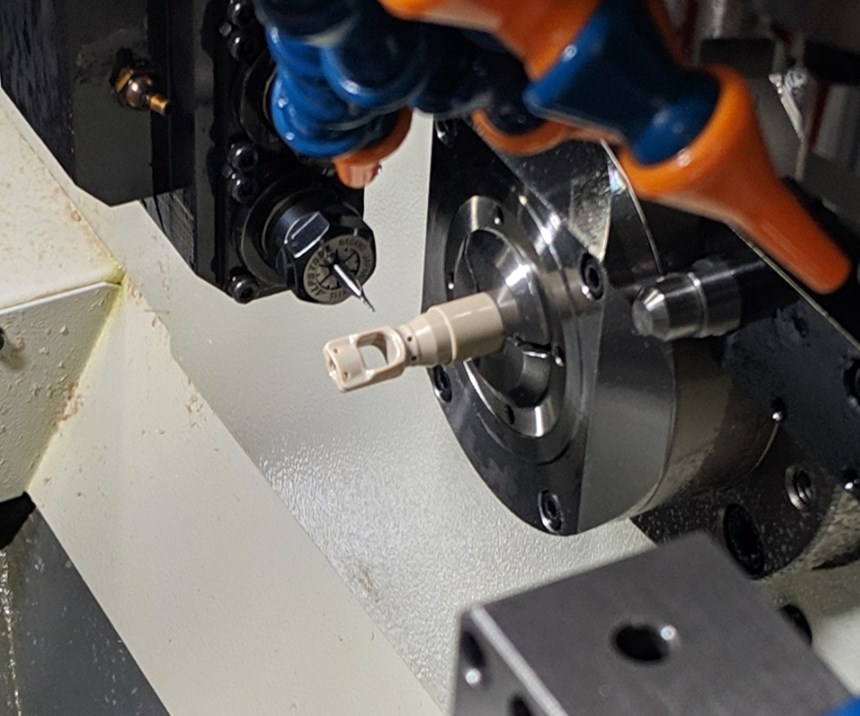

For Challenge Machine, the complex medical part shown in the slideshow above led it to consider a Swiss-type lathe having a programmable, swiveling B axis with live tooling stations.

The Blaine, Minnesota, shop that recently became certified to ISO 13485 had been running the implantable, medical-grade polyetheretherketone (PEEK) part used in knee replacement procedures across two CNC machines. A five-axis machine milled much of the part (cycle time was 45 minutes) and a three-axis machine completed it (cycle time was 15 minutes). Today, this part is machined complete in 15 minutes on a Marubeni Citizen-Cincom L220 Swiss-type lathe.

Challenge Machine purchased its first L220 in 2015. It has since added two more. The PEEK component is one of many examples of parts machined complete on the B-axis Swiss-types, some of which previously ran across multiple mills. While these Swiss-types are turning centers first and foremost, B-axis live tooling posts enable them to function as five-axis mills with bar feeders that enable long stretches of unattended operation. During a recent visit, I learned how the shop is benefiting from this technology, some of the challenges it faced adopting it and some of the lessons it learned along the way.

Swiss Start

Jim Betland launched Challenge Machine in his basement in 1999. A large portion of the business was devoted to micromachining parts for the semiconductor industry. Now located in a 16,000-square-foot, environmentally controlled facility just north of Minneapolis, the shop still performs a good bit of micromachining work for that and other industries, including automotive, medical and defense. In fact, it recently added a Sodick UH430L CNC mill with 60,000-rpm spindle and pallet changer to enable long stretches of unattended micromachining.

Although not all the shop’s work involves micromachining, nearly all of it is complex. This is one reason why the shop added its first couple Swiss-types. Although these machines lacked B axes, live-tooling stations enabled them to perform milling work. One featured a subspindle that could pick partially machined parts from the main spindle for backworking operations.

The L220s were the shop’s first B-axis Swiss-types. “There certainly is a learning curve with these machines,” Mr. Betland says. “Shops new to these types of Swiss-types should expect it to take time before really being able to fully utilize the B axis.”

The shop put machinist Eric Grue in charge of learning the ins and outs of B-axis machining on that first L220. He was familiar with Swiss-types, and with Marubeni Citizen-Cincom equipment in particular, but this was his first experience with a B-axis model. “It took us a year before we were really taking advantage of the B axis,” he says. “For a while, we were using it only for cross working normal to the barstock or straight-on backworking.”

Now, the shop performs quite a bit of drilling and milling at angles not normal to the barstock centerline (the B axis offers 135 degrees of rotation). One trick Mr. Grue discovered was using an end mill instead of a spotting tool to create a pilot hole for angular drilling. The tool’s flat end prevents it from “walking” as it engages with the material at an odd angle. In addition, he notes that very small depths of cut and slow feed rates are necessary when micromachining using the B axis (i.e. when using tools with diameters less than 1 mm). This is because when the linear and axial axes move in synch, they put a lot of stress on the tool. For instance, the shop recently used a 0.5-mm drill applying a 5% depth of cut and 60 mm per minute feed rate.

