Faster, Ever Faster…

If your shop bought faster machine tools recently, there is good news.

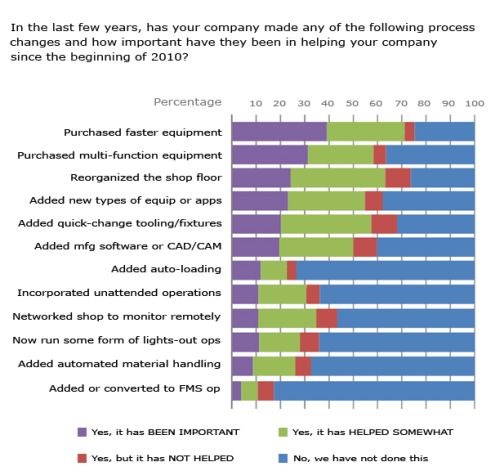

If your shop bought faster machine tools recently, there is good news. According to North American metalworkers responding to the 5th annual Metalworking Operational Trends Survey, “purchasing equipment that runs faster than current process” was the number one change they made with the most important impact on their business. And not just last year—upgrading existing processes with faster equipment has been the number one process change shops have made for five consecutive years, survey respondents say.

When I stopped selling machine tools 15 years ago, machining centers with 15,000 rpm spindles and turning centers with servo-driven turrets were helping shops cut cycle times. Since then, the “faster machine” trend has continued relentlessly, with faster tool change and reduction of other non-cutting machine time, including faster loading and unloading. Enhanced computing power to maintain optimal cutting rates in complex 3D parts has played a big role in cycle time reduction. And though it’s not new, simultaneous cutting with more than one tool has spread far beyond the screw machine shop to reduce cycle times.

In 1995, I wondered when machine tools would hit their speed limit. Back then, I was stuck in linear thinking in an analog world. But the “digital revolution” has changed the way I think, showing how far technology can advance beyond our expectations. In 1995, not many imagined we’d have unlimited access to information through the Internet. Almost overnight, thousands of digital devices have made their way to market. From entertainment to education, and from science to warfare, these devices have removed limits and altered our reality.

I don’t know where or how the next breakthrough in machine tool speed will happen, but as sure as Steve Jobs is working on Apple’s next big digital thing, a breakthrough in machine speed will happen and eventually give way to something faster yet. About this, I am sure. If we’re still polling manufacturers 20 years from now, I’ll bet they’ll say that “purchasing equipment that runs faster than our current process” was the most important change made.

Techspex and the Research Division of LoSasso Advertising Inc. conducted the 5th annual Metalworking Operational Trends Survey in August and September 2010. A link to the full survey report will be included in my next post here in about a week.

.png;maxWidth=300;quality=90)