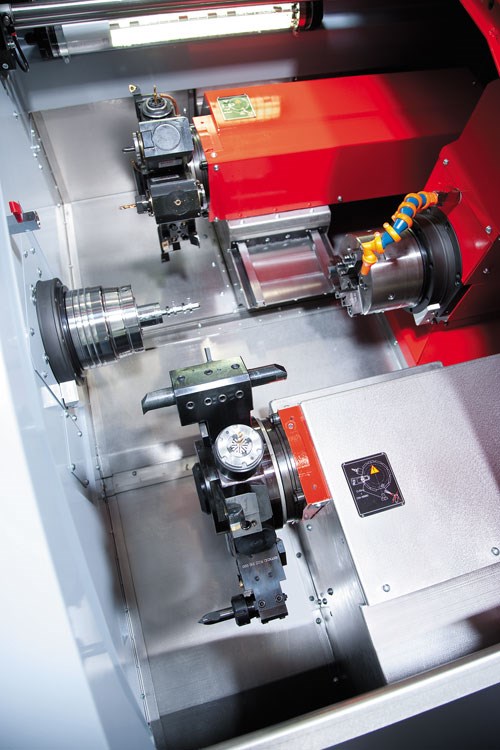

The Hyperturn 665 MC Plus is one of the larger turn-mill machines produced by EMCO Maier. This machine has twin spindles and two turrets. Its design makes it ready to be integrated with an automatic gantry loader/unloader. It handles barstock as large as 65 mm (2.5 inches) in diameter.

This machine is but one in the company’s wide range of turn-mill machines and CNC precision lathes. Although the company has offered its line of machines for commercial applications to U.S. customers ever since opening its first sales office in this country in 1977, EMCO Maier became best known in the United States for its line of classroom training machines. As a matter of fact, EMCO has been very successful in supplying machines designed specifically for schools and training programs.

At one time, the company had an 80-percent market share for this type of equipment in America. Until 2002, the company was selling well over $1 million of training machines in the United States, year after year. However, this market has been dwindling with waning interest and support for machining skills programs in U.S. vocational schools, junior colleges and corporate apprenticeship programs. This has prompted the company to renew its U.S. marketing efforts for strictly commercial equipment such as the Hyperturn 665MC Plus. Clearly, this is no classroom training machine.

EMCO Maier, headquartered in Austria, is a global company that produces turn-mills, precision lathes, vertical turning machines, milling machines and other types of manufacturing equipment. It has a sales presence throughout the developed and emerging industrial countries worldwide. No doubt, training machines are very important to the company. However, this segment of its product line has generally represented only 40 percent of global sales revenue. In Europe and other manufacturing economies, the company has a high reputation for its full-scale, “industrial strength” machines.

Even so, efforts to establish the company as a supplier of high-tech machines for commercial applications in the United States has met with only limited success. Its distribution channels, marketing efforts and support/service infrastructure never reached the “critical mass” necessary for U.S. buyers to give the company’s turning machines the attention they deserved.

Executives at EMCO Maier’s U. S. arm (based in Columbus, Ohio) are determined to change that. They have been revamping the company’s dealer network to better sell turn-mills such as the Hyperturn series and other CNC turning machines. They are building an inventory of spare parts and a system to deliver them in one or two days. Service technicians are completing their training and organizing for responsive deployment. As VP of Sales Dana Abshier sees it, these are all essential elements to attract U.S. buyers.

Of course, the company is still committed to training machines for schools and apprenticeship programs. “We expect this market to grow again, but our real opportunity for growth is supplying high-end turning technology to U.S. industry,” Mr. Abshier says.

He points to the Hyperturn 665MC Plus as a good example of the technology that characterizes this other face of EMCO Maier. Profiles of a production house and a job shop using this machine show the range of applications for its turn-mill capability.

