A Stitch in Time—A New Core Retention Function for Wire EDM

When running a wire EDM such as the FANUC RoboCut C800iB, an automatic routine in the CNC program adds a "stitch" at a few strategically placed locations around the periphery of the core. By holding the cores in place until the entire job is finished, multi-workpiece cutting processes are able to run in an extended, unmanned mode.

One of the long-standing challenges in cutting a workpiece with a wire EDM is keeping the core from falling away or slipping out of place as the electrode wire completes its path to form an opening in a solid. The core, also called a slug, is the piece of material freed from the workpiece by the wire. Of course, in some cases, that piece is the one that is wanted and the leftover solid is the unwanted “web.” Either way, it is necessary to stabilize that core to prevent it from falling into the work tank or lodging itself against the wall of the opening where the electrical wire cannot get past it.

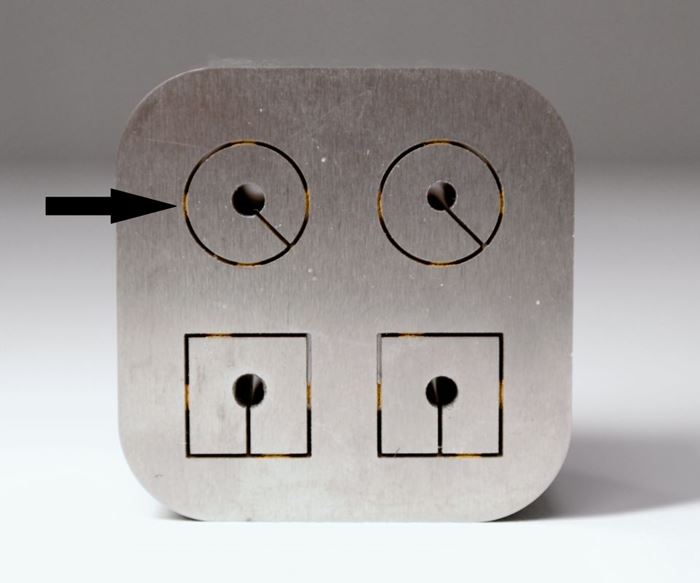

Methods Machine Tools, the U.S. importer of FANUC RoboCut wire EDMs, says that a new slug-retention technology introduced on the α-CiB series of wire EDMs makes it possible to hold the core in place with an automatic routine in the CNC program. This routine, which can be entered by the operator at the machine's CNC unit, adds a "stitch" at a few strategically placed locations around the periphery of the core. This stitch is created by intentionally causing the wire to go into a "reverse electrical discharge machining" mode in which brass from the wire is deposited in the kerf between the core and the parent material. This brass deposit forms a tab that is a few millimeters deep and wide at the top of the channel formed by the wire-cutting action.

This tab is sufficient to hold the core in place until the job is completed. When the finished plate, which is still holding all the stitched cores in place, is removed from the machine, a tap of a small hammer is all that is needed to break the tab and enable the cores to drop away. The remaining portions of the tab can be removed with a few strokes of a file or abrasive deburring stick, Methods says. Removing the cores at this point protects the machine and the workpiece.

In the past, procedures to retain the slug involved stopping the machine so that a dab of glue or a small brass strip could be inserted to hold the core in place. After each stop, the operator had to initiate a wire rethreading routine to commence cutting again. Usually, these "glue stops" were written into the CNC program during the programming step. The core-stitch function on the FANUC machines does not have to be pre-programmed. Stitch points are set directly at the machine, sparing the programmer of this task.

According to Methods, incorporating these stitching functions lengthens the actual machining time somewhat; however, eliminating other steps to secure the slugs reduces overall processing time to complete the job. With the core-stitch function, the more openings that are being made at one time, the greater the overall time savings. In addition, this stitching function is automatic, enabling multi-workpiece cutting processes to run in an extended unmanned mode.

How the EDM wire-cutting process is able to create the tab that stitches the core in place is worth a note because it reveals an understanding of the "spark erosion" concept. An energized electrode wire is able to remove material efficiently because the machine's power supply rapidly turns on and off the flow of electrical current, with each pulse creating a small discharge or “micro explosion” between the surface of the wire and the surface of the workpiece. These pulses of energy occur many thousands of times a second. Although this discharge is highly localized (on a microscopic level, in fact) the discharge of energy creates a temperature high enough to melt the workpiece surface and create an expanding gas bubble beneath the spot. When this bubble bursts, it disperses molten material as tiny particles that quickly solidify to be swept away by the flushing action of the flowing dielectric fluid.

Normally, controlling numerous variables related to the pulse of electrical energy enables the electrical wire to minimize loss of its mass during the cutting process. However, these variables can be manipulated to cause a form of electroplating. In this mode, particles of brass from the wire are released and allowed to migrate to the side walls of the kerf being cut in the workpiece. To create the tab, the table travel slows down so that the amount of electroplating of the brass wire to the top of the kerf will be enough to fill in the kerf completely behind the wire as it continues to move forward in the direction of the cut. When a tab of sufficient length is complete, the power supply returns to the settings for standard cutting. At the same time, table travel goes back to its normal speed, and the process no longer leaves any tab.

The company also points out that the RoboCut α-CiB series is distinguished by other features. The series includes the C400iB, C600iB and C800iB models. They are designed to deliver high accuracy via thermal displacement compensation to accommodate room temperature fluctuation. The company reports that the machines provide 0.0002-inch positioning accuracy and 0.0001-inch repeatability, even during long burns. A moving-tank design also contributes to accuracy. Unlike a moving-column design, which can make the lower-guide position susceptible to inaccuracy due to pitch and yaw of the column, the column and lower arm of the moving-tank design are fixed so that the table and workpiece move instead of the column.

The largest machine in the series, the C800iB, accommodates a workpiece as large as 49.2 by 38.4 by 11.8 inches and as heavy as 5,000 lbs. It is designed for applications such as large molds, stamping dies and complex aerospace parts. This machine’s X-, Y- and Z-axis travels measure 31.50 by 23.62 by 12.20 inches; U- and V-axis travels span ±3.937 inches. The FANUC 31i-WB CNC has large program storage capacity and remote PC access from handheld or desktop devices. The control is equipped with FANUC’s Intelligent Human Machine Interface (iHMI) as well as Cut Linki 2.1 software, which enables remote monitoring of as many as 32 FANUC wire EDMs for consumables life, machine efficiency, utilization time and maintenance service.

A 3D Compensation Function reduces the need for indicating-in workpieces, enabling the operator to measure the flatness of the workpiece quickly. The system then automatically tilts the wire to make it perpendicular to the surface of the work, regardless of its orientation when fixtured in the tank, Methods says.

Related Content

Understanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.

Read MoreInside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)