Taking Spindle Health Seriously

Minimizing machine downtime became all the more important as this shop began targeting higher-production automotive work. To that end, it is in the early stages of implementing predictive spindle monitoring technology to head off problems that could take out key machines for extended periods of time.

Millennium Machining wasn’t always a mid-volume shop that primarily serves the automotive and heavy-truck industries. The 107-year-old business, formerly Hauser Company, was effectively a contract shop before Millennium purchased the company in September of 2004.

The shop’s president, Gus Ploss, says he decided to target higher-volume work after the acquisition in an attempt to push Millennium up the automotive supply chain. That’s happened. Over the past six years, the Macedon, New York company has grown to become a Tier-Two supplier to manufacturers such as Magna Powertrain, Detroit Diesel, Borg Warner and Allison Transmission. It also provides machined parts to its sister company, Millennium Industries, in addition to various other customers.

Of course, such a fundamental change of strategy (the former contract shop now targets jobs ranging from 20,000 to 120,000 parts per year) meant changes were needed to maximize throughput on the shop floor. To that end, cells are now more prevalent in Millennium’s 110,000-square-foot facility. Machines are grouped for specific jobs to limit work-in-process and part movement throughout the shop.

The type of equipment used is changing, too. Newer dual-pallet HMCs, including two NH 4000s from DMG/Mori Seiki and a pair of Doosan HP 4000s, have high-pressure, through-spindle coolant delivery. They also offer higher spindle speeds (up to 15,000 rpm) versus the shop’s other HMCs and VMCs, and they are run very close to their top speeds. Higher spindle speeds, combined with advanced cutters, enable faster cycle times for the primarily aluminum parts that flow through the shop. Meanwhile, coolant delivered through tools at 1,000 psi provides the effective chip removal needed with increased material removal rates.

The shop also places greater emphasis on preventive maintenance these days to optimize equipment reliability and longevity. Its preventive maintenance efforts are more structured and detailed, with printed procedures located at every work station listing clear instructions for all scheduled maintenance operations. The shop owns its own Renishaw ballbar, too, and performs routine ballbar tests on its machines to detect positioning errors noticeable only when a machine is in motion. In addition, an OTT-Jakob drawbar force gage is periodically used to determine each machine’s drawbar pulling force on toolholders, which can decrease over time and lead to problems.

Even with dutiful preventive maintenance and periodic machine diagnostic checks, however, major problems such as spindle failure have occurred at Millennium. A few years ago, in fact, the shop lost two spindles in one day on machines that were running a valve body job requiring 40,000 units per month. This big production hit prompted Millennium to become a test site for a new remote spindle monitoring technology designed to predict spindle problems before they become problematic. The Web-based system, which leaves spindle vibration analysis to specialists outside the shop, has already demonstrated its value on one occasion by detecting an abnormal vibration signature caused by a drawbar’s lower-than-normal toolholder retention force.

Predicting Spindle Issues

Millennium has 24 HMCs, 13 VMCs and a number of CNC lathes under its roof. Some of its machines date to the late 1990s/early 2000s, although a good portion of them have been upgraded with newer controls and spindles. GTI Spindle, located in Manchester, New Hampshire, handled many of the shop’s spindle upgrades and rebuilds. Through this relationship, Mr. Ploss learned that GTI had been working with InCheck Technologies (Northbrook, Illinois) to develop the InSite remote condition monitoring system for machine tools. He agreed to install the system on one of the shop’s new Mori Seiki HMCs to see how such a predictive tool might bolster his shop’s preventive maintenance efforts.

The spindle monitoring system consists of off-the-shelf sensors and common computer equipment. A temperature sensor and accelerometer (for vibration detection) attach to a machine’s spindle. Those sensors are wired to a compact data acquisition box mounted atop the machine that delivers data via Ethernet to a router. The sensor data is delivered over the Internet to a remote server managed by GTI. That means Millennium has no software to install or server to maintain.

