Rethinking Machine Tool Spindles

Through extensive research involving more than 4,000 individual tests, this company determined that unequal air pressure - caused by the location of ports around the circumference of a spindle's seals - creates adjacent zones of high and low pressure inside the seal.

Over the long term, spindles bear the brunt of punishment meted out by day-to-day machining forces. For metalworking professionals, spindle failures are among the most costly and disruptive events that occur in the course of daily operations. The proliferation of enclosed and guarded machines that incorporate high pressure coolant delivery systems exacerbates the difficult conditions to which spindles have traditionally been exposed.

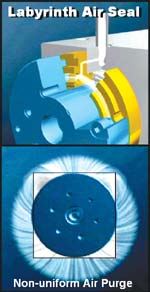

The conventional means of protecting precision spindle bearings from contamination is to continuously purge pressurized air through labyrinth-type bearing seals during operation. In the past, it has been assumed that, simply by maintaining sufficient air pressure through the spindle, this contamination would be prevented. The laws of physics, however, dictate some shortcomings to this approach that can lead to nagging failures, particularly under extremely demanding machining conditions.

North America's largest independent spindle builder, SETCO (Cincinnati, Ohio), made a decision in 1996 to address the problems of contamination and early failure. Through extensive research involving more than 4,000 individual tests, SETCO determined that unequal air pressure—caused by the location of ports around the circumference of a spindle's seals—creates adjacent zones of high and low pressure inside the seal. As a result, coolant—the primary cause of bearing failure—is driven from high-pressure to low-pressure zones. In effect, this phenomenon causes coolant to be sucked into the bearings. This can occur during machining or when the bearings cool down between machining operations. Under these conditions, increasing the air pressure cannot solve the problem. In fact, higher air pressure only makes the problem worse.

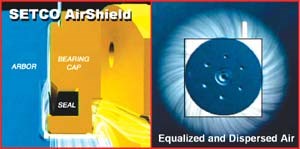

As a solution to this dilemma, SETCO developed the AirShield line of spindles. These products incorporate a proprietary, tangential air-purge system that equalizes pressure around the seal but does not inhibit bearing lubrication. Performance maps generated during the manufacturer's testing illustrate this pressure equalization. Tests revealed that internal pressures of the AirShield products varied within a maximum range of only 10 percent of the total pressure, compared to a typical 40-percent variation when standard labyrinth seals were tested.

The most common porting configurations for conventional, labyrinth-type seals are single-port, double-port (opposed 180 degrees) and six ports (equally spaced). Although the problem of non-uniform pressure distribution becomes less severe as the number of ports is increased, SETCO's testing demonstrated that significant pressure variations affect all types of conventionally ported spindle seals.

In real-world applications, the AirShield products have delivered impressive results. The manufacturer reports that, after more than 34,000 hours of continuous operation in a deep-hole drilling process that was conducted during a four-year period, not a single spindle failure has been reported. Additionally, the spindles' performance characteristics are unaffected, regardless of the particular duty cycle, direction of rotation or spindle attitude. Based on results from 23,000 spindles operated during the past 10 years, the company reports that its product has demonstrated a mean time between failure (MTBF) of more than 3 times greater than the value for conventional, labyrinth-seal units.

To showcase the capabilities of AirShield products and its entire line of spindles, slides and machining modules, SETCO actively pursues partnerships with machine tool builders around the world. The company is also the largest spindle rebuilder in the United States. Besides rebuilding spindles to original specifications, the company has the engineering capabilities to upgrade specifications and performance capabilities according to the customer's needs.

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)