Published

Mazak Showcases Kentucky Machines for Global Export

The United States is a great place to design and build world-class machine tools. That’s one of the messages Mazak Corp. hopes visitors to its Booth S-8300 will take home with them.

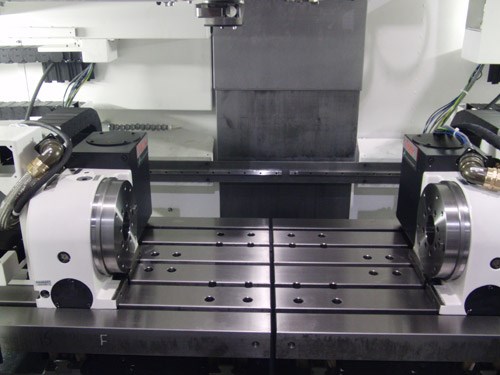

This split-table VMC typifies the innovation inherent in Mazak machines that are designed and built in Kentucky. The inset shows the tables locked together for long workpieces.

The United States is a great place to design and build world-class machine tools. That’s one of the messages Mazak Corp. hopes visitors to its Booth S-8300 will take home with them. Of the 22 machines on display, eight are models entirely designed and exclusively built in Florence, Kentucky. Although these designs may reflect specific needs and interests of U.S. buyers, all of these machines will be marketed globally. Mazak’s Florence-based design team has been creating models of its own since 2005 but has become more prolific in recent years, as the record number of Kentucky-designed and built machines at this show attests.

A good example of a machine whose inspiration, design, development and construction took place in the U.S. is the VCN 530C II TT vertical machining center. This VMC features an innovative split-table design that enables it to function as a two-pallet machine with an integral pallet changer or serve as a VMC with a single, extra wide table for twice the X-axis capacity. This is accomplished by making it possible to lock the two tables together and sync the servo systems so the X-axis travel is fully integrated. With tables locked together, the machine can handle parts that require an X-axis stroke as long as 58.66 inches. When the tables are separated for twin-table operation, each has a 25.4-inch X-axis capacity. In either mode, the Y axis is 21.0 inches.

Rick Bramstedt, product manager for Kentucky products, says the design concept has numerous advantages. The main one is increased flexibility for job shops with production work that wish to accommodate extra-long workpieces without investing in dedicated equipment. These oversized jobs can be mixed into the workflow less disruptively. Changeover to locked-table operation can be completed in less than 15 seconds.

The twin-table design also takes up less floor space than a similarly sized VMC with a pallet changer. For faster, simpler installation, the machine ships on one pallet instead of three separate pallets for machine, pallet changer and chip conveyor. In production, operations can shift from one table to the other in less time than it takes to change pallets on a conventional pallet changer. In addition, both tables can be equipped with rotary devices for four-axis machining, whereas pallet-changing machines are usually limited to one rotary table because of difficulty managing cable connections.

Bramstedt says the design also is economical to produce in the Florence factory because it uses modular components shared with other popular machine designs. Only the base casting is specific to this machine. The pallet changer is integral, so axis alignment can be performed at the factory, rather than in the field by the installer, to save the buyer time and money.

Other notable machines on display in the Mazak booth include the Variaxis i-700 and the Integrex i-400ST. The Variaxis i-700 is a five-axis machining center with a tilt/rotate trunnion table designed to reduce setups for complex workpieces and curved surfaces requiring high accuracy. With Y-axis travel of 43.3 inches (1,100 mm) and X-axis travel of 24.8 inches (630 mm), the machine can accommodate workpieces as large as 33.46 inches (850 mm) in diameter and 19.68 inches (500 mm) high.

The Integrex i-400ST is a multitasking center that employs two turning spindles, a milling spindle and lower turret, so that manufacturers can process first and second operations simultaneously or perform required sequential operations on a single workpiece. The machine’s main horizontal turning spindle with a 12-inch chuck is capable of C-axis indexing in 0.0001-degree increments. The main turning spindle is a 40-hp (30-kW) integral spindle motor that provides a 3,300-rpm maximum spindle speed, while the second, opposed headstock with a 10-inch chuck features a 35-hp (26-kW) integral spindle motor and 4,000-rpm top speed.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

Large Part Machining

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)