Vises Facilitate Swift Change-Overs, Reduce Errors

Syron Engineering & Manufacturing is a 28-year-old company specializing in the design and manufacture of tooling and sensors for industrial automation. One of the company's main fields of activity is the development of equipment to transfer sheet metal from one press operation to the next, primarily for automotive stamping.

Syron Engineering & Manufacturing (Saline, Michigan) is a 28-year-old company specializing in the design and manufacture of tooling and sensors for industrial automation. One of the company’s main fields of activity is the development of equipment to transfer sheet metal from one press operation to the next, primarily for automotive stamping.

In this context, Josh Jeffers, programmer and shop supervisor at Syron, explains that finding ever-faster ways to move these parts is one of the company’s ongoing challenges.

“As soon as we are able to speed things, then we are already looking at ways to go even faster,” he says.

At Syron, all steps of design, manufacturing, assembly and testing are carried out in-house. The tooling systems that the company develops consist of a combination of custom parts and standard components. Pressure to produce a variety of components faster led the company’s manufacturing team to re-examine its processes.

Management provided the staff with a copy of Shigeo Shingo’s book A Revolution In Manufacturing: The SMED System, at which point employees started to evaluate the machine downtime caused by setups. It soon became apparent that there was a considerable amount of idle spindle time associated with part change-overs for milling operations. Following the SMED principles, Syron conducted methodical time studies, analyzing the entire process to determine which steps could be converted from internal to external setup.

The bulk of the company’s milling is done on two OKK VP-400 two-pallet VMCs. Prior to implementing SMED, a typical setup required about 3 hours, or 183 minutes to be exact. One setup consisted of retrieval, assembly, installation and justification of each tool’s length; removal and replacement of jaws for the next job; installation and adjustment of workstops; and edge-finding to determine the work coordinates. During this time, the spindle was idle.

The company says that it employs a pool of 17 basic tools for most of its parts. These tools are now left on the machine at all times, reducing tool setup time to virtually zero. The remaining job-specific tools are assembled and pre-set externally. In addition, tool lengths are put into the program by the presetter. Now, internal tool setup consists of replacing a few tools in the machine’s tool changer in a few minutes.

“Our analysis of the workholding setup indicated that a completely different type of workholding system was needed to support external setup,” Mr. Jeffers explains.

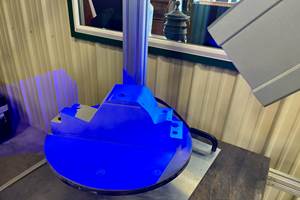

As a result, Syron selected a system of locator plates and twin vises from Bock Workholding (Ford City, Pennsylvania) that allowed it to use external fixturing. The fixturing is placed on the machine to obtain a constant positioning repeatability that is relative to the machine’s coordinates without the need for program adjustments.

The workholding system consists of four basic elements: locator plates, which are designed to offer an accurate pattern of locating and mounting holes identified by a letter and a number; a DexLoc locator pin, which is a double-expanding pin that allows vise positioning on the locator plate with a repeatability of ±0.0005 inch; twin vises, which serve as the carrier for the fixtures and have matching mounting and locating holes; and quick-change, snap-on jaws. The vises contain the clamping mechanism, and the jaw carriers and have accurate locators for the center jaw. The quick-change, snap-on jaws are machined to include all necessary stops and hold a part in an exact position. The jaws are stored away from the machining centers in coded boxes containing a raw and finished sample part.

The combination of these elements allowed Syron to convert all but a fraction of the workholding setup to external setup. Jason Beerens, tooling manager at Syron, does much of this work.

“When a new job comes up, we preset the tools, put them into a cart and adjust the program accordingly,” Mr. Beerens explains. “We then retrieve the jaws and place them in the cart with the sample parts, and it gets moved to the machine. All that is left to do is snap off the outbound jaws; clean; snap the new ones into predetermined locations on the twin vises; and then place the new tooling in predetermined positions in the changer, call up the program and go.”

Each vise holds two parts using three jaws—one fixed central jaw containing all of the locating surfaces and two movable jaws. “The fixed jaw is attached to the Twin Vise with two bolts, and the movable jaws are held from below the vise bed. This allows for ample room to machine even deep pockets” explains Joe Cousins, president of Bock Workholding. At Syron, the jaws are typically configured to the first operation on one side of the fixed jaw and the second operation on the other side of the fixed jaw. After these changes were implemented, the Syron team analyzed the new SMED implementation. The company says that the results are convincing: Typical change-over has diminished from 3 hours to 30 minutes, while spindle time is maximized. Syron also reports fewer operator errors and less scrap as benefits of making the switch.

Related Content

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreModern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreParts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreWhen To Use A Collet Chuck

Don't assume the standard chuck is the right workholding for every lathe application.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

%20and%20Josh%20Jeffers.jpg;width=700;quality=80)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)