The Many Ways Ford Benefits from MQL

Clean machining using minimum quantity lubrication has allowed Ford’s Van Dyke transmission plant to become fundamentally more efficient and effective at manufacturing six-speed automatic transmissions.

Ford’s Van Dyke transmission plant implemented minimum quantity lubrication (MQL) for the same primary reasons other big manufacturers have done it. MQL lowers machining costs by eliminating not only the large volume of coolant used in conventional wet operations, but also all the ancillary equipment and electrical power necessary to maintain a big, central coolant system. MQL also creates a cleaner, safer manufacturing environment, which is beneficial to the health of both the equipment used on the shop floor and the employees who work there.

I suspect, though, that the Sterling Heights, Michigan plant initially didn’t realize how changing the way a cutting tool and workpiece are cooled and lubricated during machining would have such an impactful, trickle-down effect on its large-scale manufacturing process beyond the advantages just mentioned. Switching to MQL to machine three types of aluminum components for the company’s 6F line of front-wheel-drive transmissions has ultimately boosted the plant’s flexibility and efficiency, allowing it to more quickly adapt to today’s rapidly changing market demands for different types of vehicles. It also brought machining “out into the open” so it could be located closer to the transmission assembly area, minimizing wasteful part travel throughout the facility.

Luckily for me, I got a chance to see how the tidy Van Dyke plant reaps MQL’s benefits during a visit this summer. While there, I also learned how the plant’s MQL efforts have matured over the past few years as it has become more proficient at near-dry machining.

The Technology of MQL

In short, MQL delivers a very small amount of coolant to a cutter’s edge in the form of an oil mist or aerosol, as opposed to traditional techniques of flooding the workpiece and tool with a substantial volume of liquid coolant. Just a tiny bit of that aerosol is left on the chips, workpiece and machine during the cutting operation. However, it’s nothing like what happens when cutting with flood coolant. (The link under Editors Picks at the right contains additional articles and a helpful video explaining more about the basics of MQL.)

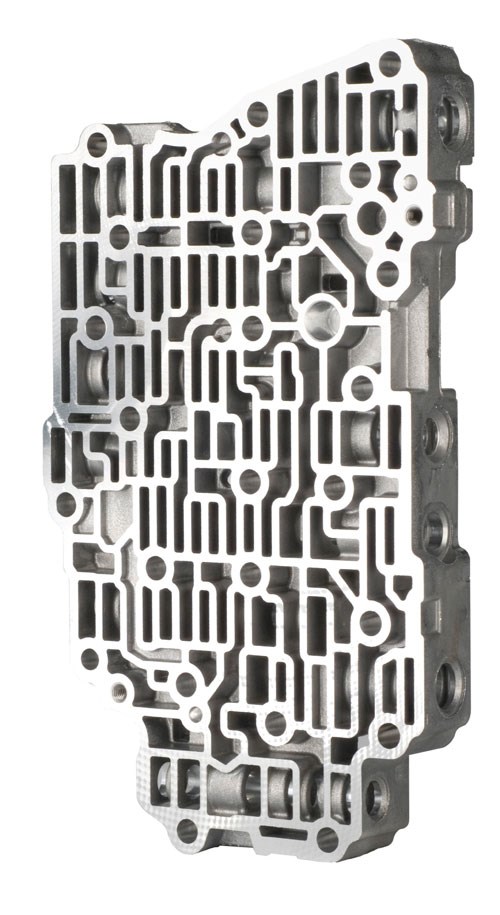

Van Dyke was not the first Ford transmission plant to implement this alternate coolant approach—that was the plant in Livonia, Michigan. In 2002, the Livonia plant began testing MQL machining on intricate valve bodies, which serve as hydraulic control centers for automatic transmissions such as the 6F six-speeds. The tests proved that MQL-machined valve bodies could be produced at or above the requisite tight accuracy and finish requirements, so the plant moved forward and installed a cell consisting of MAG Powertrain Ex-Cell-O XHC 241 linear-motor HMCs. At that time, those four-axis machines offered what the plant felt was the most advanced MQL system available. Installation of those machines, which are designed to deliver aerosol coolant through the spindle and tool, was completed in 2005. A nearly identical cell was subsequently installed at Van Dyke in 2006. Machines at both plants (166 total MQL machines between the two) are fed by gantry robots, while conveyors transport aluminum valve bodies, front cases and converter housings in, out and within the cells.

