Tooling Triad

To build exceptionally effective extrusion dies, this shop brings together strengths in three key areas: CNC machining, EDMing and tool room operations.

Unless you are in the middle of a forest, it’s hard to look around and not see something made of extruded plastic—the siding on a house, the trim on a car, the frame of a window sash. And even if you are in the middle of a forest, the trees you see are the source of a key ingredient in many of the most advanced and complex extruded products—wood. Wood fiber and wood flours are blended with plastic resin and extruded to make a wide variety of products such as deck planking, hand rails and architectural trim. To add to the growing use of plastic extrusions, emerging techniques allow materials to be extruded as foam and encapsulated in an outer layer that is rigid and weather resistant. Shapes with hollow cross sections in complex configurations are also possible.

All of these innovations depend on innovative designs for extrusion dies and related tooling. These designs, in turn, depend on advanced machining processes to turn them into reality.

CPC Tooling Technologies, a manufacturer of tooling for the plastic extrusion industry, is one company determined to keep up with developments in plastic extrusion technology. For one thing, CPC Tooling was once a captive tooling shop for its parent firm, Crane Plastics Co., LLC, one of the largest manufacturers of plastic extrusions in the United States and still one of CPC Tooling’s best customers. For another thing, as an independent company, CPC Tooling has to compete with other die shops for Crane’s business and that of other outside customers. All of these customers are looking for a source of high quality tooling delivered on time at competitive prices.

CPC Tooling’s strategy for meeting this challenge is based on a simple concept. The company must be able to build tooling not only for customers pioneering new applications, but also for customers whose conventional applications require faster running, longer wearing, more flexible and economical tooling. In-line tooling that turns extrusions into finished pieces ready for shipping is one of the shop’s specialties.

All For One, One For All

“Designing and building extrusion dies is as much an art as it is science,” declares Bob White, tooling manager at CPC Tooling. Mr. White, who has overall responsibility for the production of extrusion dies and related hardware for forming and cooling extrusions, explains: “You have to understand how material behaves as it undergoes the extrusion process and then use that knowledge to design a die and the tooling that goes with it. And you have to understand all of the machining processes that enable you to build that tooling.”

At CPC Tooling, those machining processes are available in three key areas, each located in its own facility within the sprawling Crane Plastics plant in Columbus, Ohio. Each one of those areas must be efficient and productive. Each must leverage the capabilities of the other two areas. Each must keep up with current techniques and equipment.

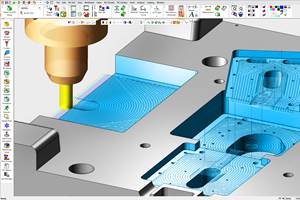

The CNC machining area is anchored by two vertical machining centers. These machines do the three-axis milling of complex die contours often referred to as coat hangers because of their distinctive spreading triangle shape, as well as two-axis milling of tool and die components.

The EDM (electrical discharge machining) area features one ram and six wire machines, whose ability to cut steep tapers in four axes is essential to the extrusion process, which converts material from a simple shape to a complex one. Wire cutting replaceable inserts, which greatly extend the life of a tooling system, is another critical job for this area.

A staff of skilled tool and die makers supplies all of the components that allow dies and other hardware to be assembled into a working system. Two toolroom areas equipped with precision mills, lathes and grinders provide the flexibility and expertise to build, troubleshoot and repair almost any die or tooling that comes their way.

“Every one of these areas is important,” stresses Mr. White. “Each one is vital to our strategy. Yet each area requires its own management style and has its own technology needs,” he says.

Capable And Productive

CNC machining has proven to be a key asset to CPC Tooling. CNC machining is both capable and productive. It is “capable” because it allows complex die contours to be machined in 3D. It is “productive” because it allows 2D work to be handled on a production basis, with pallet changers and shopfloor programming to keep the machine fully occupied.

The CNC machining department relies on two vertical machining centers, a VMC4020 model and a slightly larger VMC5020 model from Fadal (Chatsworth, California). These 22-hp machines have 10,000 and 7,500 rpm spindles respectively and 40-taper tooling. The 4020 also has coolant through the spindle. Both machines feature Virtual Gibbs as the on-board programming software.

