Software Leads To Integration In The Job Shop

Jim Andries of Stremel Manufacturing had a vision of his company's software and employees working together. After several years of piecemeal software purchases, Mr. Andries' vision turned into a true need for shop integration.

Jim Andries of Stremel Manufacturing (Minneapolis, Minnesota) had a vision of his company's software and employees working together. After several years of piecemeal software purchases, Mr. Andries' vision turned into a true need for shop integration.

When Stremel required a CAD/CAM program for its fab shop, the company turned to Merry Mechanization (Englewood, Florida). Later, Vantage, a shop control package from DCD (now Epicor of St. Louis Park, Minnesota), was brought in. Then followed a TekSoft (Scottsdale, Arizona) design and manufacturing package, as well as Machine Shop Estimating from Micro Estimating Systems (New Berlin, Wisconsin), SolidWorks from SolidWorks (Concord, Massachusetts), and more recently, CAMWorks, a TekSoft CAM program that operates within SolidWorks.

The addition of Machine Shop Estimating (MSE) brought not only a more accurate method of estimating, but it showed that integration was a realistic goal. MSE was a tool that helped ensure accurate job estimates, but more importantly, a successful, transparent interface existed between Machine Shop Estimating's speeds and feeds libraries and Mr. Andries' two TekSoft programs. Still, the software picture at Stremel as a whole left Mr. Andries seeking more. Now Mr. Andries had more accurate estimates, but he had to find a way to avoid manually reentering them into Vantage.

Help for Mr. Andries to improve his software compatibility came from distributor Kevin Bork of CAM Solutions (Bloomington, Minnesota). Mr. Bork was familiar with each program and recognized that the overlapping capabilities created workload redundancies at Stremel. Understanding the value of the integrated concept proposed, Mr. Bork got on board the integration effort.

Mr. Andries and Mr. Bork began contacting vendors about integration. In addition to working with Stremel, some software developers began working among themselves to improve their information transfer. Mr. Bork developed the crucial link himself, between Vantage and MSE. With those systems linked now, there have been fewer errors and less redundancy.

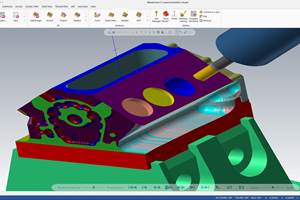

"Our customers send their native files directly to us over our phone lines. This (SolidWorks) creates a 3D picture, from which CAMWorks will automatically generate a tool path," Mr. Andries says.

Because the two TekSoft CAD/CAM programs in place at Stremel have interfaces to the machine speeds and feeds libraries in Machine Shop Estimating, the tool information used on the shop floor and in the drawings for parts is the same information the estimator uses. This reduces variances. Having fewer libraries also reduces clerical errors and redundant data entry efforts. The libraries are updated and corrected once, throughout the entire system. It also helps ensure that tool default parameters used to generate tool paths from blueprints submitted by customers are set up properly.

The latest phase of the integration plan is a DNC program. It links the shop's machining center programs and setup sheets with Vantage's Document Management capability without the expensive memory upgrades which would otherwise have been required to store the shop's existing part programs. Now the machining centers are linked to a server which downloads data to all the workcenters simultaneously, allowing operators to view part programs and print out setup sheets from any shop computer. The new system provides the shop employees the flexibility and access to information they need, but it also protects the information by restricting Gcode file editing capability via logon names.

"Since we can tie the DNC system with Vantage, operators will gain access to inspection reports, setup sheets, tool lists, diagrams describing setup—even digital photographs of the setup, or a video," Mr. Andries says.

Stremel's commitment to integrated shop technology has not been inexpensive, but Mr. Andries thinks it has given him an advantage over his competitors.

Related Content

6 Steps to Take Before Creating a CNC Program

Any time saved by skipping preparation for programming can be easily lost when the program makes it to the machine. Follow these steps to ensure success.

Read MoreHow to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

Read MoreCAD/CAM System Requirements: An Overview

CAD/CAM programs are among the most demanding kinds of computer software. Smooth operation requires careful consideration of computer specifications.

Read MoreWhen Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More