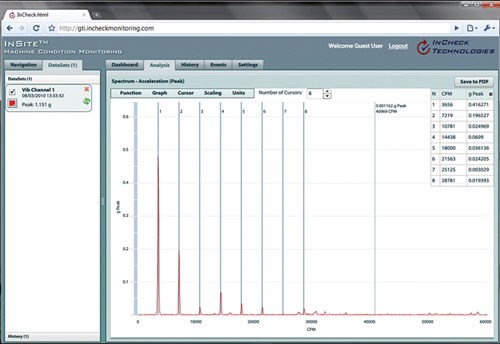

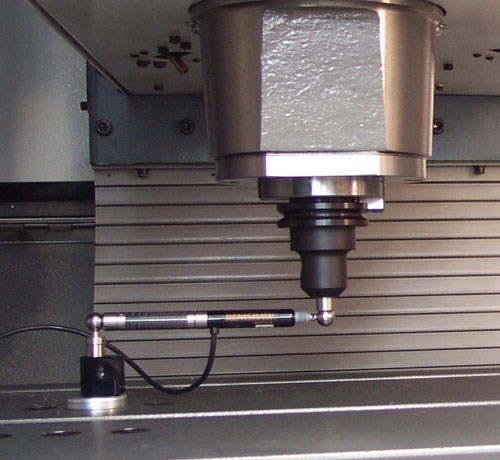

During system installation and setup by GTI, a spindle analyzer is used to make sure the spindle to be monitored is fundamentally sound. Next, upper warning and alarm limits for specific vibration signatures are determined based on the type of machine being monitored (mill, lathe, grinding machine, etc.). Limits are also set for temperature, because a higher-than-normal spindle bearing temperature can be an indication that the bearing may soon fail.

The system’s remote, Web-based functionality offers the shop a few advantages. For instance, no one at Millennium has to be an expert in spindle vibration analysis. When a warning or alarm level is reached, the system notifies GTI of the situation via e-mail, enabling a vibration specialist to review the data from the machine in question simply by accessing the Internet and logging on to the system. The specialist can then suggest possible causes of the problem so maintenance personnel at the shop can zero in on the issue and quickly remedy the situation. Specific problems might include worn bearings, unbalanced tools or low drawbar force.

In fact, the system recently detected a vibration signature that indicated a mechanical looseness problem within the HMC at Millennium. GTI suggested that shop personnel perform standard machine component checks, and it was determined that the drawbar retention force was one-third of what it should have been. The shop was able to pull the drawbar, change the Belleville washers and reinstall the drawbar. This process took just 4 hours. If left undetected, however, the spindle could have become damaged and would have required rebuilding. Removing, repairing and replacing the spindle would have taken one week.

The spindle monitoring system provides trending capabilities, too. For instance, it’s possible to track vibration signatures for bearings to precisely determine when they will fail. That way, parts can be ordered ahead of time and machine repair can be scheduled during a convenient period, ideally when the machine isn’t running production. Other capabilities include overlapping readings from one day to another to track changes, switching between types of graphs, taking measurements of graphs and changing alarm settings remotely. In this way, a Web browser functions like a dedicated, on-site analyzer, providing more than just a means to view a snapshot of critical machine data.

Predictability for Unpredictable Times

Mr. Ploss is pleased with the early results of the spindle monitoring technology, and will likely soon install additional monitoring systems on other key machines. He notes that the volatility in the U.S. automotive industry, largely based on quick adaptation to changing market demands, leads to drastic swings in part production volumes. Sometimes, the new production requirements are a great deal over and above what a shop like his might have previously been producing. For Millennium, that might mean extended stretches of 24/7 production, which is a good problem to have. But it’s also the reason why the shop will continue to look to preventive and predictive technologies to minimize machine breakdowns and downtime.

Related Content

Understanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.

Read MoreChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreChoosing Your Carbide Grade: A Guide

Without an international standard for designating carbide grades or application ranges, users must rely on relative judgments and background knowledge for success.

Read More10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

Read MoreRead Next

Video: Remote Spindle Vibration Analysis Explained

A new remote spindle monitoring technology offers a way to predict spindle issues before they become major problems that adversely affect production.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More.jpg;maxWidth=970;quality=90)

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)