly, we could start quantifying the effects of what was happening," Mr. Dolle explains. "When a cell leader can point to a sticking tool changer on a machine and put a price tag on the lost cycle time, it really gets attention," he says. Cell leaders can use this kind of information to help set priorities for maintenance activities and to justify capital equipment improvements, Mr. Dolle adds.

This is just the beginning. The initial results of the pilot project with MTConnect were so encouraging that cell leaders and methods engineers have identified additional machines to be monitored and new functionality to be incorporated into the system. "MTConnect will make it possible for most of our CNC machines to feed performance data into a process monitoring system," says Ray Peterson, the senior technologist in the software engineering group that did the development work on the initial phase of the project. "MTConnect makes this connection at the machine tool level rather simple and low cost. The challenge will be handling all the usable data and supporting the users of the data," he says.

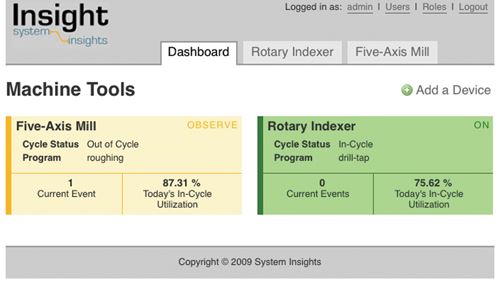

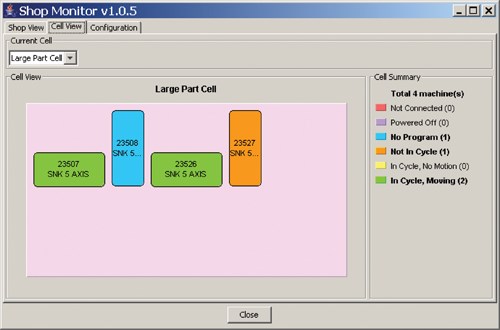

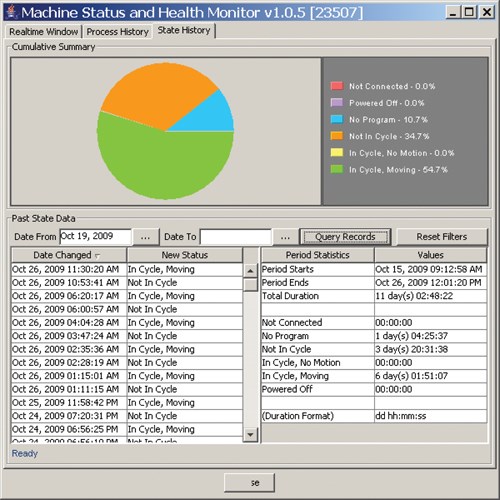

Similar experiences and results are reported by Remmele Engineering, a well-known and widely diversified job shop in the Minneapolis, Minnesota area. This shop’s pilot project used MTConnect on two very different types of machine tools—a ten-station rotary transfer machine and a large, five-axis HMC. "We wanted to see how getting process and utilization data from a high-volume production machine used for medical parts as well as a low-volume, high-mix machine for aerospace parts would help us," explains Mark Conley, manager of Remmele’s CAM/EDI center. In both cases, operators and production managers are gaining important insights into the performance of these machines, he reports.

Of course, GE Aviation and Remmele are not the only end-users currently implementing MTConnect on some level. However, the representative experience of these two users makes a strong statement about what the developers and proponents of MTConnect have been touting: that it creates an effective bridge by which data from manufacturing equipment can easily cross over to the applications that make factory-wide or shop-wide integration possible.

John B. Byrd III is president of the newly formed MTConnect Institute and former president of AMT—The Association For Manufacturing Technology (amtonline.org), which provided critical support for the MTConnect development effort under his leadership. "MTConnect is off and running," he says. "A growing number of equipment suppliers are offering MTConnect-compliant products. Likewise, application developers are creating software to use MTConnect data for analysis and reporting. Meanwhile and most importantly, end users are embracing it." According to Mr. Byrd, the gathering momentum behind MTConnect is critical. "One reason why standards fail is because suppliers hold back waiting for user demand to materialize, while users hold back waiting to see if enough compliant products and applications will be ready for them to jump on board. Today, both camps are succeeding with MTConnect."

Commenting on the promise he sees with MTConnect, Red Heitkamp, director of advanced manufacturing engineering at Remmele, is even more direct. "It’s a game changer for the future of manufacturing," he says.

Somebody Had To Do It

MTConnect has its roots at AMT. The members and administrators of this organization, which represents machine tool builders and other manufacturing technology suppliers, became aware of the need for interoperability when experts from the computer industry were invited to discuss the needs of manufacturing at its fall 2006 annual meeting for members. The message from these experts was blunt: Unless machine tools and other types of computerized manufacturing equipment can readily communicate critical data in a standard format, the industry cannot automate rapidly enough to keep up with global demands. Integration on the shop floor would be difficult or impossible. Progress in productivity gains and cost reductions would be stymied.