In 2007, the Van Dyke plant installed its second MQL cell. This second-generation cell uses 54 Specht 500D HMCs from MAG Powertrain and allows the plant to realize even more appreciable benefits of near-dry machining (I’ll touch on those later). This is due in part to machine design elements specifically geared toward MQL machining, which are worth mentioning here.

Each Specht machine has a precision dosing system integrated into its motorized spindle housing to enable effective aerosol delivery through tools. The machine’s CNC communicates directly with the MQL sub-system to adjust a dosing valve to deliver the proper amount of lubricant at the proper duration for a particular operation. (Specifically, a parameter in the part program varies the amount and duration of lubricant delivery). The lubricant is mixed with air to form the desired air/oil aerosol mixture, and the aerosol is then sent to the cutting edge through ducts in the tool. The aerosol is switched off when the tool is not cutting so oil doesn’t collect on the workpiece or machine surfaces.

These machines also enable effective chip handling. After a cutting operation, the machine’s A-axis trunion design enables the table to tilt and dump chips off the part and fixture. Steep, 55-degree walls inside the machine help near-dry chips fall down and into an exiting airstream. An enclosed machining environment kept under negative air pressure enables that airstream to pull chips and any oil mist out of the machine and through a centrifuge and filter system designed by Handte. Dry chips exit this system and collect in a hopper on the side of each machine, while clean, office-quality air is returned to the plant.

Specific, Significant MQL Benefits

MQL has delivered on the two prime drivers for its adoption at Van Dyke. From a total cost of ownership perspective, which considers machine cost, downtime, maintenance, floorspace, electricity usage, coolant management and related factors, MQL has yielded a 13-percent improvement versus comparable wet operations. As for environmental impact, MQL has been a key factor in the plant’s successful efforts in delivering no manufacturing by-products to landfill. But consider these other interesting ways the Van Dyke plant has benefitted from implementing its MQL strategy.

Sensors, switches and electronics last much longer. Automation, a key component of the Van Dyke plant’s machining processes, relies on switches, servos and other electronic elements that don’t particularly like wet environments. Since implementing MQL, the plant has seen a remarkable reduction in nuisance faults because there is no coolant that can find its way into electronic components. This ultimately leads to improved system uptime, which is vital for any high-production manufacturer. Uptime for traditional wet transfer systems was typically around 50 to 60 percent, whereas the MQL cells are delivering uptime in the 80- to 90-percent range. In addition, conveyors delivering parts in and out of cells no longer need coolant-collecting pans underneath them, because there’s no coolant to drip off of the MQL-machined parts being transferred. In wet operations, coolant left in conveyor catch pans for an extended period of time can become stagnant and malodorous.

CMMs are welcome on the shop floor without enclosures. CMMs were placed on the shop floor as part of the first iteration of MQL at the Livonia facility. At that time, the decision was made to enclose the units and isolate them in a controlled environment. Thanks to the inherent cleanliness of MQL and the Van Dyke plant’s temperature-controlled facility, CMMs are located on the shop floor without enclosures, reducing installation costs and enabling the CMMs to be positioned closer to the machines.

Aluminum chips go straight to the recycler. Because the chips produced with MQL operations are delivered to each machine’s hopper essentially dry, the need for time-consuming and costly recovery operations to separate coolant from chips is eliminated. Now, chips can be removed from each machine’s hopper and collected for delivery straight to the recycler.