Although three-axis contouring accounts for only 10 to 20 percent of the work that crosses these machines, it represents a critical application of CNC technology. CPC Tooling builds many kinds of extrusion dies, including those that produce wide flat sheets such as vinyl siding and building trim. Sheet extrusion dies feature a “coat hanger,” or flow pocket that has a characteristic triangle shape. Material entering the narrow end of this pocket encounters contours that spread and control the flow so that it reaches the die opening at a steady, equally balanced rate. The contours in the upper and lower portions of the coat hangers are produced on the VMCs. Tool paths for these surfaces are programmed off-line on an Anvil Express CAD/CAM system and downloaded to the CNCs via the shop network.

“These portions of the die determine how efficiently it will run,” Mr. White explains. “We’ve learned over the years how to design coat hanger geometry for some of the fastest running dies in the industry. Without CNC, we couldn’t machine that geometry in 3D,” he attests.

Now, thanks to CNC three-axis machining, the shop is applying this design finesse to some of its foam capping dies. These dies allow a substrate of foamed PVC plastic to be encapsulated within an outer layer of another material, usually a plastic that is eye-pleasing and more resistant to wear and weather. “We use 3D machining to produce a bleed-over pocket within the die that acts like a miniature coat hanger,” Mr. White says. The capping material feeds into this bleed-over pocket from the side through separate lines, and then it spreads around the substrate in an even layer.

According to Mr. White, this die design allows some profiles to run 40 to 50 percent faster than previous designs that used an angled slot running through the die to deliver the capping material. “Eliminating the angled slot simplifies die construction, so we can deliver a faster running die in less time and at a lower cost than before,” he says.

Bleed-over pockets are machined with solid carbide ball nose end mills, 0.125 inch in diameter or smaller, using the full rpm of the machine.

Most of the time, however, these same machines constitute the shop’s main production resource. Although it may seem odd to talk “production” in the context of one-of-a-kind extrusion dies, Mr. White thinks it is entirely appropriate, for at least two reasons. One, he says, lies in the fact that extrusion dies and related tooling typically require numerous 2D machining of standard features—bolt holes, water lines and the like. Two, CPC has developed a product line—a set of modular, interchangeable calibration tooling that can be mixed and matched on a standardized mounting rail to provide fast changeover. Components of this system are kept in stock for instant delivery to tooling customers.

“In 2D work, the goal is to keep spindle utilization high, comments Mr. White. ”That’s why we’ve equipped both machines with pallet changers. While one job is running, another job is all set up on the pallet changers. The spindle stops running only to change the pallet,” Mr. White explains.

Shop floor programming is the rule for two-axis work for the same reason. The CNC operators download the profile of a die opening, for example, and decide on the shop floor where boltholes and other standard features ought to be located. Stored templates are often used as a basis. The Virtual Gibbs software generates the corresponding machining routines based on the operator’s input. “They do this programming while another program is being executed in the background mode,” Mr. White says.

Sometimes the operators download tool paths generated for other operations. For example, the path used to wire cut the profile in a piece of calibration tooling is used as the tool path that a tapered end mill follows to create a clearance angle on the entry sides of the tooling. Using the same tool paths makes this step quick and simple on the CNC machines. “Adding this clearance makes for faster running calibration to boot,” notes Mr. White.

Revolution/Evolution

If ever there were a metalworking process that could be described as having revolutionized extrusion dies, it would be wire EDM. Wire EDM is perfect for cutting deep narrow slots in hardened material. Wire EDM made it possible to cut complex profiles without segmenting the die, thus saving time and simplifying the die making process. CPC Tooling acquired its first wire machine in 1977. Since then, both the EDM process and CPC Tooling’s applications for it have evolved and progressed.

Today, the shop has six wire machines, all of them from Mitsubishi EDM (Wood Dale, Illinois). The two newest are FX20K models that feature steep taper capability, submerged cutting, anti-electrolysis power supply settings, and 32-bit computer processing. According to Troy Kimmes, CPC Tooling’s lead programmer, all of these evolutionary features have enhanced wire EDM in extrusion die making, particularly the tapering capability. By programming the upper wire guides to follow one path and the lower guides to follow another, it is possible to create a wide mouth that smoothly tapers to the narrow slits characteristic of the die’s opening. This “streamlined” portion of the die represents a classic use of wire EDM.

Submerged cutting eliminates flushing problems in these complex wire cuts. Skim cuts, in which the wire electrode passes over previously wire cut surfaces to achieve a final dimension and smooth surface finish, benefit from the anti-electrolysis power supply settings. The 32-bit processing allows sparking conditions to be monitored closely for rapid adjustments that avoid wire breakage—a boon to untended operation, says Mr. Kimmes.