The response to this wake-up call was the MTConnect project, for which AMT put up more than a $1 million in seed money in January 2007. The committee formed to pursue this initiative brought together computer science researchers from the University of California-Berkeley, the Georgia Institute of Technology and other institutions to conceive, design and develop a draft communications standard. Paul Warndorf, AMT’s vice president of technology and liaison to the MTConnect development committee, recalls highlights of that development effort. "Early on we knew that the standard would have to be open and extensible; use existing standards such as XML or HTTP borrowed from the Internet; be easy to understand and implement; and not conflict with proprietary communications technology already in place. So that’s how we made it."

A working draft of the MTConnect standard was proposed in the summer of 2008, in time for at least two dozen equipment manufacturers to implement it on machines displayed at IMTS 2008 in September. All were interfaced to a single network application that instantly displayed the operational status of any selected machine. This successful demonstration was the centerpiece of the show’s Emerging Technology Center. The quick response of participating exhibitors not only proved that the concept worked, but it also validated the importance of keeping the concept simple.

Following the success at IMTS, the standard was officially published in December 2008. As it is, MTConnect establishes specifications for formatting, tagging and transmitting data generated by a processor on a piece of equipment. It also specifies a data format that describes what data is available, along with the structure of the device. This enables the devices and applications to know the capabilities of the machine and automatically recognize what data can be communicated.

As Mr. Warndorf notes, "It’s important to understand that MTConnect does not imply anything about how the data might be used. That’s up to the equipment suppliers, software developers and end users. MTConnect makes the data accessible and able to be shared in a neutral format." He emphasizes that MTConnect is not an application—it’s not software that "does something." This standard is designed to make it easier for devices and systems to talk to each other. What software running on those devices or systems does with the data is left to the ingenuity of developers. With MTConnect, interfacing computerized manufacturing equipment to monitoring systems or to systems that let machines and accessories interact becomes very nearly a "plug-and-produce" scenario.

Getting Smarter With Better Data

Data accessibility was the factor that made GE Aviation look closely at MTConnect. GE Aviation, whose prime mission is to build jet engines for commercial and military customers, has more than 1,000 machine tools in numerous plants throughout the country. These machines are connected through a centralized DNC system supported by the same engineering group responsible for defining and implementing the latest in machining technology. Using MTConnect to enhance the DNC system with machine status and alarm monitoring functionality was a natural extension.

The MTConnect pilot project is an important step that supports GE Aviation’s ongoing effort to deploy what it calls Smart Machining Technology. This effort includes optimized cutting tools, improved toolpath programming, best-practice machining parameters, streamlined setup procedures and comprehensive monitoring systems. The goal is to reduce effective cycle time by as much as 30 percent. According to Mr. Dolle, two challenges for Smart Machining are to develop more efficient machining processes and to ensure that the machines in service are capable of operating within an acceptable process window to produce parts correctly. "We want an objective, unbiased method that the cells can use to evaluate their machines’ capabilities, to identify opportunities and to measure improvements for machining processes," Mr. Dolle says. "We believe that performance data from the machine tools could give them this information—if the data could be accessed." For this reason, developing a system to monitor machine tool health and status is a priority. Ultimately, the plan calls for real-time data diagnostics—that is, instant feedback that shows how well a machine is performing. When Mr. Peterson attended an informational session about MTConnect in early 2007, he could see how this communications standard could facilitate development of the machine monitoring system they were seeking.

"The first draft of the MTConnect standard included definitions for alarms and error messages," Mr. Peterson notes, recalling what he learned about MTConnect. "We saw an opportunity to create an application to collect alarm and message data from machine tool CNCs and save them in a database," he says. This application could be developed in-house within an existing set of applications, a task Mr. Peterson took on. This Java-based application was written and installed on the network file server at the Evendale facility by mid-summer 2009. It is the basis for a functioning machine monitoring system.

Eight machines were selected for monitoring in the pilot project. These included four five-axis VMCs at one plant and four turn/mill machines at another plant several states away. The machines in each group are nearly identical and are equipped with the same model CNC: Fanuc 15s and Fanuc 30s, respectively. Mr. Peterson developed an MTConnect adapter for each type of control. This adapter, which runs on the PC connected to each control unit, "talks to the control unit in its native protocol, then passes the data to an MTConnect agent," Mr. Peterson says. The MTConnect agent, which Mr. Peterson also developed, formats the data in XML and interfaces with the application on the database server. The agent provides a universal interface for any future adapters that are created.

