Show Me the Fixtures

Innovative workholding devices intrigue me. If you’ve developed what you consider to be a nifty workholding solution of your own, I’d like to see it.

I appreciate that we cover a range of machining topics in this magazine and, in doing so, get to visit a variety of shops. Regardless of the article topic, however, I’m always curious to see how shops fixture parts for machining.

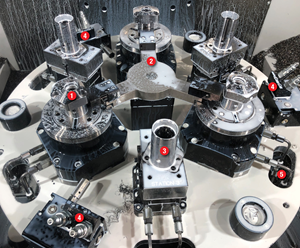

It’s interesting to see unique workholding devices a clever person has created for odd parts. But it’s just as neat to see custom devices that provide a more effective way to secure parts with straightforward geometries. Mike Brown, the vice president of manufacturing at E.F. Bavis, has developed a number of interesting job-specific fixtures over the years for both scenarios. I got to see some of those when I met with him to develop the story that starts on page 88. Plus, each of his three CNC toolroom mills has a pin in the center of the table onto which the fixtures are located. This speeds changeovers by eliminating the need to indicate fixtures before starting a job.

One of the niftiest workholding solutions I’ve come across is nicknamed the “lollipop” and was developed by Harmonic Drive LLC. The company needed to secure small, bell-shaped workpieces called flexsplines for turning, spline machining and OD inspection. The part, which begins as a 15-5PH stainless steel forging, first has its ID turned. This creates a wall thickness of approximately 0.06 inch. A final wall thickness of 0.01 inch is attained through OD turning. Because of the part’s shape and extremely thin wall thickness at this stage, it can’t be clamped in a lathe’s chuck. The thin walls would not provide adequate support during the turning operation.

To solve its workholding dilemma, the company decided to machine an arbor from a Sandvik Capto boring bar blank onto which the flexspline can be mounted. However, because of the part’s bell-like internal profile, voids exist between the arbor and inner surface of the workpiece. To fill these voids, the shop pours a low-melt-temperature alloy through a bore down the center of the arbor. Once the alloy fills the voids and solidifies, the part and arbor bond together to become one piece. Therefore, the alloy provides the internal wall support required to turn the part’s OD to the desired wall thickness. After all machining and inspection operations are completed, the alloy is melted away and the completed flexspline is removed from the arbor.

Of course, many job shops approach new projects expecting to use a vise. This is understandable, because these universal devices enable them to accommodate the wide range of parts they encounter. So while a vise might not be the ideal workholding solution, shops justify them because it can be impractical, too costly or time consuming to engineer and make custom fixtures for a job they may never see again.

Conversely, other shops have found value in making the investment to create custom workholding devices. In fact, some have gone on to turn their ideas into marketable products. If you’ve developed such a workholding solution and would like to crow about it, send me a photo and brief description. If I receive enough examples, I’ll share them with our readers.

Related Content

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)