Vacuum Workholding Improves Process Flexibility

Nature hates a vacuum but this captive Minnesota model shop loves one. Their world is one of high mix, low volume jobs. Vacuum workholding helps them better serve internal customers.

Most companies, regardless of size, organize themselves into departments that perform specific jobs. For example, a turning department in a metalworking shop is dedicated to supplying the enterprise with parts of rotation.

Dedicated departments, like turning, depend on other specialized operations in the company to provide support services: toolrooms, raw stock storage, manufacturing engineering and programming.

These departments don't have direct contact with the company's external customers, but they do work closely with internal customers—the various departments that use their services.

Fluoroware, Inc., (Chaska, Minnesota), has a model shop that is an excellent example of this type of facility. The shop's dedicated purpose is to fabricate prototypes and R & D product development, often one-offs, for the four businesses of the parent company.

Continuous improvement efforts tend to be less prevalent in dedicated, captive operations. In part, this is because there is a tendency for them to become rigid and bureaucratic primarily because of their internal focus.

Fluoroware's model shop is the antithesis of a rigid, change-resistant department. It is constantly in search of a better, faster way to get its products through the shop and out to its internal customers.

An example of this attitude of doing a better job is the model shop's application of a vacuum workholding system. We talked to David Gosewisch, the shop's lead worker, about how they use vacuum workholding. We also found out about the attitude within this shop and about the company that encouraged its implementation.

The Parts

Fuoroware is a very large technology support company for semiconductors and for related industries. Best known for its injection-molded wafer carriers, their products include wafer shippers and chip trays. Chip trays are used for bare die handling in the testing, assembly and packaging segment of the semiconductor industry. They also make trays for read/write heads.

They have a business that supplies fluid management systems—valving and tubing—for the semiconductor, chemical processing, pharmaceutical and biotechnology industries. From its Minnesota campus, which includes several buildings and more than a thousand employees, the company also manufactures advanced plastic products under various customer labels.

Tucked in one of the manufacturing buildings is a four-person model shop. The shop serves all of the company's businesses.

For machining, it must deal with a variety of materials that range from stainless steel and aluminum to an extensive selection of engineered plastics. These include Teflon, smoked polycarbonate, polypropylene, polyethylene and many spaceage plastic composites and others with such increasingly tongue-twisting names.

Most of the plastics include abrasive material in their compounds, making them not only difficult to machine, but very hard on the tools. Almost all of the tooling for the model shop's CNC mills, routers and lathes are carbide or titanium nitride coated to allow them tooling flexibility to cut any material called for.

The Problem

Dealing with the various material machinability characteristics is only one of the variables that this model shop must juggle. Figuring out a way to hold onto many of these materials is difficult especially if confined to using only traditional workholding methods and devices.

Mr. Gosewisch has devoted a great deal of time experimenting with various methods of "workholding" to effectively machine part geometry and material combinations that seldom repeat. Of course there are similarities, but it's rare for the shop to do the identical job twice.

For prismatic parts the shop uses workholding devices that one would expect to find—vises and clamps. Keeping workholders standardized and as simple as possible is a key for shops like this because of the ever-changing nature of the work.

Many of Fluoroware's model shop jobs are made from sheets of material. These are aluminum, stainless and engineered plastics.

Holding workpieces that are flat and/or thin is tricky for any manufacturer. And that's especially true when the material's processing specification calls for the part to be cut-through with a drill or mill.

"Doublefaced tape and clamps had been the norm for most of our flat-bottomed workpieces," says Mr. Gosewisch. "The problems with these methods often outweighed the benefits. With both the tape and the clamps, we had to leave material so we didn't machine into the table."

A vacuum chuck is often used to hold thin and flat workpieces. It works well for parts that "bottom-out." Its limitation, which is the same limitation as direct clamping to the worktable, comes on workpieces that need to be drilled or milled through. If the cutter goes through the workpiece into the vacuum chuck or worktable, either could be destroyed.

For Fluoroware to accommodate workpieces that called for break-through, secondary operations were required. So the shop would machine just short of the bottom of the workpiece and then it would be flipped and finished or taken to another machine.

The rough edge created by this two-step machining process needed deburring and finishing. The sharp edges were also a hand-trap that called for careful handling to avoid cut fingers and palms.

"Another factor," says Mr. Gosewisch, "is the delicate nature of the material in terms of holding tolerances. Using clamps, vises or other traditional holding methods often introduced deflection and distortion into the blanks to be machined. This required program changes at the machine to compensate."

Dimensional relationships between workpiece features are easier to maintain on a single setup operation.

"For much of our work, particularly in non-metallic materials, machining a complete part meant unclamping and reclamping and a lot of lost time."

Surface finish on most of this shop's materials is another consideration, especially on actual production parts where visible clamping marks are not acceptable.

A Tool

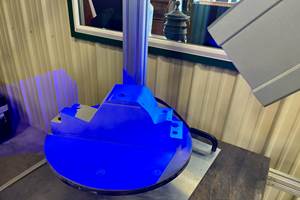

Mr. Gosewisch found help for these workpieces by using a product called Vac-Mat. It's a vacuum-operated workholding system designed to securely hold flat workpieces for machining operations including cut-through.

