Predictive Maintenance And Machine Tool Calibration Techniques

Here are some of the tools and techniques for making sure machine tools stay at peak performance levels.

Reducing machine tool downtime and assuring quality have become increasingly important as the demand for higher production rates and closer tolerances continues to grow. To assure maximum performance from machine tools, manufacturers are increasingly employing predictive maintenance (PDM) programs.

The objective of PDM and similar programs—such as Machine Tool Variability Management System (MTVMS), Reliability and Maintainability (R&M), Failure Mode and Effective Analysis (FMEA) and Total Productive Maintenance (TPM)—is to predict when a machine tool will fail or go out of tolerance in order to reduce unplanned downtime, particularly at critical times during production. This objective is achieved by monitoring machine tools and collecting data with a combination of instruments, such as calibration, vibration analysis and infrared thermography equipment. A historic comparison of the data is made and used to predict both when a machine tool will require service and the scope of services that will be necessary. Therefore, repairs and other maintenance can be scheduled for time periods which will least interfere with production.

Although PDM programs are designed to reduce downtime, extensive diagnostic procedures can take machines out of service for longer periods than some manufacturers want. So a new quick-check technique is being integrated with PDM programs to reduce machine tool downtime to a minimum. A quick-check tests the machine tool's volumetric accuracy with laser measurements. Using newer laser calibration equipment, such checks can be performed without having to remove covers or other components of a machine tool.

What's Driving Predictive Maintenance

The trend toward PDM programs is driven by a number of factors, including the migration from manual to CNC machine tools, higher production rates and higher quality requirements. Today's CNC machine tools have faster spindle speeds, feed and rapid traverse rates, and acceleration/deceleration rates, yet must also achieve higher positioning accuracy. Consider, for example, the increases in machine tool speed and precision that have occurred over the past 30 years. As Figure 1 shows, the requirements have grown very high indeed.

| Figure 1-- Machine Tool Performance Trends | ||||

| Year | 1960s | 1970s | 1980s | 1990s |

| Velocity (ipm) | 200 | 400 | 800 | 3,000 |

| Acceleration (g's) | 0.2 | 0.2 | 0.6 | 1.5 |

| Rotary Axes (rpm) | 2 | 4 | 8 | 33 |

| Spindle Speed (rpm) | 4,000 | 6,000 | 15,000 | 20-40,000 |

| Tool Change Time (sec.) | 30 | 10 | 2/4 | 2/4 |

| Accuracy | ±0.002" | ±0.001" | ±0.0005" | ±2µm |

| Repeatability | ±0.0005" | ±0.0003" | ±1µ | |

Total Quality Management (TQM) and ISO 9000 programs also drive the need for PDM programs. Such quality management disciplines emphasize finding proof that machining processes are inherently capable of meeting accuracy requirements, which ultimately serves to reduce both rejects and the need for final inspection. TQM and ISO 9000 include a requirement for maintenance program procedures to assure that machine tools continually perform at a high level. The rationale is that if the process is correct, then the part will be correct.

How PDM Programs Work

In a typical PDM program, each CNC machine tool is checked twice a year for accuracy and vibration characteristics. Then an analysis is made by comparing the baseline data, past data and new data. Finally, a prediction is made for when the machine tool should be calibrated, when ballscrews or a spindle must be serviced, and so on. These corrective actions can then be scheduled at a time not critical to production, or immediately if necessary.

For example, a machine tool which has to maintain a tolerance of 0.0002 inch is checked every six months. At each of the last three inspections, the tolerance has been off by 0.00002 inch. Based on the historical information, a prediction can be made that, though the machine tool has appeared to remain stable, it will still need to be calibrated within one year. Similarly, vibration analysis will reveal much about the condition of the spindle and other critical components, and that information is used to make maintenance and repair predictions.

The quick-check technique allows volumetric accuracy of a machine to be evaluated with diagonal displacement measurements. A laser beam is directed from corner to corner of the work zone. As the machine executes a test movement pattern, the instrument reveals errors in squareness, as well as in linear position, reversal, pitch and yaw.

Establishing A Predictive Maintenance Program

Establishing a PDM program is a long process. It includes many steps, the first of which identifies which machine tools will be in the program. Then technologies required to monitor the machine tools and collect data—such as calibration, vibration or infrared thermography equipment—must be identified and agreed upon. Next, specific equipment has to be evaluated and selected.

