The Appeal Of Peel Milling

Milling with high axial depth of cut and low radial depth of cut can offer an effective way to achieve high metal-removal rates in difficult materials.

Today, machine tools and cutting tools can both do more. With sophisticated controls, modern machine tools are capable of higher spindle speeds and feed rates. To take full advantage of these capabilities, smaller cutting tools have been developed that perform a number of operations in a single setup, including square-shoulder milling, contouring, slotting, plunging and both circular and helical interpolation. An example of such a tool, an inserted end mill available as small as 0.375 inch, is shown on the facing page. The combination of tooling such as this and modern machine capability allows users to embrace new methodologies. One methodology that deserves consideration is peel milling, which may offer a way for shops to overcome the challenges of slotting in difficult materials.

Peel milling is not a new process, but the modern version of it is. A decade ago, peel milling could be used only for either a finishing or a roughing pass. Doing both required two tools because of limitations in both the tooling and the machine. Continued advancements have given way to today’s peel milling operations, which allow roughing and finishing passes to occur at the same time.

Peel milling involves a large axial depth of cut—up to the cutter maximum—combined with a small radial engagement of 5 to 10 percent of the tool diameter. This combination results in an overall decrease in cutting forces, particularly radial forces. At the same time, both feed rate and speed can be increased. The benefits of machining this way include greater stability, more precise machining and faster metal removal. Additionally, peel milling offers the potential to eliminate secondary operations because the small radial engagement and light cutting forces produce such a good finish.

Light cutting forces also promote longer and more predictable tool life. Reduced radial contact between the tool and workpiece also contributes to prolonged tool life, because the cutting tool has less time to heat up and more time to cool down with each revolution. The potential value of this increased life is particularly significant when one considers that the tool used to do peel milling can go on to perform a variety of additional machining operations.

Trochoidal Peel Milling

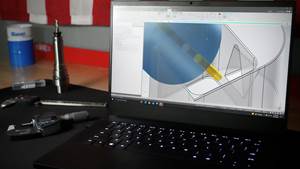

One variety of peel milling, called the trochoidal method, uses a series of overlapping circular cutting paths in the X-Y plane, with no machine rest, to effectively side-machine a slot at full depth (see illustration). The method was originally developed to address the demands of hardened and difficult materials.

Machining this way does place high demands on the cutting tool in terms of rigidity, geometry, and life. Though radial engagement is relatively low with this method, the cutter is still fully engaged and can be subject to deflection and vibration, particularly in more difficult materials and applications with long overhang. Only strong and rigid cutter bodies can be used, and stable process conditions are required. One other requirement is a tool with a free cutting geometry. With some inserted end mills providing these features even in relatively small tool diameters (Seco’s Helical Nano Turbo is an example), a single tool can produce a slot ranging from slightly larger than its diameter to several times its diameter. Such tools can deliver a high metal-removal rate combined with the economy, flexibility and freedom from the need to regrind tools that comes from the use of indexable inserts.

This milling method is effective for industries such as die/mold, in which older machining techniques required a series of back-and-forth movements. At slower speeds and with numerous passes, removing material from a cavity or pocket was time consuming. With the trochoidal peel milling style, operators can follow the contour of the component with increased cutting data, in many cases dramatically reducing the number of passes and the overall machine cycle time. What used to be a slow process—or one accomplished only by more expensive solid carbide end mills—is now accomplished in less time and with better results using indexables. Shops thinking about slowing down or lightening up should investigate straight or trochoidal peel milling to see whether there might be more productivity to be won.

About the author: Jay Verellen is milling product manager for Seco Tools, Inc., Warren, Michigan.

Related Content

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Read MoreFive-Axis Changes Weldments Into Monolithic One-Piece Parts

Moving from welding to five-axis machining enabled Barbco to redesign its weldments as monolithic one-piece parts with improved strength and repeatability.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreHow to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreRead Next

Practical Tips For High Speed Machining Of Dies And Molds

In die/mold work, the programmer can make the HSM process dramatically more effective. Here are some tips.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)