MMS Blog

Combining Functions With User-Defined G & M Codes

CNC programmers gain flexibility when using custom macros to define G and M codes themselves.

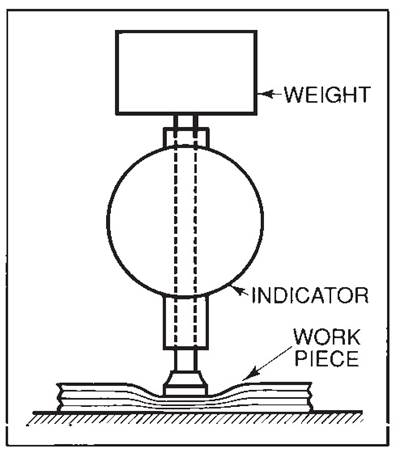

Read MoreThe Many Ways of Measuring Thickness

While it may seem to be a straightforward check, there are many approaches to measuring thickness that are determined by the requirements of the part.

Read MoreMaking the Most of Mixed Toolholder Assemblies

While nearly all ER systems will have cross compatibility, they’ll have small differences across manufacturers that make their implementation at the shop level not as standard.

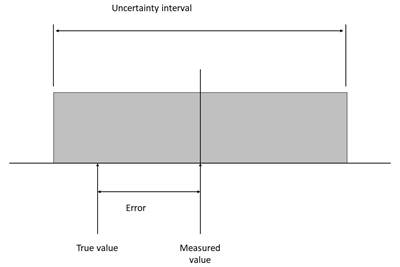

Read MoreHow to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read MoreThe Resurgence of 'Shop Class' in American High Schools

From the 1990s through the 2010s, most traditional “shop classes” disappeared from middle schools and high schools across the U.S. — one of the many issues that helped create today’s skilled labor shortage in metalworking and CNC machine shops. Here’s one solution that deserves more attention.

Read More4 Ways to Stop a Cycle to Allow Operator Intervention

Completely automatic operation should always be the goal, but there are situations that require operator intervention during the CNC cycle.

Read MoreMetalworking Activity Continues its Roller Coaster Year of Contraction

October marks a full year of metalworking activity contracting, barring just one isolated month of reprieve in February.

Read MoreQ&A: How a Self-Taught Machinist Started His Own Business

This machinist found an opportunity in a niche market and decided to learn machining and create his own business. Here's how he did it.

Read MoreSteady Culture, Flexible Plans Enable Custom Tooling Success

By late 2019, West Ohio Tool’s client list only spanned one page. The company overhauled its culture and is now on track for its most successful year ever.

Read More3 Lessons Job Shops Can Learn From Laser Cutters

This laser-cutting “job shop” designs its processes to make high-mix, low volume work profitable.

Read MoreShould Blisk Machining be in Your Growth Plan?

Blisk machining offers a great business opportunity but requires technical expertise in machining difficult materials with multi-axis machines. The right partner can help you get started.

Read MoreCauses Are Complex: The Case for Choosing the Right Failures to Analyze

The nuance and complexity of failure in bearings is enough to illustrate the difficulty of failure analysis in general, and how much consideration this analysis deserves.

Read More

.png;maxWidth=300;quality=90)