Tips for Controlling Oxidation and Pitting on a Wire EDM

Additives, machine settings, workpiece materials and current technology are factors in avoiding common problems with unwanted rust and surface defects.

Additives:

Additives do help in controlling oxidation and pitting of a variety of materials. These products help a great deal when cutting a workpiece with pre-polished surfaces.

Set the water conductivity to 5 microS or less, which is typically recommended for carbide, PCD, titanium, and fine finishes (<10 micro inches). This will also help keep bluing to a minimum on older non-anti-electrolysis generators.

Check water pH. Acidic detergents used to clean parts and tank will have a dramatic effect on parts rusting and will reduce the life of the deionization bottles.

Mix Workpiece Materials

With all the new and old types of alloys available, material incompatibility may cause surface issues. However, EDM field technicians have yet to document an instance where this situation has occurred.

New Machines

Most current wire EDMs are equipped with Anti-Electrolysis generators, some better then others. It basically comes down to how good the technology is and how fine of a surface finish the generator is capable of producing. A machine that is capable of producing a super fine finish (< 5 micro inches) can generate optimum surface integrity.

One example is the GF AgieCharmilles CUT 1000 that can machine parts with zero corrosion. The CUT 1000 is available in an oil version. With this feature, there is absolutely no electrolysis, corrosion and virtually zero recast.

Related Content

Sodick Die-Sinker EDM Fits Range of Automation Needs

The Sodick ALG EDM series doubles motor response speed for the development of accurate, high-quality molds, and is equipped with automated features for continuous operations.

Read MoreGF Machining Solutions' Wire EDM Provides Accurate Production

GF Machining Solutions’ CUT X 500 and CUT P 350 Pro wire-cutting EDM machines offer heightened accuracy, precision and productivity.

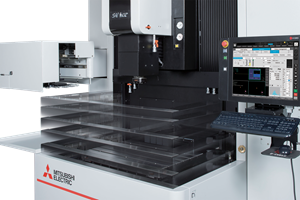

Read MoreMC Machinery's Sinker EDMs Feature AI Adaptive Control

The artificial intelligence adaptive control technology is said to help optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

Read MoreDielectric Oil Dramatically Reduces EDM Maintenance

Plagued by repeated small fires that interrupted its wire EDM throughput, this cutting tool manufacturer changed its dielectric oil and both eliminated fires and reduced its oil consumption.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)