Once these pieces were in place, the group began collecting data. Initially, the adapters were designed to pass only data related to alarms and messages generated by the CNC. The type of alarm, the time it occurred and its duration are recorded in an SQL database. This database can be queried using a variety of common database analysis tools to create histograms or Pareto charts. Data can also be imported into spreadsheet applications and word-processing documents.

"Right away, this data gave us a more complete picture of how these machines were performing," Mr. Peterson says. Because each group consisted of the same type of machine, differences in cycle times, utilization and reliability became apparent. The sticking tool changer on one machine, for example, was easy to spot. Correlating the alarm and message data with the machining process timestamps, however, was more revealing. "Now we could see what impact certain events were having on productivity," Mr. Peterson says.

The pilot project has proven the feasibility of implementing MTConnect as a data collection enabler. A number of next steps are being evaluated. "By modifying the MTConnect adapters, we can extract other data, such as when feed-rate overrides are applied. We are also looking at pulling in the probing data that is currently being used in a closed-loop machining system," Mr. Peterson reports.

Visibility in the Job Shop

Remmele Engineering became interested in MTConnect for many of the same reasons that GE Aviation did. For example, the company wants factual data, not guesswork, to make decisions about manufacturing processes and machine tool performance. Like GE, Remmele launched a pilot project using MTConnect as the enabler that makes data from machine tools accessible. The results have been very positive. Mr. Conley, who oversees how Remmele uses manufacturing software, says MTConnect "takes the lid off manufacturing data not available before."

The two pilot projects, however, had significant differences that highlight further aspects of MTConnect’s value to an end user. The most striking is the involvement of a third-party software application developer. Although Remmele is a remarkably capable contract manufacturing company and a sizable one (with four facilities and about 500 employees), it does not have the extensive information technology resources that GE Aviation does. To expedite the MTConnect pilot implementation, Remmele brought on board System Insights, Inc. (Berkeley, California), a software development company recently founded by Will Sobel and Athulan Vijayaraghavan, who were members of the team that created the original MTConnect specification for AMT. This step does not limit the company’s options, however. Bill Blomquist, the administrator of Remmele’s pilot project, explains: "The beauty of MTConnect is that data always remains in a neutral format. With MTConnect, we are not tied to one software developer or application vendor." Remmele works with several software providers whose applications are likely to benefit from access to machine tool performance data, he says. A neutral data format preserves flexibility in this multi-vendor environment.

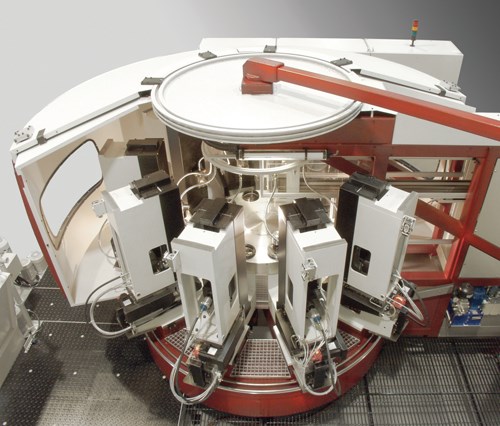

Another difference is Remmele’s choice of a rotary transfer machine and a five-axis HMC for the pilot project. The very dissimilar machines reflect its particular needs as a job shop serving customers in widely disparate industries. They also provide an opportunity to test machine monitoring in different contexts. For example, because the company relies on the rotary transfer machine, a Hydromat AT, for high-volume production of a critical medical part, keeping all ten machining stations at optimal performance is a high priority. A single station that has a maintenance issue or experiences unplanned downtime can disrupt production and jeopardize timely delivery of the product.

Finally, Remmele is keenly interested in data from machine sensors that are not part of the CNC system. An MTConnect compliant temperature sensor was used to measure workpiece temperature during a pilot study. It worked fine.

Implementing MTConnect on the rotary transfer machine required a collaborative effort between the specialists at Hydromat (St. Louis, Missouri) and System Insights. In this case, Tom Hansen, general manager of electrical engineering at Hydromat, developed the MTConnect adapter. It resides on a PC connected to the central processing unit that coordinates the independently controlled machining paths at each station. By design, this adapter is configured to select only certain types of data for MTConnect formatting. It was determined that the adapter would pass alarm messages, cycle starts and cycle stops (with their time stamps) from all machining stations. It would also pass true position feedback from the first station, where mechanical accuracy is established. The adapter must also tag data according to the station that originates it. Likewise, the adapter recognizes which station has a bar feeder, parts catcher or other peripheral device because alarm messages related to these devices are also passed to the MTConnect agent.

Remmele plans to install a temperature sensor on this machine’s oil chiller to be monitored via MTConnect.

