Surface Texturing with Laser Ablation

Much of a product’s appeal to the consumer has to do with its look and feel—literally, the texture of its visible surface.

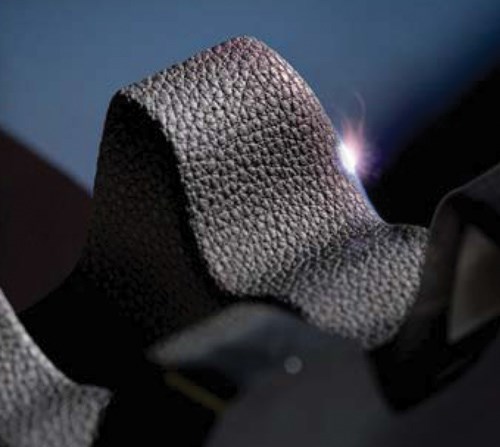

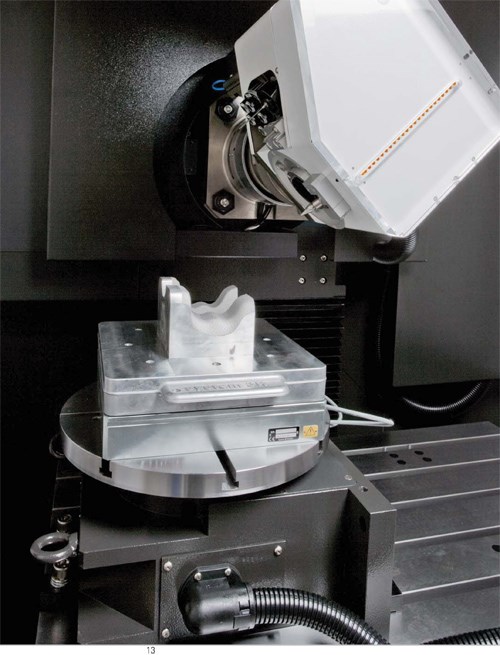

Much of a product’s appeal to the consumer has to do with its look and feel—literally, the texture of its visible surface. The pattern of tooled leather, the weave of a rich fabric or the grain of weathered wood pleases the eye and gratifies the touch. Reproducing such textures on metal workpieces is one of the primary applications for a line of laser-powered machine tools from GF AgieCharmilles (Lincolnshire, Illinois). The three- and five-axis models in this line use a high-powered laser beam that impinges on the workpiece surface under high speed computer control to remove material by ablation, thus creating virtually any surface texture that can be digitized. Ablation can be described as a method to melt and vaporize a workpiece material with high heat.

In addition to texturing, this process can be used to engrave, mark, label or render a microstructure on a surface in 2 or 3D. According to the company, this process can be applied to aluminum, copper, steel, graphite, carbide, brass, ceramics and other materials. Laser ablation is said to be more flexible, predictable and environmentally benign than acid etching or other conventional surface treatment.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)