MQL helps with the plant’s flat-floor efforts. Wet-machining systems carry a host of facility requirements. Support facilities not only need to provide coolant (via a stand-alone and/or a large central coolant system), but also must remove and/or contain the coolant. This ranges from a minimum of engineered floor drainage systems to contain spillage to lengthy trenches (or flumes) cut into the foundation for coolant/chip containment and flow out of the cell. Because MQL machines are essentially self-contained, there is no longer a need to create unique drainage and flume systems.

Transmission assembly can happen close to machining cells. Wet machining operations have traditionally been quarantined in some secluded, perhaps even enclosed area of the facility so as not to contaminate transmission assembly. That mindset carried over when the plant installed its first MQL cell, but now this is no longer the case. The second MQL cell is located out in the open and very close to the plant’s assembly area. In fact, the only physical element separating machining and assembly is a staging and storage area for machined components.

Bringing machining close to assembly in this way greatly reduces wasted part travel throughout the facility. It also allows tighter inventory control because the staging area, with its set number of storage racks, acts as a lean manufacturing supermarket that feeds assembly. The opportunity to over-produce and fall victim to hidden factory wastes have become greatly reduced.

Lessons Learned

The Van Dyke team faced an inherent learning curve when it moved from wet machining operations to MQL. For instance, when you’ve historically flooded a work zone with a large volume of coolant during machining, there’s a natural tendency to believe that more oil is better with MQL. In many instances, however, the team learned less is more in this respect.

MQL machining operations at the plant include drilling, milling, boring, reaming and tapping. The amount of oil used for specific operations is different and largely depends on tool diameter and feeds and speeds. Lighter cuts, such as boring operations on valve body spool bores, don’t require much oil. In fact, milling operations are often performed completely dry. On the other hand, drilling and tapping require more oil because greater friction between the tool and workpiece generates more heat.

Van Dyke doesn’t skimp on cutters for MQL, either. It uses primarily high-end tools from Emuge, Guhring, Mapal and Unimerco. This allows the machines to run as fast or faster with MQL than it could with traditional flood-coolant operations while producing products with exceptionally tight tolerances. For instance, valve body spool bores are held to micron-level precision, and the MQL processes have proven their ability to consistently produce at that accuracy level.

The plant has also adapted new machining operations for use with MQL. One example is a spline shaping operation for converter housings that uses shaping tools with conventional geometries. Had it not developed this process, converter housings would have to be delivered out of the MQL cell for wet machining of the splines. Now, all machining operations are performed inside the cell.

One other notable difference between the first MQL systems implemented and the latest-generation MQL cell at the Van Dyke plant is that the new equipment is located in a temperature-controlled area to help with machine thermal stability. This goes hand in hand with the real-time temperature compensation system on each Specht machine that constantly monitors the temperatures of the machine, the part and ambient air to help maintain consistently and precision. These are important factors when you consider the wide temperature fluctuations that occur in Michigan. Of course the personnel there appreciate the comfortable working environment, too.

Other MQL Efforts at Ford

Noting how transmission programs have benefitted from MQL, Ford is investigating how it might implement MQL for engine component production. Using MQL for ferrous materials requires different approaches, but the groundwork laid by the company’s transmission plants will go a long way toward helping the drivetrain side of the business quickly ramp up on MQL.

Related Content

AFT's Semi-Synthetic Coolant Extends Sump Life

Advanced Cool 2200 provides high visibility while machining, keeping the machine and parts clean with no odor issues.

Read More168 Manufacturing's Coolant System Automates Delivery

PMTS 2023: FullShop systems monitor and replenish all CNC machine sumps with optimized top-off ratios before the coolant runs low.

Read MoreHennig Inc. Acquires Industrial Coolant Systems

ICS develops and field tests high-pressure coolant systems, coolant filtration systems and other machine tool solutions.

Read MoreSTLE Hosts Co-Branded Tribology, Lubrication Events

The 2023 STLE Tribology Frontiers Conference and Tribology & Lubrication for E-Mobility Conference will provide attendees with two opportunities to share and learn the latest tribology and lubrication engineering science.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)