Porous Steel Improves Mold Venting

Entrapment of gases during plastic injection is a problem that continues to challenge the design capabilities of moldmakers. The increasing complexity of tooling demanded by today's manufacturers dictates that many areas inside molds are quite difficult to vent adequately.

Entrapment of gases during plastic injection is a problem that continues to challenge the design capabilities of moldmakers. The increasing complexity of tooling demanded by today's manufacturers dictates that many areas inside molds are quite difficult to vent adequately. Gases compressed in these remote pockets can scorch finished plastic parts and cause "short shots" or incomplete filling of the mold. Trapped air also causes shrinkage that produces ripples or depressions in finished parts. Additionally, the strong back pressure produced when filling molds that incorporate conventional venting channels can retard plastic flow rate.

Conventional methods that employ parting-line vents, vent plugs and pins sometimes lack sufficient capacity to handle the large volumes of gases generated during molding operations. To address this problem, International Mold Steel, Inc. has developed a sintered, porous metal product that comprises 25 percent air by volume. Porcerax II incorporates a network of interconnected pores that allow trapped gases to permeate the steel. This property makes the product useful for targeted venting of difficult-to-access mold areas.

Porcerax II is available with pore sizes of 3, 7 or 20 microns to meet different applications. (Molds injected with natural rubber or talc-filled resins, for example, are best suited for the 3-micron type. Common resins such as ABS, polypropylene, soft PVC, polyethylene, acrylic, polyurethane and styrene are well suited for the 7-micron pore size. The 20-micron grade was developed for applications where substantial venting is required and where the mold steel will have a milled finish.)

To maintain the material's permeability, users must observe some guidelines that are not applicable to conventional metals. Grinding, for example, closes the surface pores in all grades of Porcerax II. Milling will close pores in the 3- and 7-micron grades, and it significantly reduces the pore size in the 20-micron grade. Additionally, this material cannot be welded.

Although stoning and polishing the surface (with occasional flushing) restores the material's permeability after machining, wire or ram EDM is the best method to restore surfaces. If WEDM is used for this purpose, however, the machine's wire-winding speed should be increased to prevent breaking the wire because of arcing across gaps in the porous material.

Because of its porous structure, periodic cleaning of Porcerax II is essential for optimum results. Although it may be cleaned by simply brushing acetone, mold cleaner or another cleaning solvent onto its surfaces, for best results the material should be cleaned in an ultrasonic cleaning unit filled with acetone.

Depending on a mold's specific venting requirements, this material may be used to fabricate a single insert—or perhaps an entire mold half. For proper venting, the manufacturer recommends that a minimum of 10 percent of the core and cavity's total surface area be composed of Porcerax II.

The material's native hardness is 35-40 HRc, but it may be heat treated to a hardness of 50-52 HRc. Heat treatment should be performed in a vacuum furnace. This material cannot be tested with either a Rockwell or a Brinell hardness tester because its porosity will give false readings.

This material can also eliminate some time-consuming steps for moldmakers and end users. For example, when conventional steel is used to fabricate a mold cavity, trapped air produces a glossy surface finish on the part. Because many manufacturers today specify matte finishes, this may create the need for a secondary spray-painting operation. This is not necessary when the porous material is used, because improved venting gives the part a matte finish when it comes out of the mold.

By lowering injection and back pressures—thus reducing mold-cycle times—fewer drops are needed to assure proper filling of the mold. This simplifies mold design and may allow the entire hot-runner manifold to be eliminated. The porosity of this material also facilitates part ejection when the molding cycle is completed.

Related Content

For This Machine Shop, Licensing Is the Answer to the Inventor’s Dilemma

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

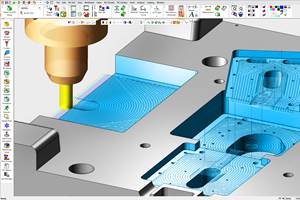

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreTool and Die Shop Discovers New Opportunities With First CNC Machine

In a shop that stamps millions of parts per year, the arrival of a CNC machining center is opening new pathways for production and business.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)