Sensors Automate Grinding, Dressing Wheel Positioning

By listening for slight changes in sound, acoustic emission sensors enable grinding machine owners to automate their wheel positioning and dressing processes with precision and accuracy.

In the past, positioning grinding wheels often involved listening for the moment of contact with the workpiece. That’s still the case today, but with one notable difference: Machinists no longer have to rely on the human ear alone. Rather, many employ acoustic emission (AE) sensors that can detect when even a single grain on a grinding wheel contacts the surface. Drake Manufacturing Services Co., a manufacturer of precision grinding machines, credits these sensors for not only automating wheel positioning and dressing, but also significantly improving the precision of those processes.

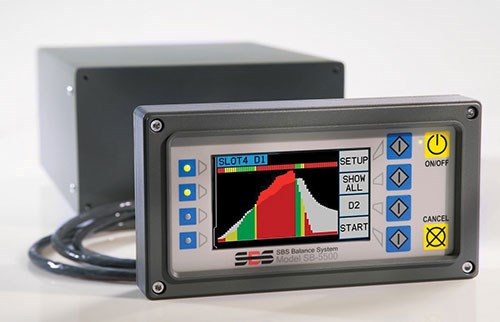

The Warren, Ohio-based company designs, builds and services CNC thread and gear grinding machines, many of which incorporate AE sensors for wheel and dresser positioning alike. The company’s system of choice is the SBS SB-5500-G from Schmitt Industries of Portland, Oregon. The SB-5500-G can accept inputs from three types of sensors: bolt-on, in-spindle and remote mounting. It outputs acoustic readings in dyne units, both graphically on its panel and electronically via USB and analog interfaces, which connect directly to PLCs and CNC machines. The sensor supports eight selectable AE frequency bands, ranging from 50 kHz to 950 kHz, and two separate channels enable independent configuration modes using one or two sensors.

Each grinding process requires a learn cycle to “teach” the sensor a particular process. First, the sensor listens for background noise. Then, the grinding wheel touches the workpiece, or the dressing wheel touches the grinding wheel, and the machine operator or the attached PLC or CNC learns that sound. For example, during wheel dressing, a specific signature pattern on the display screen of the SB-5500-G indicates the wheel is being profiled correctly. This technology enables users to automate the positioning of the wheel relative to the workpiece or the position of the dressing unit relative to the wheel, thereby reducing waste and producing a higher quality product.

The sensors provide accuracy improvements as well. Before automated AE sensing technology was commercially available, a positioning tolerance of 0.002 inch was considered very tight. Now, 20 to 40 microns per touch is considered a realistic target for grinding machines. “Using AE enables us to avoid the uncertainty as to whether we’re dressing a wheel correctly, and it saves a lot of time and wheel in the process,” says Stig Mowatt-Larssen, Drake’s R&D manager.

Among the machines Drake produces are grinders that use AE technology to condition cubic boron nitride (CBN) grinding wheels with diamond dressing rolls. “To true the grinding wheel, we want to take as little as 1 micron off each side,” Mr. Mowatt-Larssen says. “The feedback from an acoustic emission sensor makes this possible.”

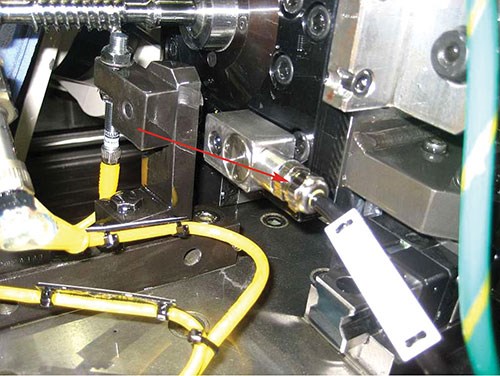

Drake also uses AE technology on a machine used to finish grind a worm gear shaft for an automotive steering application. In this case, a tailstock-mounted SBS SB-4240 bolt-on sensor picks up the sound produced when the grinding wheel first contacts the side of a screw thread that has already been roughly cut into the part. From these positions, the machine calculates the center of the thread and the grinding start position. The result is a grinding process that removes equal material from both sides of the precut thread.

Mark Astor, Schmitt applications engineer, cites a number of other benefits of AE sensors. As long as a grinder’s wheel positioning system responds quickly (within milliseconds), AE technology can be used to further improve processing speed by reducing “air grinding” as well as alert operators of wheel crash conditions caused by improper workpiece positioning. In that same vein, AE technology can help with problem diagnostics. “If there’s a breakdown in the wheel, we can see immediately where the problem is, which would otherwise require maybe a half hour to study,” Mr. Mowatt-Larssen says.

AE also helps adjust for the effects of temperature changes on machine elements, Mr. Astor says. For example, when a machine sits idle overnight, its spindles cool and the orientation of the dresser roll to the wheel can change. By touching one side of the diamond wheel to the dressing roll and then touching the other side, the machine can find the center of the wheel. This enables the machine to dress off the least amount of material to get the wheel back in shape, he says.

To provide precision grinding machines, Drake uses AE techniques to save time and produce a more accurate grinding profile. Mr. Astor says it is quicker than offline or manual-position sensing, and it produces more repeatable results than any of the manual modes.

Drake plans to upgrade its AE sensor soon by installing Schmitt’s SBS ExactDress software, which will further automate the dressing process, Mr. Mowatt-Larssen says. “The SBS products are not just stand-alone instruments. They are designed to integrate easily with our control systems,” he says.

Related Content

Buying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreGrinding Wheel Safety: Respect The Maximum Speed

One potential source of serious injury in grinding comes from an oversight that is easy to make: operating the wheel in an over-speed condition.

Read MoreChoosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read MoreChoosing The Right Grinding Wheel

Understanding grinding wheel fundamentals will help you choose the right wheel for the job.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)