CPC Tooling has found numerous other applications for wire EDM beyond cutting die profiles and tapered streamlining. One of the most important is in the production of components for in-line fabricating and post forming operations. In-line fabricating allows an extruded shape to receive a variety of secondary operations immediately after it is extruded. Punches, dies, blades, slitting tools and so on are examples of wire EDMed parts for fabricating tools.

Another application of taper cutting is in transition guides that allow an extruded sheet to be formed and folded into trough or channel shapes. The shapes shown in the photograph below were formed from sheet extrusions by transition guides. By changing the transition guides, the same extrusion die can be used to produce a variety of finished products.

Transition guides usually come three or more in a set, each guide adding successively more “fold” to the extrusion as it is drawn through the calibration and forming tools. The wire cut tapered surfaces in these guides allow a smooth transition into the final shape. According to Mr. White, this is CPC Tooling’s faster, less expensive alternative to forming the extrusion within the die by attaching a series of plates at the front end.

“We also cut replaceable wear inserts using wire EDM,” explains Matt Fenneman, CPC Tooling sales manager and formerly the EDM supervisor. These inserts are cut with tapered sides so that they can be press fit into matching pockets in wear areas of the die. A similar approach using tapered cuts is applied to replaceable mandrels used to make hollows in the cross section of an extrusion. A typical mandrel features a web that attaches to the interior of the die mouth. The web holds the mandrel in place but lets material flow around it to reach the pin opening. Tapered locking bars on the edge of the web are press fit into mating pockets in the interior of the die. A worn or damaged mandrel can be pulled out and replaced with an identical copy produced using the wire path that cut the original.

Wire EDM is also used for repair and rework. Jobs farmed in from some local injection mold builders fill any remaining hours for the wire machines.

Tool Room Expertise

The third leg of CPC Tooling’s triad is its toolroom operations. These operations are currently divided between a group of eight tool and die makers who concentrate on extrusion dies and another group of four devoted to fabrication tooling. Both groups have been cross-trained so that these operations eventually can be consolidated into one area.

“We see our crew of tool and die makers as CPC Tooling’s hidden strength,” claims company president Herb Huchison. Because the toolroom areas are equipped with the usual mix of precision mills, lathes, grinders and conventional machine tools, these areas lack some of the glamour of CNC or EDM. Nevertheless, the toolroom operations are remarkable in several ways. It’s up to the tool rooms to put dies and tooling lines together and make them work to maximum effectiveness. Says Mr. White, “We focus on leveraging the skills and flexibility of our workforce here. We let these 12 guys make key decisions about how to build, adjust or repair dies and tools.”

The tool rooms work closely with the CNC and EDM departments, sending work back and forth to complete a project, with the tool room most often calling the shots. The tool and die makers, however, wind up juggling the most tasks spread over as many as six or seven projects in one day.

Toolroom personnel all work the first shift but have the option of putting in four 10-hour days per week. “This has been a popular move,” notes Mr. White, who is determined to keep his teams of tool and die makers intact. It’s not that these employees are pampered. “It’s demanding and challenging work,” Mr. White says. “Every hour has to count. We can trust them to get the work done, and we don’t use time clocks to keep track of their hours,” he says. CPC Tooling has acquired additional mills and grinders to make sure that one shift operation is not constrained by equipment availability.

Of the two groups, the one for fabrication tooling seems to face the most growth. In-line fabrication is growing in importance because customers are seeing the value of completing operations in one pass. By investing in in-line fabrication, customers can eliminate the cost of secondary operations, which add up on long running orders.

Next Year, Next Door?

According to Mr. Huchison, CPC Tooling’s long-term goal is to move into its own facility. This move would bring CNC, EDM and a consolidated tool room within one set of walls. Workflow and communication would benefit. Gaining extra room to grow is another motive.

The downside is being farther away from the parent plant’s production areas. This proximity has been convenient. Having a wide array of extrusion equipment nearby for testing dies and tooling speeds completion. Likewise, having a tooling shop under the same roof is handy when a worn die or a broken tool needs replacement.

CPC Tooling is eyeing a location a few blocks down the road from Crane’s main plant. It may very well be “the tooling triad’s” new

Related Content

Grob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreTool and Die Shop Discovers New Opportunities With First CNC Machine

In a shop that stamps millions of parts per year, the arrival of a CNC machining center is opening new pathways for production and business.

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)