Retrofit Enables High Speed Machining of Carbon Fiber

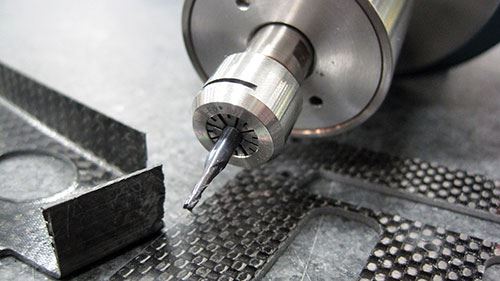

With the help of an air turbine spindle from Air Turbine Tools, Flying S was able to turn a small end mill at the speeds necessary to cut a bonded carbon fiber part for a UAV.

Most of the time, quality tooling combined with smart machine practices is enough for Flying S to competitively cut carbon components used in aerospace applications. However, when a new project required a small end mill to cut a bonded carbon fiber part, the company realized it couldn’t run at the speeds necessary for production without creating burrs. A twin-turbine air spindle from Air Turbine Tools provided the higher rpms needed to complete the high-

precision job.

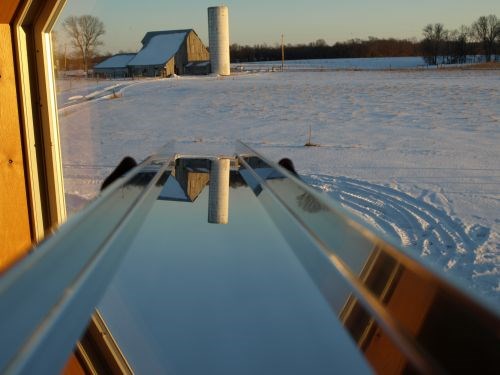

Ten years ago, Flying S began as a home-based design consultancy that expanded to a garage with a couple technicians fabricating prototypes for unmanned aerial vehicles (UAVs) and other aerospace and defense projects. As the company grew, owners David and Penny Shaw built a new 16,000-square-foot facility on their family farm in Palestine, Illinois to accommodate more manufacturing capacity. This past spring, an addition doubled the size of the facility to house an extensive machine shop that employs 30 people.

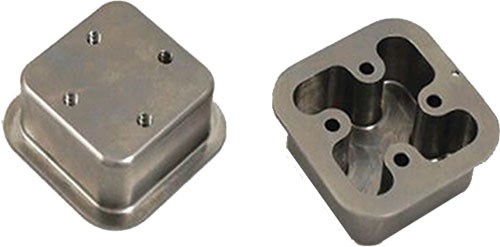

It was in this facility that Peter Bowman, who is in charge of part fabrication, encountered a critical machining problem. A project required the use of a 1/16-inch-diameter end mill to cut carbon fiber that had been bonded to a proprietary, hardened material. To complicate matters, the end mill needed to run at production speeds without creating burrs. Furthermore, when making test cuts, the company found that its fastest spindle was destroying the part during the cutting process. “Bottom line,” he says, “we couldn’t make the parts.”

With these issues fresh in mind, Mr. Bowman attended training at the Vincennes University Haas Technical Education Center (HTEC) in Vincennes, Indiana. There, he noticed an air-spindle attachment from Air Turbine Tools (Boca Raton, Florida) mounted to a Haas machine. The attachment turned out to be exactly what he was looking for. Not long after the training session, Flying S incorporated a 650X double turbine on the Haas VF-6 CNC machine in the back of its plant. “For a fairly economical price, we were able to take our versatile 7,500-rpm Haas and upgrade it to perform a very high-precision, intricate job at 40,000 rpm,” Mr. Bowman says.

The spindle attachment is powered by a patented turbine with an O-ring governor that increases airflow to maintain constant speed and torque as the cutting tool comes under load. According to the manufacturer, this enables the spindle to stay within 20 percent of its rated speed until reaching 80 percent of maximum power, even in corners and hard materials. Maintaining constantly high speed throughout the program cycle has enabled Flying S to cut the bonded carbon fiber part competitively. “Our carbon fiber and hardened steel parts project proved to be no problem with the governed high rpm,” Mr. Bowman says.

Another feature that has helped improve cycle time is the toolchanger mounting assembly (TMA). The spindle loads automatically from the CNC magazine into the turret and is fitted with a collar that connects to a block on the side of the main spindle. The auto changer assembly enables the spindle to be fully integrated in the program. According to Mr. Bowman, the toolchanging assembly enables the Haas CNC to load the 650X from the magazine and run completely unattended in full production. “The ability to integrate the high speed spindle is saving a huge amount of man hours on our jobs,” he says.

The direct-drive spindles also operate without brushes or gears. According to Air Turbine Tools, this enables the spindles to work reliably 24/7 with no duty cycle and low vibration. Compressed air circulates through the spindle body, cooling the ceramic bearings. This leads to increased precision and the reliability necessary to manufacture UAV parts.

While much of the carbon fiber Flying S trims is done on the Haas CNC, there is still a great need for hand work on its other UAV products. When the company purchased the 650X air spindle, it also invested in a 201SV air-turbine hand tool. The assembly technicians grew to love the quiet power of the hand tool, along with its lack of vibration and comfortable feel, Mrs. Shaw says. “While initially we balked at the cost of the tool compared to our economy pencil grinders, it only took replacing several of those cheap tools over the course of a year to see that getting the right tool was more important from the start,” she says. In fact, Mrs. Shaw says Flying S plans on ordering more.

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)