After equipment has been purchased, PDM procedures must be established. The basic elements of the PDM program include:

- Monitoring machine tool conditions,

- Diagnostics to identify problems,

- Data analysis and corrective actions, and

- Early warning and prediction by performance and integration of precision measurement systems directly into the manufacturing operation.

After the program procedures have been defined, a criteria must be specified to determine acceptable performance and accuracy. Machine tool baseline conditions have to be identified. Routine machine tool measurements are then taken periodically and data collected. A trend analysis of the data is made. From the analysis, maintenance predictions and scheduling are made. Finally, error correction is performed according to need and schedule.

The Basic Tools Of Machine Tool Calibration

Perhaps the most important enabling development in PDM technique is the advent of practical instruments by which the performance of machine tools can be reliably measured. Much has been learned in the relatively short history of this technology.

In the past, the accuracy of a manual machine tool was largely a function of the operator's ability to precisely turn crank handles, and thus there was no way to calibrate or statistically determine the capability of the process. With the advent of CNC, however, it became imperative to verify actual position with the control and to compensate for error. And so arose the need for new calibration tools.

Early machine tool calibration techniques used a comparator and mechanical artifacts, such as a mechanical square, to measure static accuracy. But even under optimum conditions, the comparator has low resolution. And since any mechanical method is dependent on the operator for accuracy, human skill is still an issue. This is why the use of mechanical squares and comparators is limited today.

Another method of calibration is a grid plate encoder, which uses a non-contact reading head mounted in the spindle. It scans a circular path over the grid plate that is mounted on the machine table, and displays a plot of deviations from a true circle. The resulting plot serves as a guide to correcting errors in the servodrives and machine mechanisms, but only in two axes.

A double-ball bar system also measures dynamic path accuracy. This device is essentially a telescopic bar with a ball at each end. One ball pivots in a socket anchored to the table, while the other pivots in the spindle socket. During a circular path, changes in the distance between the two balls indicate roundness error.

Still another calibration instrument is the capacitor gage, which is used to measure thermal growth or runout of a spindle.

All of these instruments are extremely useful to a point. But the need for higher machine accuracies has driven demand for calibration systems that are more versatile and precise. The next generation of machine tool calibration equipment includes two different types of laser-based measurement systems—the laser interferometer and the laser Doppler systems.

The Michelson Interferometer

It may come as a surprise that the interferometer was invented way back in the 1880s by Albert Abraham Michelson. The first Michelson interferometer used a white light source, a fixed mirror and a movable mirror to precisely measure position. Later on, the white light was replaced by a HeNe (helium-neon) laser, and two corner cubes replaced the mirrors. Today, there are two types of laser Michelson systems used.

A single-frequency HeNe laser beam is directed at a beam splitter. Half of the beam passes through to a movable corner cube and the other half is reflected to a fixed corner cube. The reflected beams return and combine at the beam splitter. When all the optics are exactly aligned and motionless, these two combined beams will interfere with each other and generate an interference fringe pattern. A small area photo detector is used to count fringes. Each cycle of intensity change represents a half-wavelength of travel of the movable corner cube. If the laser wavelength is known, the travel of the movable corner cube can be accurately determined. The single frequency interferometer works reasonably well when the movable corner cube is in motion, but is "noisy" when it is still. So, air turbulence, electrical noise and gain drift cannot necessarily be distinguished from motion.

A two-frequency interferometer solves that problem. It mixes two HeNe laser beams of different frequencies to generate a carrier frequency. Therefore, the distance information is carried on AC waveforms, not DC like the one-frequency device. The two-frequency interferometer works very well. However, it requires heavy permanent magnets and precision optical components to preserve polarization and to minimize the scattered light from returning to the laser resonator. Because of the bulk of the system and number of optical components required, the cover has to be removed from most machine tools to enable calibration.

