Precision Metal Fabricator Depends On Multimedia Software To Maintain

Electrolabs, Inc., used to have problems making sure that machine and tooling setups were done right the first time and that parts were assembled correctly. Then the company began using the Realtrac real-time shop management system and is now able to utilize the improved multi-media capability of Realtrac to link actual pictures of parts to jobs and router operations.

Electrolabs, Inc., a precision metal fabricator in Fraser, Michigan, used to have problems making sure that machine and tooling setups were done right the first time and that parts were assembled correctly. Electrolabs specializes in prototypes and small production runs. It offers a complete range of sheet metal processing services from design and layout to painting and silk-screening. Although about 50 percent of its work is at least partially repetitive, many of the shop employees cannot read prints, and the company had no easy way to describe the required operations and setups.

Then the company began using the Realtrac real-time shop management system from Realtrac (Irvine, California), and with recent advances in digital camera technology, Electrolabs is now able to utilize the improved multi-media capability of Realtrac to link actual pictures of parts to jobs and router operations. “A picture is worth a thousand words,” says Dennis Suddon, president of Electrolabs. “How many things can a person remember? If I don’t have a print to show someone, I can give him a picture.”

Using a Sony MVC-FD8 digital camera, a picture is captured of many parts in various stages of completion as well as a picture of practically every finished part. For example, without hunting for paper, paint shop employees will know they are working on the right assembly by bringing up a picture on their PC screens. This helps assure that the finishing is always done the same way for a specific part. When setting up operations, employees know exactly what tools and setup to use by viewing a digital picture. Also, pictures are often sent electronically to customers for reference when discussing future orders for the same or similar parts.

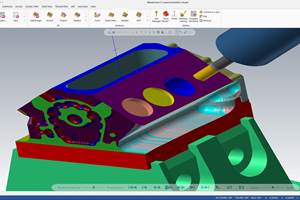

Before linking an image to a specific operation on the Realtrac job router, Electrolabs can edit the image using Paint Shop Pro and add dimensions and a typed description. Electrolabs also stores images on floppy disks for backup and future reference. In addition to digital pictures, Realtrac can be used to link scanned images, CAD drawings and sound files (for example, voice description of setup procedures) to jobs and operations.

Electrolabs uses an Amada FBD III-8025 press brake system with fully automated controls. A PC with a touch screen monitor is used on the shop floor with both the Amada and Realtrac software, and Mr. Suddon has been able to integrate both systems so drawings and other information provided by the Amada system are transferred right into Realtrac. A PC at the Amada with a touch screen monitor allows operators to view images linked to Realtrac. Electrolabs currently is using the microterminal emulation feature of Realtrac, which allows workers to also use the Amada touch screen monitor to log on and off operations.

Mr. Suddon also has pioneered the linking of a Realtrac data collection terminal to a machine robot that can log on and off of specific operations.

Mr. Suddon feels that Realtrac has contributed greatly to the ability of Electrolabs to maintain a high level of customer satisfaction. Shop employees enter data as activities occur using Realtrac microterminals, so that machine loads, schedules and costs are maintained in real-time. When Electrolabs first implemented the system in 1986, Mr. Suddon felt if the company kept Realtrac for five years, it would more than recoup its investment. Now the company still depends on the system to track jobs and provide up-to-the minute information. Every morning, key staff people review Realtrac screens that tell them what has to be done that day.

Mr. Suddon especially likes Realtrac’s flexibility to do a job the way he wants to do it. Operations can be changed and added on the shop floor or moved to a different machine than planned. Although Realtrac offers an estimating and quoting module, Mr. Suddon needed a system that allowed it to take advantage of its existing estimating procedures and formulas and the vast amount of historical data it had accumulated. So, with the help of an outside consultant, a custom estimating program was developed that integrates directly with Realtrac. MMS

Related Content

CAD/CAM System Requirements: An Overview

CAD/CAM programs are among the most demanding kinds of computer software. Smooth operation requires careful consideration of computer specifications.

Read MoreHow to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

Read More5 G-Code Tips for Increasing CNC Efficiency

Optimizing G code is a low-cost way to improve CNC efficiency without sacrificing usability and safety.

Read More5 Reasons Why Machine Shop Ownership Is Changing

Mergers, acquisitions and other ownership changes are an effect of Boomer-age shop owners retiring, but only in part. Also important: The way we think about machining has changed.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)