Mr. Vijayaraghavan, CTO at System Insights, configured the MTConnect agent to ensure that data passed by the adapter is compliant with the MTConnect standard and can be retrieved by the machine monitoring system. The application software developed by System Insights was customized to suit Remmele’s specifications for the pilot project. This software organizes and analyzes MTConnect data from both the rotary transfer machine and the five-axis machining center.

The machining center, a Toyoda FA630, is located at the company’s aerospace and defense division in Big Lake, Minnesota. This machine is dedicated to large, complex workpieces for commercial and military aircraft. Whereas complete parts drop off the rotary transfer machine in seconds, workpieces processed on the HMC typically require as many as six hours of continuous machine time. System Insights developed the MTConnect adapter and configured the agent for this machine, which is equipped with a Fanuc CNC.

Remmele’s pilot project commenced in earnest in April 2009, and by August, the adapters, agents and machine monitoring application were operating.

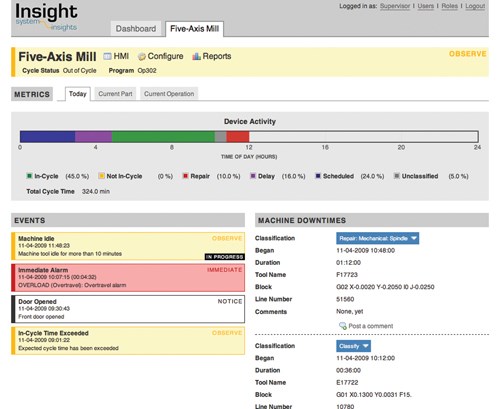

A look at the machine monitoring application created for Remmele brings out some important observations. As noted earlier, MTConnect data is "fed into" this application from the machine tool controller via the MTConnect agent. The application, in turn, "digests" the data for the user’s consumption. The MTConnect standard does not address this process in any way. System Insights developed the monitoring system so that data could be organized and presented in a way suitable to support different types of visualization and analysis. For example, Remmele finds it very valuable to track data from the transfer machine against targets set in the company’s ERP system. In contrast, data from the HMC helps the company track multiple operations against targets set in the process plan for each part number. As Will Sobel, CEO of System Insights, explains, "Data about machine performance has to be organized and presented in ways that specific users can interpret and use to take action. These needs can be very different depending on the role of the person in the organization. The challenge is to turn data into information and make it valuable to the user."

Remmele Engineering is still in the early stages of discerning how to use this information in the best way. However, even in its initial development phase, the machine monitoring system helps the company see what is really going on at the machine being monitored. "Everybody understands the value of this communication," says Mr. Conley. "For the operators, it is helpful to have objective data that gives reasons for results from the shop floor." He also reports that manufacturing engineers are very interested by the prospect of being able to validate process plans and evaluate process innovations objectively.

Mr. Blomquist says the visibility into machine performance that the system provides gives the company a reliable snapshot of how well machines are performing. "If a machine is idle or a transfer station is falling behind, we’ll be better able to find the reason."

On The Verge

The MTConnect pilot projects at GE Aviation and Remmele Engineering put both companies on the verge of wider implementation of a machine monitoring system. Both companies intend to expand the kinds of data that can be extracted from the CNCs. Likewise, both companies envision other ways to use MTConnect to integrate their machining operations.

Both companies are actively involved in the development of the MTConnect standard by participating as members in the Technical Advisory Group and serving on MTConnect Working Groups. The Working Groups consist of representatives from member companies of the advisory group who have a special interest in various areas of enhancement to the standard. Because MTConnect was designed to be extensible, its naming, tagging and defining conventions can be readily applied to many kinds of manufacturing equipment as interested parties come to agreement. Current working groups are addressing issues regarding support for complex machine tools such as turn-mills and multitasking machines, compliance testing/certification, robotics and the integration of tool presetters or other "mobile assets."

MTConnect is also designed to be an open-source standard. As such, users and developers are encouraged to freely share their MTConnect software utilities and toolkits with other users and developers. For example, System Insights is developing a high-speed data storage tool so that large volumes of data can be archived and analyzed in near real-time without impeding the function of the machine tool controller. The company plans to share this tool as a free download from their Web site (systeminsights.com) once it is complete.

So, what’s next for MTConnect? The activities of equipment suppliers and end users indicate that the standard is indeed on the verge of taking the manufacturing industry to a new level of automation and integration. Outside observers from the computer industry and expert insiders from the manufacturing industry would have to agree that "it’s about time." Mr. Byrd is particularly bold about the prospects for MTConnect.

He says, "MTConnect will have a greater impact on manufacturing in the 21st century than numerical control had on manufacturing in the 20th century."

.png;maxWidth=300;quality=90)