Micro-Part Collets Make Subspindles Sing

A proprietary grinding process and the application of clamping force exactly where it’s needed ensure secure, concentric gripping with a collet system that can potentially fit every turning machine in a shop.

There’s good reason why subspindle-equipped turning centers, particularly Swiss-type lathes, are so popular for small, complex parts produced in high volumes. However, there’s also good reason for the prefix “sub.” Automatic part hand-off for backworking operations isn’t viable without secure gripping, and the smaller, already-machined portion of the work presented to the subspindle tends to create more challenges than the raw barstock gripped in the main spindle. As a result, subspindles can be limited when it comes to blind-hole broaching, heavy peck drilling and other processes that risk pushing a part off-kilter or damaging it.

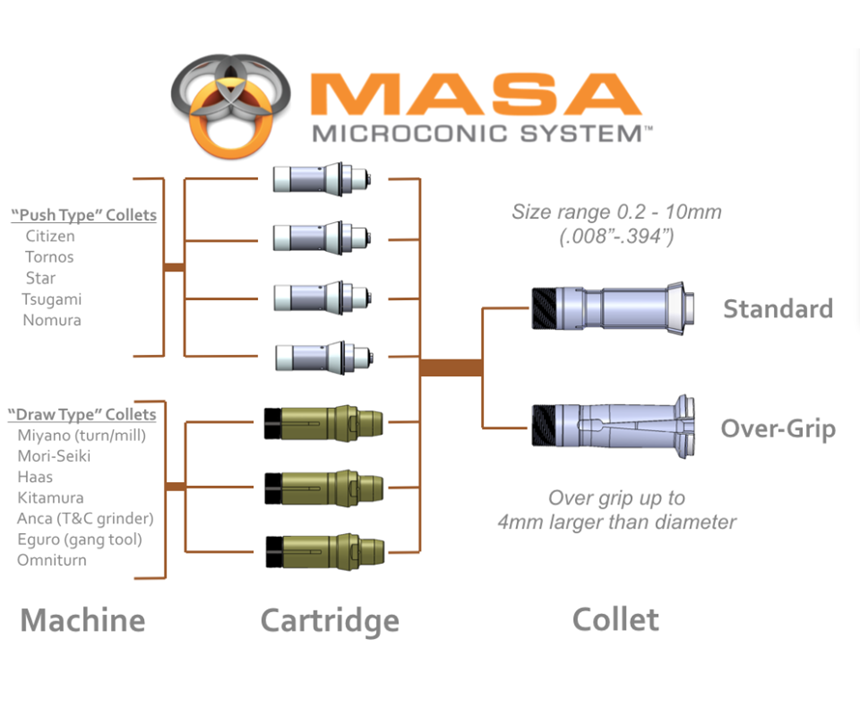

However, the right workholding can break down these barriers, says Matt Saccomanno, CEO of Masa Tool (Oceanside, California). Founded in the wake of Mr. Saccomanno’s own frustration with secondary operations and underutilization of subpsindles, Masa Tool offers the Microconic system, an alternative to traditional, extended-nose collet designs that applies force closer to the part for greater rigidity and concentricity—advantages that extend to main-spindle operations as well. Another benefit is the ability to adjust clamping pressure at the spindle nose to grip securely without damaging small, fragile workpieces. On the efficiency front, a collet in one size can be swapped for another without reaching anywhere beyond the spindle nose, and any collet can fit multiple draw-type or push-type machine collet closers. This saves time and eliminates the need for different collet series for different machines. Finally, overgrip models that expand 0.157 inch (4 mm) beyond the clamping diameter enable reaching over and gripping the part behind large-diameter areas.

The Microconic system consists of two primary components: a cartridge that fits in the machine’s standard 5C, TF20 or TF25 collet closer, and the Microconic collet itself, which fits into the cartridge. Collets accommodate workpiece diameters ranging from 0.008 inch (0.2 mm) to 0.394 inch (10 mm). Total indicator runout (TIR) is guaranteed at 0.0002 inch (5 microns) at the workpiece, absent any runout introduced by the machine structure or other elements of the setup, Mr. Saccomanno says. He adds that the cartridge can be used as a precision gage to calibrate spindle accuracy.

Installation is simple. Users place the machine in a safe state for collet changing; insert the appropriate Microconic cartridge; and thread the Microconic collet into the cartridge. “You put it in your spindle and leave it there,” Mr. Saccomanno says about the three cartridge models, each of which can accept any standard or over-grip collet. This capability enables switching to a different-diameter collet for a different-diameter part and setting the correct chucking force in roughly 2 minutes, compared to the 15 minutes it might take to swap, say, a TF25 collet, he says.

There’s no “feel” involved in tightening the collet, he says. That’s a task accomplished with the company’s Micrograd wrench, which features micrometer graduations of 0.001 inch (0.02 mm) to aid users in dialing in the perfect closure on either a workpiece or a gage pin of the same size. This configuration relegates the machine’s own clamping mechanism to the role of an actuator that triggers the opening or closing of the collet. As such, he advises keeping the machine’s own function at a medium force setting and allowing the Microconic cartridge to control the actual chucking force. Machined from a single piece of hardened steel, the cartridge preserves the dead-length operation of “push-type” collet systems (that is, the collet itself doesn’t move in or out as the machine cartridge actuates the chuck).

In addition to better facilitating secure clamping without damaging thin-walled or otherwise delicate workpieces, self-contained, dial-micrometer force adjustment helps ensure setups aren’t affected by temperature fluctuations that might subtly alter the machine structure between collet-closer and collet. As Mr. Saccomanno puts it, “From the first part in the morning to the last part on second shift, it grips the same. You don’t have to play with it throughout the day.”

He credits much of that precision to the fact that clamping force is applied directly over the workpiece, a contrast with traditional extended-nose designs that apply force farther back. He also credits the manufacturing process. Tapering collet jaws to interface with the machine is nothing unusual. However, Masa Tool employs a proprietary, five-step grinding process that leaves each jaw with a particularly precise conical shape (hence the name “Microconic”) that forms a particularly tight fit. More specifically, a “slight crown” ensures that the contact point is always centered, he explains, citing the pattern of wear marks on well-used collets as evidence. “Traditionally, you’ll see wear closer to the slots rather than in the center, between the slots,” he says. “There’s no uncertainty about whether (a Microconic collet) will touch on the left or the right side first. That’s where you’ll get some variation in traditional designs.”

Gripping wasn’t the company’s only focus when designing the Micronic system. Reliable part ejection is also critical, Mr. Saccomanno says, particularly with overgrip collets that offer such a wide gripping range. That’s why overgrip models ship with a Microject, a brass ejection guide sleeve that can be machined to mirror the outer profile of the workpiece. Once threaded into the over-grip collet, the sleeve prevents parts from falling inside the chuck or getting stuck rather than ejecting into the parts catcher. The sleeve also provides a tight seal that improves the ability of through-spindle coolant or shop air to aid in part ejection.

Granted, Mr. Saccomanno recommends using programmed cycle stops while validating a production setup to ensure part ejection is reliable. Nonetheless, combined with the precision and gripping security common to all Microconic collets, capability for extreme overgripping can enable “doing things on the subspindle that you never would have dreamed of before,” he says.

Related Content

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreMoving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

Read MoreSimple Workholding for Robotic Automation

Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)