However, he also discovered that developing tooling strategies for this type of machine requires ingenuity. Unlike CNC milling machines with high-capacity toolchangers, Swiss-types have a limited number of tool stations. The L220s have five turning stations, three crossworking stations for the main spindle, six opposing stations (three live, three static), eight stations on the back post (four live, four static) and four live stations on the B-axis tool post. “There simply isn’t the capacity to use specials like custom form tools as we might on a mill,” Mr. Grue says. “We have to be creative in how we use ball mills, boring bars, grooving tools and the like to create the complex features parts need, such as the bell-shaped ID geometry on the PEEK knee-replacement part.”

There are also various ways a part can be oriented within the volume of the barstock. Part orientation is sometimes dictated by what feature machined on the main spindle would have sufficient length that the subspindle can grip. This is typically a round feature, but in one instance, Mr. Grue milled a square profile into an ER collet to clamp on a mating square feature on the end of the part.

Material Considerations

Challenge Machine benefits in that the three L220s can cool parts using oil or compressed air. Oil coolant is commonly used when machining metals. In fact, the newest L220 has high-pressure coolant delivery to improve chip evacuation when deep drilling in 17-4 and 304 stainless steel.

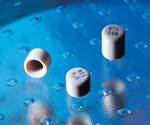

Compressed air is useful for plastics because oil can contaminate those materials. The shop can change from running metal parts to running plastic parts by simply cleaning collets and guide bushings and wiping coolant off toolholders and coolant and compressed air lines. This isn’t a meticulous process. The key is to ensure there is no remaining oil that could drip onto the plastic material. Scheduling medical and plastic jobs in batches helps minimize change-overs. Challenge Machine also uses compressed air to eject delicate plastic parts from the subspindle because the machine’s ejector pin could leave a mark.

One technique specific to PEEK parts involves minimizing the length of the barstock “remnant;” that is, the remaining end of the barstock that cannot be machined due to the distance between a Swiss-type’s main collet and signature guide bushing. Remnant length typically ranges from 7 to 12 inches, which can be costly for customers that supply the material (a 36-inch length of this material costs approximately $1,800). Machined steel extensions that screw into the end of the bar reduce PEEK remnant length to 2 inches.

Looking Back, Looking Ahead

In hindsight, the shop should have considered machines with barstock diameter capacity of 32 mm rather than 20 mm to accommodate larger parts, Mr. Betland says. It also likely wouldn’t have purchased multiple 80,000-rpm, high-speed electric spindles as it did for its first two L220s (one machine offering 6,000 rpm for live tooling and the other 9,000 rpm). “Very high rpms aren’t necessarily needed for machining with small tools,” Mr. Grue explains. “The 9,000 rpms that two of our L220s offer is sufficient for that. Plus, the electric spindles have minimal torque, so you can’t get a decent depth of cut in metals using them.”

Moving forward, Challenge Machine is considering using chilled cooling methods such as compressed CO2 or dry ice blasting for machining plastics to reduce the chance of creating burrs on the part. Mr. Grue explains that when machining plastics, the tool and base part material take the heat instead of the heat coming out with the chip. The higher the base part material temperature, the more likely the cut material is to fray and stay connected to the part. Using cold air as the coolant combined with sharp, uncoated cutters reduces the likelihood of this happening.

It also will soon switch Swiss-type programming to GibbsCAM CAD/CAM software, which it currently uses for CNC mills. The shop appreciates the software’s simulation capabilities and its MultiBlade toolpath strategy. It currently uses MultiBlade to machine plastic impellers on its five-axis machines, but would like to transfer that work to the L220s to reap the advantages of unattended machining.

Related Content

Ametek EMC Laser Cutting System Offers Through-Part Cooling

The new laser cutting system offers comprehensive Swiss machining capabilities, as well as through-part cooling and automatic part-handling options.

Read MoreFive-Axis Turnkey Machine Halves Medical Shop’s Cycle Times

Horizontal five-axis machines cut cycle times in half at ARCH Medical Solutions – Newtown. But its leadership gives equal credit to a surprising factor: the OEM’s service department.

Read MoreSolidCAM Wants to Help Machine Shops Get into Additive Manufacturing

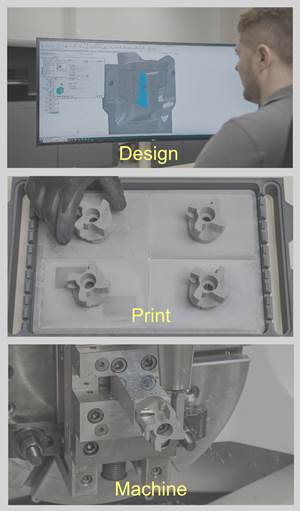

SolidCAM's partnership with Desktop Metal is aimed at making additive manufacturing more accessible to job shops and other manufacturers.

Read MoreModern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreRead Next

A Quick Look At PEEK Machining

The use of PEEK polymer for medical implant devices is on the rise. A supplier of this material offers cutting tool tips for shops that may soon add PEEK machining to their list of capabilities.

Read More3D-Printed Medical Drills Keep Bone Cool During Surgery

Drills made via additive manufacturing cut bones without causing thermal-induced damage thanks to internal cooling channels.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)