Coke or Pepsi, PC or Mac, Republican or Democrat—life abounds with decisions that seem to boil down to two major alternatives. According to one waterjet equipment supplier, choosing a pump design doesn’t have to be one of them. The Quantum Electric Servo Pump (ESP) from

Techni Waterjet (Lenexa, Kansas) combines the advantages of the two most prevalent pump types while avoiding their drawbacks, says Chris McKinney, Techni’s national sales manager.

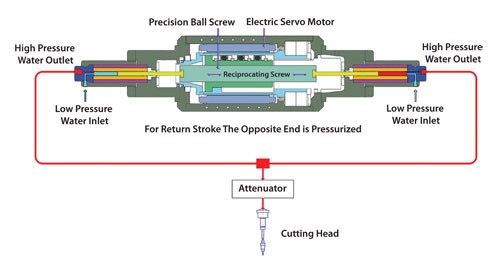

The two traditional types of waterjet pumps are direct drive and intensifier. Both draw, pressurize and eject water by moving a piston-plunger assembly back and forth within a sealed chamber. The difference lies in the mechanism used to drive the plunger. Direct-drive models use a crankshaft, whereas intensifier pumps use hydraulic cylinders. Conversely, Techni’s Quantum ESP uses an electric servomotor to drive plungers attached to a reciprocating ballscrew. Mr. McKinney says this design can generally match or surpass the performance of both direct-drive and intensifier models in the following areas:

Efficiency

Unlike the other two designs, the ESP uses only the power required for the cutting process, Mr. McKinney says. Like a direct-drive pump, an ESP can direct the lion’s share of power generated by the motor to creating the plunging action that pressurizes the water. In contrast, an intensifier must devote power to operating the hydraulic system, which also tends to require more cooling water than the other two designs to prevent overheating. Additionally, when an intensifier pump is idle, oil in the hydraulic system must be directed through a relief valve to stop the plunging action.

However, the ESP takes the efficiency advantages of direct-drive models a step further. That’s because direct-drive pumps must continuously expel water as long as the motor is on to avoid damage, he says. When the cutting head is closed, the direct-drive pump must drain water—and by extension, power—via a relief valve. The ESP has no such requirement.

Multiple Heads, Varying Pressures

Both ESPs and intensifiers can idle without displacing water or losing pressure. This ability, known as “dead-heading,” makes these designs practical for driving multiple cutting heads and for varying the pressure of the stream. However, an intensifier’s hydraulic cylinders operate at a set speed. As a result, resuming the cut after dead-heading can result in an unwanted spike in pressure as the plunger restarts. This isn’t a problem with the ESP because the servomotor provides infinite control, enabling controlled starting and stopping of the plungers.

Maintenance

Both intensifier pumps and ESPs typically require less maintenance than direct-drive models, Mr. McKinney says. A major reason for that relates to the speed at which the plunger reciprocates. At the same pressure setting, he explains, a direct-drive pump will stroke more times each minute than either an intensifier pump or an ESP. This places additional strain on seals, tubing and other critical components. Avoiding unwanted spikes in pressure that can result from dead-heading intensifier pumps further reduces maintenance requirements for ESPs.

Footprint

Both direct-drive and intensifier pumps are driven by electric motors housed separately from the actual pumping apparatus. In contrast, the servomotor that drives the ESP is hollow and wraps around the reciprocating ballscrew. This minimizes the floor space requried for the pump. Mr. McKinney adds that this advantage is more pronounced when comparing the system to intensifier pumps, which often house large drums of hydraulic oil in addition to the motor and the pumping apparatus.

Real-Time Diagnostics

Unlike the motors employed by the other designs, the Quantum ESP’s servomotor provides direct feedback, similarly to servos on machine tools that relay positioning information to the CNC. Mr. McKinney says this enables operators to monitor the pump’s operation in real time—either at the control or from any device with Internet access—and detect abnormalities that might indicate potential problems down the road.

Other Considerations

Other notable features include quick-change seal components and a structure designed to provide easy access to internal components for maintenance. Mr. McKinney also notes that the pump’s efficiency in terms of power, water and oil consumption benefits not just the bottom line, but also the environment.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)