Rigid Spindle Extension Solves Deep Mold And Die Problems

In the past 15 years, there has been an increasing demand for stronger, but lighter, automotive and aerospace components. To save weight and increase structural integrity, many small subassemblies have been redesigned into a single integral part.

In the past 15 years, there has been an increasing demand for stronger, but lighter, automotive and aerospace components. To save weight and increase structural integrity, many small subassemblies have been redesigned into a single integral part.

Producing these parts, however, requires much larger and more complex molds and dies, which creates a problem for the companies that produce them how do you machine a 16-inch deep cavity that will only permit the use of a two-inch diameter tool?

That's the problem that faced Forge Die and Tool, a 75-man shop in Farmington, Michigan that produces forging dies and plastic injection molds for the automotive and aerospace industries. "We specialize in large parts," says Max Scott, vice-president of operations. "We do a lot of work for aerospace companies large aircraft wheels, wing struts, bulkheads. Also dies for automotive bumpers and fenders. These dies are deep and to make them, you have to have spindle extensions for the milling machines."

Forge Die and Tool experimented with various types of extensions, mostly designed in-house, but in every case ran into excessive vibration, resulting in broken carbide inserts and/or cutter bodies. "There were some jobs we wouldn't even attempt," says Mr. Scott. "Even with the ones we could do, we had to operate at reduced feeds and take very light cuts."

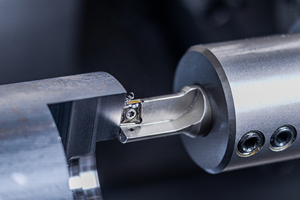

To solve the problem, the company turned to the Mold Masher series of spindle extensions produced by Harroun Enterprises, Inc., in Fenton, Michigan. The device is a newly patented system that incorporates a tapered shank tool coupling secured and released by the host machine's power draw bar.

"Now we can handle dies 14-, 16-, 18-inches deep," Mr. Scott says. "It's much easier, and we don't have to worry about line up and runout. Also, we can take heavy cuts, which is the big advantage of this system. Even in deep dies, it's common for us to take half-inch cuts at feeds of seven to ten inches per minute in FxT2 material, 38-42 Rc. Not only is machining a lot quicker, the operators have an easier job. They don't have to fight the vibration, the squealing and the noise they had before."

Forge Die and Tool works to pretty tight tolerances, which the Mold Masher extensions have no trouble handling even in deep cavities. "With forging dies, we work to within 0.005-inch," Mr. Scott says. "Automotive body dies are usually tighter, on the order to 0.002- to 0.003-inch."

As for surface finish, Mr. Scott says that you cannot expect as fine of a finish using a 14-inch extension as you would get from a two-inch long cutter. "But, the difference in finish is really minimal and the result meets all our requirements."

Hugh Harroun, who developed the Mold Masher spindle extension, says, "When collet systems are applied to spindle extensions, they often employ an external nut to tighten the collet. This causes clearance interference along cavity walls, where a high clearance profile is essential to mold and die machining."

Mr. Harroun adds that some collet systems, to avoid clearance interference, use an internal draw bolt to tighten the collet, but this requires the dismount of the entire spindle extension merely to change the tool.

The Mold Masher system uses a 20-degree tapered shank tool coupling which permits the use of the host machine's power draw bar. This results in several significant benefits.

For one thing, the tapered shank permits tooling heads to be manufactured to qualified lengths, eliminating the need for redundant Z-axis pickups. For another, when the operator wishes to inspect the cutting tool for wear and make a change, he can have a second tool body of exactly the same length available and, dropping the worn tool via the power draw bar, can quickly insert a fresh one.

The Mold Masher coupling has a 90 percent surface-to-surface contact which greatly increases its rigidity. In addition, Mr. Harroun says, "A 50 taper draw bar typically has 3500 lbs of pulling power. This serves as a dynamic stiffener to the spindle extension, making possible heavy cuts with much less vibration."

Mr. Scott points out that the Harroun system permits tool changing in about ten seconds compared to the half-hour or more previously required. "If a machine has eight tool changes a day," he says, "that adds up to two hours per shift saved every day in changing tools."

Forge Die and Tool has about ten of the Harroun spindle extensions in various lengths. Asked what they have contributed to his company, Mr. Scott says, "I can't say anything bad about them. They've been real assets for us. Anything you get that does the job quicker and holds tight tolerances is good for our business." MMS

Related Content

Haimer USA Models a Streamlined Toolroom

Haimer USA is celebrating its 20th anniversary with a live demonstration of its digital toolroom. Find out more past the aluminum panther.

Read MoreJergens Pull Studs Enable Quick Changeovers

SP140 and K02 pull studs offer quick-change solutions for vise or gripper jaws, electronic component manufacturing, packaging machines, medical technology and automation.

Read MoreAll-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreCeratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)