Supertec Mini Genie Cylindrical Grinder Removes More Stock

IMTS Spark: Supertec Machinery’s Mini Genie CNC cylindrical grinder is designed for shops with limited floor space

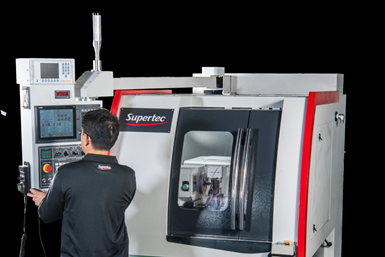

Supertec Machinery has introduced the Mini Genie CNC cylindrical grinder to the North American market. The machine is designed for shops with limited floor space, with a total footprint of 78" × 78" (43 sq. ft.).

The Mini Genie has a grinding capacity of 9" diameter and 8" between centers, with a work load capacity of 44 lbs. between centers and 11 lbs. chucked. The wheelhead uses an NN contact taper needle roller bearing spindle with a 20" × 2" grinding wheel and 10 hp spindle motor, which allows for greater stock removal resulting in reduced cycle times. It can handle a range of materials like cast iron, Inconel, carbide and chrome.

The workhead (MT3 with MT4 optional) has an NN contact taper needle roller bearing spindle with a servomotor drive for maximum torque. The workhead has infinitely programmable spindle speeds from zero to 600 rpm.

The Mitsubishi M80 control, with Supertec’s I-Grind conversational shop floor language the grinder is designed to be easy to learn and program. The graphic display screen allows the operator to review the part program prior to grinding and make adjustments. The Mitsubishi M80 (and optional FANUC Oi-TF) control can be interfaced to a variety of measurement systems, such as touch probes and automatic sizing devises, as well as robotic and gantry-style loading systems.

The Mini Gene comes in two styles, a plunge model with the wheelhead set at 90 degrees, and an anglehead model with the wheehead set at 20 degrees. The anglehead is ideal for faster stock removal and better surface finish on face and shoulder grinding applications. The machines use a Heidenhain 0.000002" linear scale for improved accuracy and repeatability, enabling users to attain tolerances of 0.0001" or better, according to the company. Both machine axes use linear guideways for smoother, more accurate movement.

Other features include a full enclosure, infinitely variable workhead, coolant system with paper filter and magnetic separator, and a taper-adjustable tailstock.

.png;maxWidth=300;quality=90)