Pallet Adjusts To Different Tool Diameters

A tool-handling device developed for more efficient automated production of cutting tools may also be helpful for machine shops that have their own in-house area for tool regrinding or making custom tools.

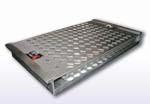

A tool-handling device developed for more efficient automated production of cutting tools may also be helpful for machine shops that have their own in-house area for tool regrinding or making custom tools. An adjustable tool pallet from Active Automation (Elk Grove Village, Illinois) holds tools of various diameters. The pallet reduces the various costs associated with storing and retrieving dedicated pallets for different sized holes.

To understand how the adjustable pallet works, it helps to understand why it was developed. Increasingly, the tool and cutter grinders used to manufacture rotary tools such as drills, end mills and reamers are served by free-standing robots or integral pick-and-place attachments that automatically load tool blanks into the grinder and unload the finish-ground tools. Usually, the blanks and the ground cutting tools are held in pallets that have a grid of holes drilled to the size (diameter) of the tool being produced. Depending on the space availability, separate pallets may be used to hold the blanks and finished cutting tools, or the same pallet may be used to hold both.

When production switches to a different tool diameter, the pallet must be changed for one with appropriately sized holes. Because of the many standard English and metric tool sizes, the cutting tool manufacturer quickly accumulates a large number of pallets, which must be stored in such a way that they can be quickly located and accessed. The setup person must return the pallet used for the job just completed to the pallet storage area, locate the pallet with the hole size required for the next job, and install it at the machine. If the manufacturer receives an order for a tool size and does not have the appropriate pallet, the manufacturer must buy or make a pallet drilled to the correct hole size, which can delay the start of the job.

The adjustable tool pallet simplifies handling of various sizes of cutting tools by adjusting to the diameter of the current tool. The top of the pallet consists of a stack of three plates, each with a grid of square or octagonal holes. A thumbwheel adjusts the relative position of the plates: The top and bottom plates move in one direction while the middle plate moves in the opposite direction, reducing the resulting opening to the size of the round or multi-sided tool being processed.

The relative movement of the plates is such that the centerline of the opening for the tool remains constant. As a result, the programmed movement of the robot or pick-and-place device does not have to be adjusted to compensate for a different tool diameter. The standard adjustable pallet accepts tool diameters from 0.025 inch to 0.500 inch; specials can be ordered capable of handling tool diameters to 1.25 inches. Because space for the pallet on the tool and cutter grinder varies from manufacturer to manufacturer, many pallet models are available to fit AAI, ANCA, Rollomatic, Unison, Walter and other tool and cutter grinders. Active Automation recommends that the pallets be purchased in pairs to avoid downtime caused by idling the machine when inserting blanks in and unloading finished tools from an only pallet.

Sam Marinkovich, president of Active Automation, notes that for cutting tool manufacturers, the adjustable tool pallet represents a significant cost savings: It replaces 13 or more conventional pallets, each of which can cost $350 to $800 depending on the manufacturer. Ability to use the same pallet for different tool sizes helps to minimize downtime for setups and saves time that would otherwise be lost moving pallets in and out of storage. Just as importantly, the automated loading and unloading of cutting tools from the adjustable pallets through the various production steps reduces handling by operators, resulting in fewer injuries and less in-process damage to expensive tools. Similarly, the adjustable pallet will benefit machine shops and other shops involved in tool grinding.

Related Content

Buying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreNew Machining Technology Works With Old to Restore WWII Submarine

A set of donated boring bars that can be used in a 1954 boring head will enable volunteer machinists to recreate a pair of binoculars for the USS Pampanito.

Read MoreAll-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)