It's made by IBAG North America (Milford, Connecticut). The mat was originally developed in England to hold wing skin panels for aerospace applications. (The application called for replacing chemical machining operations with high speed milling. A method was needed to secure the panels to withstand the cutter forces generated by the milling operation.)

The expendable mat is placed between the workpiece and the worktable. By allowing drills and mills to cut through a workpiece and into the mat without touching the work surface, it imitates the way a kitchen cutting board protects a counter.

The mat is a buffer, thick enough to allow sufficient room to stop the Z-axis feed short of damaging the vacuum chuck on which it lies. If the mat gets cut beyond re-use, it is replaced by another.

How Does It Work?

The basic Vac-Mat system includes a modular vacuum chuck plate and a plastic mat. The vacuum chuck attaches to the machine tool as a sub-plate.

The system of chucks is modular and is made in single- and four-mat sizes. One or more of the 12 by 8-inch mats are placed on the chuck. If the work is larger or multiple parts need to be processed, more mats and chucks can be linked together.

The mat is about 0.060 inch thick. It gives sufficient distance between the bottom side of a workpiece and the vacuum chuck. If the cutter hits the rubber mat, it simply cuts the rubber without damaging the chuck.

The working side—the side contacting the workpiece—is covered with an evenly spaced distribution of large and small suction cups. Each of these cups is connected to the external vacuum pump by air lines that are molded into the mat.

Air requirement for pulling a sufficient workholding vacuum is 3.5 CFM per mat. "Distribution of the vacuum cups holds our parts very securely," says Mr. Gosewisch. "We machine right into them, giving us a finished part without burrs, and tolerances are right on the money. Holding the workpiece over a large contact area reduces the introduction of distortion that can come from clamping only on the perimeter."

For most machine operations, a vacuum pump is included as part of the Vac-Mat system. For Fluoroware's model shop, after a trial period to prove the concept, Mr. Gosewisch installed a central vacuum pump system and hard plumbed it to the walls near each machine with vacuum tubing. Flexible wire-reinforced vacuum tubes run from the hard plumbed system to each milling machine and a special CNC routing machine.

"We can run three- or four-mat setups at the same time on different machines," says Mr. Gosewisch. "This gives us a great amount of flexibility and productivity in meeting the needs of our design engineers whether they ask us to make Fluoroware products in development or parts for private label customers."

Putting It Into Practice

On any typical day, several jobs are being run in Fluoroware's model shop. Here are some jobs that were running during a recent visit to the shop.

On a Tree three-axis CNC mill, an aluminum plate was set up on two mats. "We could do the math and figure the holding potential for the mat on a workpiece based on area of contact and vacuum amount, but generally judging sufficient holding for the vacuum mat is based on experience and works fine for our jobs," says Mr. Gosewisch. He does suggest some caution if workpieces get fairly small. Covering more holes with a workpiece produces a better grip.

After a series of milling, drilling and boring operations, the model shop had created a control panel for a laboratory test station, ready for the various switches and gauges to be affixed. Despite the many holes, the plate held firm. "If enough `suckers' are not broken through, we can reuse the same mats for other jobs. Otherwise, we just throw them away. They're biodegradable, not affected by cutting fluids, and cost only a few dollars each."

Meanwhile, on the CNC router, a large 2 by 3-foot sheet of smoked polycarbonate was being pattern-drilled and contour-cut into two panels for special test stands. Eight mats were used to hold this job and most could be used again as there were plenty of "suckers" left. The abrasivefilled workpiece material was tougher than aluminum, but the vacuum system held tolerances to spec across the entire 2 by 3-foot expanse.

On another mill, a 2-inch-thick block of polyethylene on a single mat was being machined into a wafer carrier model that will be used to test the flex and seal of the final product assembly.

On a third mill, a polyethylene plate was being held in the vertical position on a single mat with the vacuum chuck clamped in a vise. It held firm against the deep-edge cutting forces generated by the mill, showing no distortion, slippage, or variance from spec.

Outside A Vacuum

Much has been written and "preached" about improving efficiency within a company's operation. Continuous improvement programs have proliferated in shops of all sizes.

Manufacturing has profited figuratively and literally from implementation of process improvement programs. Even more beneficial to most shops has been the general shift in attitude within the operating departments toward teamwork. "That teamwork extends from senior management to our four-man model shop," says Mr. Gosewisch. Innovation and experimentation are encouraged as part of the business's continuous improvement drive. Sometimes it means going beyond the conventional and finding solutions that are new and unique.

It is in small, incremental steps that efficiency gains are made. Knocking a few seconds off a process here, or eliminating an operation there, all adds up to a more efficient manufacturing operation.

In the model shop, they have gone beyond conventional workholding devices and practices. The environment that embraced application of the Vac-Mat product is indicative of this. They push the concept further on a daily basis.

On the other hand, if a better way to hold these workpieces comes along, it's a safe bet Mr. Gosewisch and his model shop will be giving it a try.

Related Content

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)