A Representative Machine

Hyperturn is EMCO Maier’s designation for its turn-mill machines, all of which have two spindles and two turrets, a Y axis for complex milling operations and a B axis for working at an angle (optional). The Hyperturn 665MC Plus is roughly in the middle size range of this series. The 65-mm (2.5-inch) version is standard but a 79-mm (2.9-inch) barstock version is also available. Spindles are rated at 29 kW (39 hp). Each turret has 12 stations and both turrets can work on either spindle simultaneously.

The builder follows a modular approach to machine design, but sticks to some basic construction principles. For example, all machine features that influence workpiece geometry share the same bed, while other features are isolated on the underlying base. This keeps vibrations and heat from being transferred. Beds and bases are constructed of welded steel and filled with a vibration-damping material.

Provisions for automation are integral to the design of Hyperturn machines. The overhead gantry loader/unloader can be located on either side of the machine. This flexibility enables a bar feeder to be installed on the left side and a parts carrousel on the right, for example.

The two-spindle, two-turret machines in the Hyperturn line are complemented by the company’s Maxxturn series, which are single-spindle machines with two turrets, and its Emcoturn CNC turning centers for two-axis processing of shafts and chucked workpieces. (It bears mentioning that EMCO Maier also offers vertical turning machines and milling machines, although these products are not yet available in North America.)

The Hyperturn 665MC Plus is an appropriate representative of this broad line of turning equipment.

Productive in Production

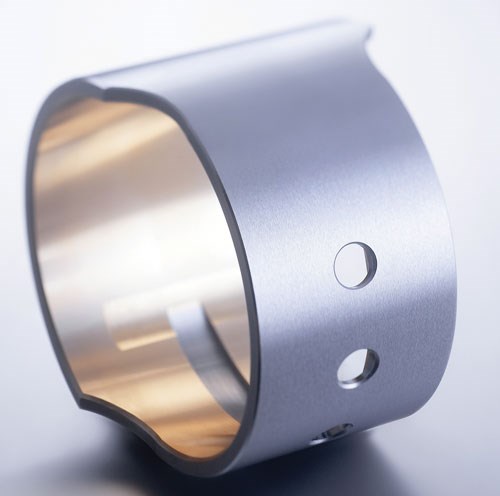

One class of potential U.S. users of the Hyperturn 665MC Plus is likely to look like Miba’s bearing and bushing plant in Laarkirchen, Austria. Miba is a global manufacturer of engine bearings, automotive components, automation systems and other high-tech products. Several Miba plants are located in the United States, including a bearing plant in McConnellsville, Ohio. Miba has more than a dozen EMCO Maier machines at its Laarkirchen plant, including at least four 665s, each of which has B-axis milling capability. These machines are used to make large piston bearings, a clear demonstration of how well-suited they are in a high-volume production application.

The 665s and most of the other machines from this builder are equipped with integrated gantry loading/unloading systems. These systems are designed and manufactured by EMCO Maier, an important consideration for Miba because it prefers a complete automation solution from one vendor, that takes responsibility for the entire system, with a common engineering philosophy applied to all components and control requirements.

The 665s are located in several production cells in which multiple machines share one operator/attendant. Miba’s mid-sized bushings are produced in these cells. The two spindles and two turrets on these machines enable them to complete most bushings in one setup. That is, milling and turning operations are consolidated on one machine—only final boring and grinding operations are performed on other machines.

For one style of bushing, the B-axis milling capability enables a contour to be machined on the rim of the part when held in the second spindle, thus utilizing “bonus free time” available while operations performed on the first spindle are completed.

Miba is an interesting case for U.S. manufacturers because it also faced the dilemma about relocating some operations to a low-wage country. About 10 years ago, the company considered moving production of bearings and bushings to cut costs for competitive reasons. An internal review concluded that production could remain in the Austrian plant if new machining resources combined flexibility, automation and affordability. Proposals from EMCO Maier met these criteria, but management hesitated because other builders had stronger reputations as suppliers of large, sturdy machine tools. However, initial experience with its first EMCO Maier turn-mill convinced the company to order additional machines. The stability of driven tools in the turrets was a key factor in this decision.

