Using Twin-Table Machines To Maximize Spindle Uptime

By integrating twin-table, bridge-style machining centers, this shop virtually eliminates spindle downtime during job chang-eovers. An operator can safely set up a new job on a table located outside the machine's workzone while the machine mills a workpiece fixtured on the other table.

Machine tools don’t make money while their spindles are idle. That’s what drives shops to reduce workpiece changeover time during part runs as well as teardown/setup time for new jobs.

Martin-Palmer Tool & Die recognized that minimizing spindle downtime would be critical to successfully entering new markets and winning new customers. As its name suggests, Martin-Palmer Tool & Die started business as a tool and die shop. That was in 1953. Over the years, the Dayton, Ohio shop gained expertise in designing and building specialized material-handling equipment for the automotive industry. Four years ago, however, that portion of the business began to slow. To adapt, the shop started pursuing short-run work that it felt would be too costly for U.S. manufacturers to outsource overseas. It moved away from the automotive industry and began delving into work for the military, commercial products manufacturers and OEMs in other markets. The net result is that now, no one customer represents more than 30 percent of the shop’s gross sales, says co-owner Rich Blevins.

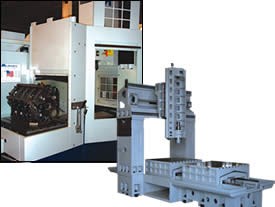

One option the shop considered to reduce spindle downtime was adding pallet changing systems to its existing VMCs. Instead, the shop decided to adopt an atypical, bridge-style machine tool platform from Milltronics that uses two independently positioned worktables. The shop purchased its first Milltronics TT24 twin-table machine in September 2006; its second arrived approximately one year later.

Here are a few reasons why the shop chose such an alternate equipment platform for part runs that fluctuate from 1 to 350, as highlighted by Mr. Blevins:

This machine design delivers on the shop’s need to maximize spindle uptime. An operator is able to safely set up a job on the machine table that is stationed outside the workzone while the machine is cutting on the other table enclosed inside the workzone. Often, the only spindle downtime is the time it takes to shuttle out a completed part and shuttle in a new workpiece. Doors on either side of the workzone close during machining operations to both contain coolant and chips and protect operators as they break down and set up new jobs on the second table. When the new job is set up, the operator presses a “ready” button, and the machine automatically switches the tables upon completion of the current job.

Having integral tables on a common machine base offers rigidity and a small overall footprint. The bridge-style machine has a vertical spindle and two pallets that move independently using linear encoders for accurate positioning under the spindle. Having each table permanently attached to a common base structure and traveling on shared ways results in a stout, sturdy system. This allows the shop to machine materials ranging from aluminum and low-carbon steel to tool and stainless steels.

The TT24’s 24-inch-square table size and healthy weight capacity allow the shop to machine large workpieces. The shop often performs repair machining work on diesel engine blocks such as the one shown on page 101 that weigh approximately 300 pounds. This table is also large enough to accommodate multiple vises, so the machine can complete numerous small workpieces in one setup.

The machine’s conversational control helped streamline the integration of the unfamiliar twin-table platform. The shop has other Milltronics VMCs with the manufacturer’s Centurion conversational control. Control commonality offered operators a level of comfort when learning the ins and outs of operating the new twin-table machines. Conversational programming at the machine uses a menu-based, question-and-answer format that prompts operators for job information and automatically creates the program from that entered data.In integrating this new machine platform, the shop found itself reevaluating the way it typically scheduled jobs for its VMCs. It discovered that the key to optimizing the effectiveness of the twin-table machines is coordinating workpiece cycle times when there are differing workpieces on either table. It is inefficient to mix jobs that have long cycle times with those that have relatively short cycle times.

Related Content

How to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

Read MoreChoosing The Right Grinding Wheel

Understanding grinding wheel fundamentals will help you choose the right wheel for the job.

Read MoreVolumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreRead Next

When Four Spindles Make Sense

For the right applications, four-spindle CNC chuckers offer practically zero delay for part loading. That’s because two spindles can be loaded while the other two are making chips.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)