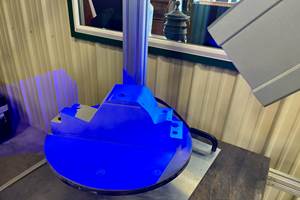

Laser Doppler Calibration System

Still another system utilizes a laser Doppler displacement meter (LDDM) for machine tool calibration. The LDDM uses electro-optics, optical heterodyne techniques and phase-demodulators to obtain the position information of a movable corner cube. This technology is based on 1950s microwave radar technology and 1970s laser technology. With LDDM systems, polarization and stray light are non-issues, and special optics are not required. Windows can be inserted in the beam path and simple mirrors can be used to reflect the laser beam to any angle. The compact system can be mounted on the table of a machine tool which eliminates the need to remove covers or machine components.

The major differences between the interferometer and Doppler calibration systems is that Doppler requires only two optics—a laser head and a retroreflector—while a laser interferometer requires three optics, one of which (the laser head) must be mounted on a tripod outside the machine tool. So the Doppler system is much faster to set up. Also, data collection with the laser Doppler system is automatic which can cut measurement time.

Calibrating Rotary Motion

Rotary tables require calibration, also. Conventional methods for calibrating rotary tables include using a rotary encoder, level and sine plate. But these methods are somewhat awkward and prone to error in comparison to more modern instruments. For example, every time a rotary table is checked with a sine plate, it has to be physically moved, so setup is time-consuming. Plus the sine plate is very expensive.

Laser interferometer and Doppler calibration systems can be used in this application as well. Here, the interferometer will require three optics and an indexing table, while the Doppler calibration system requires only two optics and no indexing table.

Purchasing Calibration Instruments

When purchasing machine tool calibration equipment there are a few simple rules to remember:

- Make sure the system will calibrate all of your equipment, so make a list of all your machine tools before you go shopping.

- Define the accuracies your machine tools must maintain, and make sure the calibration equipment is capable of measuring them.

- See a live demonstration on your machine tools before making a commitment.

- Make sure that operation of the equipment is within the skill range of your staff, and that there is adequate training available to learn it.

A Tool For Better Production

In the future, machine tools will feature on-line calibration systems. These systems will automatically take measurements and correct error while the machine tool is in production. The data also will be auto-matically collected and charted for later analysis to determine the machine tool's condition and to predict future maintenance requirements. On-line calibration will assure consistent and error-free machine tool performance and quality.

But that's the future. The good news is that relatively easy-to-use and cost-effective calibration systems are available right now. A regular discipline of quick-checks with these instruments, in combination with a broader PDM program, can help reduce machine tool downtime significantly. With the right "tools," a quick-check can be done in a few hours that will provide a valuable snapshot of how well that machine is going to be able to hold the necessary production tolerances, and for how long.

That puts a new level of control in the hands of manufacturing management—the power to continually keep production equipment process capable without any surprises along the way.

About the authors: Dr. Charles Wang is a founder and president of Optodyne, Inc. (Compton, California). Previously, Dr. Wang served as Senior Scientist at the Aerospace Corporation, responsible for developing high power ultraviolet lasers, stable chemical lasers and laser diagnostic techniques. As an adjunct professor at the University of California at San Diego he taught engineering physics for almost twenty years. Bob Thomas provides marketing services to the manufacturing and CAM software industries.

The Laser Doppler Calibration System

Optodyne manufactures a number of laser Doppler calibration systems which provide simultaneous linear and angular measurement, and squareness and flatness measurements for the calibration of machine tools. The Doppler calibration system requires only two optics—a dual-beam laser and retroreflector. These components are typically setup in the spindle and on the table of a machine tool, and measure the relative motion between the two. With the machine's control, a technician moves the table while the stationary laser head reflects two beams off the retroreflector. The Doppler effect causes a phase shift of the signal that indicates the position of the table when the measurement is made. Any angular shift of the two reflected beams from the central target indicates pitch or yaw. The system is capable of making linear measurements up to 60 feet and angular measurements up to 30 feet.

Microsoft Windows-based software is used to collect measurement data. Compatible with most PCs and notebooks, the system requires an RS-232 port to the computer, but no special interface boards. Since the system automatically senses table movement, data collection is automatically triggered after a pre-defined interval as the table begins to move and stop.

Related Content

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read More5 Things CNC Operators Must Know About Sizing Adjustments

For CNC operators, sizing adjustment is an essential skill. Keep these points in mind when training new CNC users.

Read MoreHow to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)