Steady-Rest Fixture Fixes Runout At The Ends

A shop developed this simple solution for turning long shafts that have straightness error. A fixture holds the bowed shaft out-of-round in the steady rest so that the two ends can still turn concentrically.

A little bit of straightness error can translate to significant runout error between the two ends of a long shaft. This runout error creates the potential for a variety of problems when the two ends are turned. And if the part needs a steady rest, then this support in the middle may arguably make those problems worse.

Consider a long shaft requiring concentric turned surfaces at either end. The part will be held on-center at the chuck and in the steady rest, but at the remaining end—the end being turned—the part will spin out-of-round. One problem with this is the potential for chatter, which may compel the shop to slow to a minimal speed. Another, even greater problem is that the turning may not be accurate. When the part is flipped to machine the second end, the centerlines of the two turned ends may differ to an unacceptable degree.

Given these runout-related problems—and given a shaft that doesn’t need to be precisely straight, just turned concentrically at the ends—the turning process would be better served if the shaft could rotate along a common centerline at the two ends, while somehow being allowed to rotate out-of-round in the middle. In other words, turning would work more effectively if the shaft could be supported out-of-round in the steady rest.

That was the thinking of Bruce Rancilio, a machine shop supervisor at the CAI Industries plant in West Frankfort, Illinois. Barry Milton, a machinist at this plant, recently contacted to describe a solution devised by Mr. Rancilio to meet the challenge of turning precise bearing fit surfaces on long shafts. For this work, the shop uses a fixture inside the steady rest to support the shaft away from the centerline of the lathe’s rotation.

CAI Industries makes heavy equipment for coal mining. Long shafts requiring concentric bearing fit surfaces at either end are common workpieces here. The shop routinely machines shafts as long as 10 feet. For these shafts, the shop uses Mr. Rancilio’s fixture both to turn without chatter and to achieve concentric turning when the shaft is not straight.

To begin the setup using the fixture, the shaft is centered in the chuck at one end while it is temporarily centered at the other end by using the steady rest to support it there. During this step, the steady rest should locate in the middle of the length to be machined so that any runout error in this region is split between the two sides of turned area. If a 12-inch bearing fit length is needed, for example, then the steady rest should support the part 6 inches from the end. Center drilling is performed while the steady rest is supporting the free end in this way.

The part is then flipped. The other end is center-drilled the same way, with the steady rest again supporting the part 6 inches from the end.

Now the shaft can be held so that the two ends are concentric. The fixture—which Mr. Rancilio calls a “steady rest centering tube,” or SRCT—takes care of the bow in the shaft’s middle. The fixture itself is concentric with the axis of rotation, but the screws that hold the shaft support the work away from this centerline.

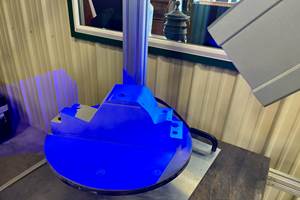

The SRCT is not a product that can be purchased. Instead it is simply a solution that other shops can replicate. Mr. Rancilio says an SRCT can be fabricated from any length and diameter of tube that has been OD-turned along its full length. He advises that the tube should have a minimum wall thickness of 3/8 inch. Four holes at each end are drilled and tapped (see photo), with adjusting screws and lock nuts added. The SRCT can then be used anywhere the steady rest might be used, at any position along the turned workpiece’s length.

Another important application of this device relates to shafts that don’t have a circular cross-section, such as square or hexagonal shafts. Normally these shafts couldn’t roll in a steady rest, he notes, but the fixture changes this. Bearing fit surfaces can therefore be turned on long, non-round shafts just as if they were round ones. On long square shafts, the CAI Industries plant has used the steady rest fixture to do exactly this.

Related Content

Moving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreRead Next

Sometimes the Trickiest Part of CNC Machining Is Holding the Part

Finding a way to fixture contoured marine propellors proved to be this shop’s biggest challenge in developing an effective automated machining cell.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)