The builder is now the largest supplier of machine tools to this part of Miba’s Laarkirchen plant. The company attributes the successful retention of its bushing production in its home country to the economy and capability of the EMCO Maier machines.

Doing the Job in a Job Shop

If Miba represents the typical profile of the production-house user of EMCO machines such as the 665MC, Brisker GmbH represents the profile of the typical job shop user of these machines. Brisker is located on the outskirts of Vienna, Austria in an industrial park not unlike one you’d find in a U.S. suburban area (though missing the oodles of parking space we enjoy). It has 25 employees.

Brisker has one Hyperturn 665MC Plus, in addition to 16 other turn-mills and precision lathes from the same builder. This machine is used for larger parts such as stainless steel housings for automotive steering assemblies and aluminum end brackets for overhead stage lighting and sound systems. It is equipped with the optional Y axis that enables it to perform milling and drilling operations off the center line. The steering component, for example, features numerous off-center crossholes and holes at odd angles. Complex parts like these can be completed in one setup, yet the flexibility of the machine lends itself to fast change-overs—a true job shop priority. (Interestingly, the multi-axis capability of this machine enables it to engrave the customer’s logo on the curved surface of cylindrical-shaped aluminum end brackets.)

Johann Brisker, shop president and son of the company founder, says that having at least one turn-mill the size of the 665 is an important part of his business strategy, which is to attract mostly small, precision turned parts. “We have customers who come to us because we can handle the oddball large part in addition to the small turning capability they are looking for. This gives us an advantage as a one-stop shop for them,” Mr. Brisker says.

Although the 665MC Plus is a standout at Brisker, the machine emerging as the shop’s new mainstay is the Hyperturn 45, a counter-spindle, dual-turret turn-mill with a barstock capacity of 45 mm. The shop currently owns two but plans to acquire more. They will eventually replace its 10 Emcoturn 320 and 332 models, which are essentially older versions of Hyperturn 45. However, Mr. Brisker sees the new Hyperturn 45 as the next generation of job shop turning technology because it has a Y axis with a 70-mm range in the upper slide system.

Highly valued in this shop is the small footprint of the Hyperturn 45. Brisker’s shop floor is not cramped, but it is not spacious, either. Space has to be used judiciously, especially considering that most of the turning machines have either short or long bar feeders attached. By operating the machines with the bar feeders and arranging them in a kind of cellular pattern so they face each other, one employee is able to handle five machines, all running different parts.

Most importantly, the new machines are more productive than the Emcoturns they are replacing. According to Mr. Brisker, jobs moved to the new machines achieve a 20-percent increase in productivity, thanks to greater torque, faster rapid traverse moves and reduced tool changing time. Parts with high milling content often show as much as 35 percent more productivity.

Mr. Abshier expects the Hyperturn 45 to be especially well received by U.S. companies because of its size and capability. This model made its U.S. debut recently at the Precision Machining Technology Show (PMTS) in Columbus, Ohio, where it attracted the attention of both machine shops and traditional screw machine shops.

The Challenge

EMCO Maier’s U.S. management team understands the challenge of re-introducing the EMCO Maier brand in the U.S. market for industrial turning technology. Getting a top-notch service and support organization in place certainly reflects this grasp of the demands. Likewise, Mr. Abshier recognizes that success depends on targeting the right applications for complex, multi-sided workpieces in materials that include the tough-to-machine varieties. He believes that a niche supplier with the right technology has room to grow in these applications.

Significantly, Dr. Stefan Hansch, the corporate CEO in Austria, does not underestimate this challenge either. At a recent gathering of EMCO Maier dealers from around the world, Dr. Hansch acknowledged the importance of his company’s presence in the United States, especially at a time when a resurgence of U.S. manufacturing creates substantial opportunities for growth. “We expect to be a serious player in this critical market,” he says.

.png;maxWidth=300;quality=90)