The late 1840s marked the dawn of the clipper, a small, square-sailed type of merchant ship built primarily for speed. This design’s spurt in popularity nearly two centuries ago was due to an advantage no less appreciated by modern businesses: the ability to deliver goods faster than the competition.

Thus, “Clipper Industries” might seem an especially fitting moniker for a machining and fabricating shop. Ironically, however, meeting delivery goals for some parts had been problematic for this Chicago-area company—that is, until recently. Adding a VF8 VMC from Haas Automation (Oxnard, California) with an A6040SD automatic pallet changer (APC) from Midaco (Elk Grove Village, Illinois) has reduced lead time by more than 75 percent and machining costs by as much as 50 percent in some cases. “We estimate we have saved thousands of dollars since adding the machine and APC,” says Chuck Potter, general manager at Clipper.

Clipper Industries traces its roots to the end of World War II, when three members of a team of engineers became close friends and decided to go into business together. Their first project was designing and marketing a trailer they named the “Clipper Cadet.” In 1946, they incorporated the company under its current name in honor of that flagship product. During the next few decades, Clipper continued to expand its business and clientele, eventually moving to its current 50,000-square-foot facility in Itasca, a suburb of Chicago. Today, it provides fabricated and machined parts for industries including dental equipment, construction, commercial floor sweeping, industrial stitching, agricultural equipment and more.

Prior to adding the Haas VF8 VMC and Midaco APC, the company used a variety of manual equipment to process low-volume machining orders and outsourced most high-volume orders. However, the limitations of this approach began to take their toll during the recent economic downturn, which brought increased market demand for lower prices and faster deliveries. In addition, suppliers were asking for price increases that Clipper did not want to pass on to its customers.

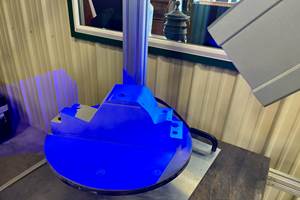

An automated CNC machining center, the company reasoned, would enable it to keep work in-house and reduce both machining cost and part lead time. Research and consultations with industry experts led the company to the VF8 and Midaco APC. Specifically, the company needed a large-bed machining center and an APC with 60-by-40-inch pallets to accommodate multiple parts. “We liked how Midaco offered a pallet to fit the exact size of the machining envelope,” Mr. Potter says.

The primary advantage of the two-pallet APC is that operators can load parts on one pallet while other is in the machine, says Randy Rothe, an engineer at Clipper who does most of the setup work on the new VMC. This significantly reduces downtime for both the machine and operator. “If you’re loading parts through the front door of the machine one by one or two by two in vises—the old way—then the operator is standing there waiting to do the change-over after the machine stops,” he explains. “The automated pallet changing system enables the operator to keep unloading parts and setting up new jobs while the machine runs. The operator also no longer has to lean into the machine, so it is a whole lot safer all the way around.”

The fact that the system automatically exchanges pallets in less than 30 seconds with ± 0.0001-inch repeatability amplifies these time savings, Mr. Potter adds. “There is virtually no downtime between loads, and this increases both machine and operator productivity.”

Upon receiving the new system, the company added an identical pattern of tapped and dowel-pinned holes to both pallets. That makes indicating setups faster and easier, Mr. Rothe says. For instance, when both pallets are not being used in a production situation, the company can mount vises on one and fixtures on the other. “Indicating three vises in the machine would take half an hour to an hour,” Mr. Rothe says. “By presetting our pallets and using the tapped-hole patterns, I can just throw in an M code, and in 30 seconds, or a minute at most, I’ll have my vises or fixtures indicated and ready to go.”

This capability is especially useful when the company has to interrupt production to accommodate emergency customer orders. Mr. Rothe cites a hypothetical case in which the company is working on a job that uses fixtures and the emergency parts can be held with vises. “Because the vises are already indicated on our pallet, we can get our customer out of trouble quickly, then we can shuttle the tables out and quickly switch back to what we were doing,” he explains. In contrast, without the APC, the operator would have no choice but to remove the fixtures and mount and indicate the vice.

In fact, Mr. Rothe estimates that the company saves six to eight hours per week on daily vise changes. At $75 per hour, that adds up to more than $23,000 per year from only reductions in vise change-over downtime. Overall, the system has reduced machining costs by 30 to 50 percent for the work the company brought back in- house, while processing lead time has decreased from an average of two to three weeks to only a few days.

“When we first researched a new CNC machining center and the idea of a pallet changer, we were like many companies that thought: ‘We don’t need a pallet changer because we don’t do high-volume production machining,’” Mr. Rothe says. “Well, if you are using vises or repeat-use fixtures, and if you have to move vises on and off the table three or more times per week, that takes a considerable amount of time. If you’re running fixtures and short-run work with vises, you’ve got to have a pallet changer on your machining center.”

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)