Considering that Snap-on Specialty Tools’ core business is just what the name implies—manufacturing specialty tools—it’s somewhat ironic that haphazard tool management turned out to be the culprit behind rising costs and falling productivity a few years ago. However, according to Ed Deamer, manufacturing supervisor, this had become a significant problem by 2008.

The solution, however, turned out to be more elegant than Mr. Deamer had imagined. Developed by Winware (Marietta, Georgia), the Cribmaster inventory management system helped reduce costs and improve productivity by eliminating the practice of wasting tools to make tools.

Before Cribmaster, each supervisor at the Snap-on facility in Escondido, California was independently responsible for purchasing the cutting tool inventory needed in his or her particular area of operation. As a result, the company issued a constant flow of purchase orders, many of which were redundant. It was not uncommon, for example, for one supervisor to place an order on Monday and another supervisor to duplicate that order on Tuesday. Without a system in place to consolidate orders or track the quantity of ordered products, this frequent and redundant purchasing began to have a negative impact on the operation, Mr. Deamer says.

He points out that this impact went beyond simply spending too much on cutting tools. This haphazard approach to tool management resulted in surpluses of those that were used least often and shortages of those that were used most often. Additionally, the sheer quantity of purchase orders issued drove up the indirect costs associated with processing those orders. Seeking a solution, the manufacturer consulted with its long-term tooling supplier.

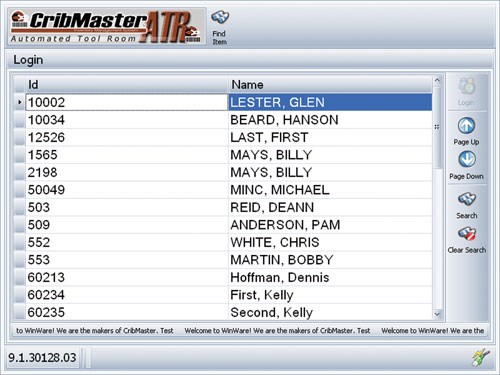

That company, D&D Tool Supply, recommended implementing a Cribmaster vending system to gain better control of tool usage, along with adapting newer cutting technology. The inventory management system, which is essentially an intelligent vending machine, is designed to be simple to operate. First, employees must authenticate themselves via one of various available methods, such as entering a personal identification number (PIN) or scanning a badge. At that point, the unit’s touchscreen displays images of available inventory. Once the desired item is selected, the helix inside the unit releases it. When that item is removed, Cribmaster software logs the transaction and updates the quantity available for that particular item. The software also issues alerts when inventory levels become critical to avoid stock-outs.

Bringing in new, more advanced cutting tools and using Cribmaster to manage them increased productivity by 7.89 percent within one year, Mr. Deamer says. Additionally, the reports generated by Cribmaster software enable the company to not only streamline inventory and reduce downtime, but also to track usage history by employee. For example, in one instance, machine shop supervisor Dustin Trent noticed that one particular employee had been using more inserts than usual. After a quick investigation, he discovered that the cause of the spike in use was a mechanical problem with one of the machines. Thanks to Cribmaster, this problem was quickly remedied before it became more costly.

Moreover, many of the benefits the company has realized from implementing Cribmaster go beyond features of the system itself. D&D Tool offers an extended services group with the sole responsibility of monitoring all functions related to its Cribmaster customers. Once Snap-on’s purchase orders are emailed using the systems’ auto-purchase feature, the service group takes responsibility for monitoring open orders and reorder points; creating reports; verifying that any excess tool or insert usage can be attributed to a spike in production; managing the receiving and stocking process; and other such services.

Since 2009, Snap-on has moved from Escondido to a nearby City of Industry plant. However, regardless of where the operation is located, the company is confident that managing the tools that make the tools will no longer be a problem.

.png;maxWidth=300;quality=90)