How Machine Tools Can Save Energy

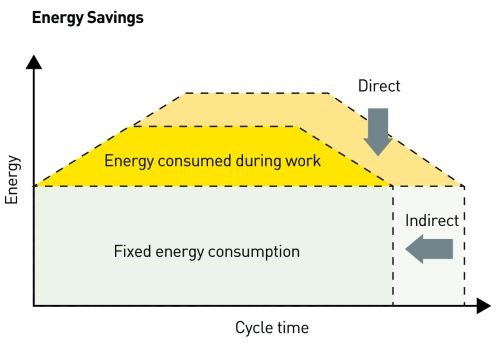

It starts with energy-efficient designs of the servo and spindle systems. This article introduces useful concepts such as the difference between direct and indirect energy consumption.

Energy usage is becoming a more important factor in determining the overall efficiency of automation systems, including CNC machine tools. Conserving energy cuts costs and protects the environment. An article by Paul Webster, engineering manager at FANUC FA America, explores the topic and focuses on the value of modern electrical motor design for CNC machine tools, injection machines and other automated production equipment. “Energy Saving Designs in Factory Automation Equipment” also introduces a number of key concepts in energy consumption and efficiency strategies.

Related Content

-

Weiler to Debut New Automation Features For Its Lathes

Weiler’s V 110 four-way precision lathe introduces features new to the U.S.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)