Strategy-Based Machining

Whereas some Knowledge-Based Machining systems capture how a part is machined, or (on a higher level) capture the rules that govern how a part is machined, this company's Strategy Manager seeks to capture the logic behind the decisions to machine a part one way or another.

Many CAM software packages now include some sort of knowledge-based machining (KBM) capability. The idea is to capture how a part is machined and apply the same proven process to similar parts that follow. KBM streamlines and automates NC programming steps to make the process more efficient and more effective.

Pathtrace Systems Inc. has introduced a new twist to this concept in its EdgeCAM Strategy Manager, a feature incorporated in version 7.0 of the company’s flagship off-line programming software. Whereas some KBM systems capture how a part is machined, or (on a higher level) capture the rules that govern how a part is machined, EdgeCAM Strategy Manager seeks to capture the logic behind the decisions to machine a part one way or another. Designed exclusively for use with solid CAD files, this feature supports product models created by SolidWorks, Inventor, SolidEdge, Pro/Engineer and other Parasolid-based CAD systems.

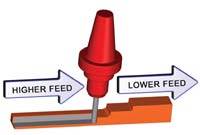

The logic of a machining strategy is represented by a flow chart that shows what options were available to the programmer when confronted with various workpiece features. The options embedded in the flow chart are based on preferences predetermined by the shop’s production team, methods department or top programmer. These options are linked to the tooling database and to the part feature. Thus, when attributes of the part feature are changed in the underlying solid model, the correct tools and the appropriate feed/speed values are automatically incorporated into the revised flow chart.

For example, if a hole size changes, the system recognizes whether or not an alternative process applies. Should the hole diameter go over a certain limit, thread milling may replace tapping, with a new set of options appearing to set parameters for thread milling. Should hole depth exceed a certain limit, a pilot hole may be required, with options appearing to establish the pilot hole routine. Similarly, adding a counterbore or chamfering feature would modify the flow chart accordingly.

Of course, expert programmers do not always “follow the rules,” so the programmer can override the rule-based decisions to pursue a different strategy. However, the flow chart lets the programmer assess the impact of this exception on subsequent machining steps, which may need to be reconsidered in light of the changes.

The flow chart approach allows users to build in any decision necessary to machine the workpiece appropriately, keeping the number of strategies to an absolute minimum, developers say. A programmer may develop different strategies for unattended or overnight operation, but not usually for different styles of workpieces. This ensures that the correct strategy will be applied consistently.

Because these strategies are managed in a graphical format, the programmer has an easier time keeping track of the overall process plan as it is being developed. Programmers do not need to know Visual Basic or some other high level computer scripting language to create or modify these machining strategies.

The initial release of the EdgeCAM Strategy Manager covers holemaking operations. Additional machining operations are being developed and will be released after testing.

Pathtrace’s new concept for KBM underscores a key point about automating the NC programming process. This thrust is not likely to diminish the need for programming skills but to boost the productivity of the existing expert programmer and to enhance the skills of less experienced programmers.

Read Next

Getting To Know Knowledge-Based Machining

The term refers to different levels of automation that CAM software developers are building into their NC programming software.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)