Precision Workholding Keeps Quality High for Gun Manufacturer

Keeping up with the latest and best processes is important for any shop, even one that produces a product that has been manufactured since the Industrial Revolution.

Edited by Lori Beckman

Keeping up with the latest and best processes is important for any shop, even one that produces a product that has been manufactured since the Industrial Revolution. CMMG (Fayette, Missouri), a faith-based manufacturer of AR-15 rifles, 22LR AR-15 conversion kits, and accessories, recently implemented a new high precision workholding system to stay on top of part quality and improve production capability.

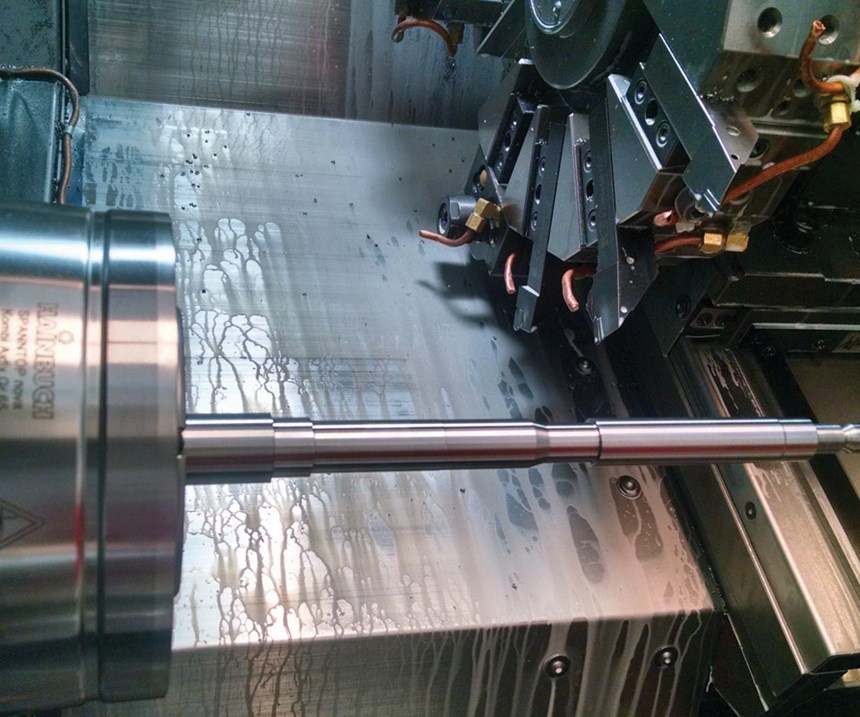

CMMG’s line handles nine different calibers of ammunition in multiple barrel variations from 4.5 to 24 inches in length, using 416 stainless and 4140 stainless chrome moly.

Featured Content

“We were having workholding problems due to loss of rigidity on the CNC lathes used to turn our barrels. Speeds, feeds and depths of cut were well below optimal,” says Timothy Crabtree, CNC machinery manager at CMMG. “Also, we were having issues with inconsistency in clamping pressure, which was causing chatter problems. These difficulties were especially acute because of tolerances with concentricity, and our production demands are rapidly increasing.”

Originally based on the M16 military rifle, the AR-15 that CMMG manufactures has morphed into multiple configurations and is popular among hunters, marksmen and law enforcement, and is used in defense applications around the globe. In the 12 years since it was founded, CMMG has expanded its product lines, from the Mk47 K, 7.62 × 39-mm SBN pistol to the Mk4 V2, 5.56-mm rifle. It has also added to its full line of parts and ancillary equipment such as magazines, stock kits, muzzle devices and upper and lower receiver parts. To attest its reputation, the company recently received the NRA Golden Bullseye Award, when its Mk47 Mutant was recognized as the Tactical Gun of the Year.

To uphold its name, CMMG knew that its workholding needed to be more than sufficient. Realizing that a high precision system would provide both increased quality and more versatile production capability, the staff evaluated several sources and decided to partner with Hainbuch America Corp. Hainbuch manufactures a variety of workholding systems to accommodate turned parts of various size ranges.

“What initially impressed us with Hainbuch was the engineers’ response,” Mr. Crabtree says. “More than any of its competitors, the company evaluated our needs and worked to ensure that the system it proposed would be the right one, both now and in the future.”

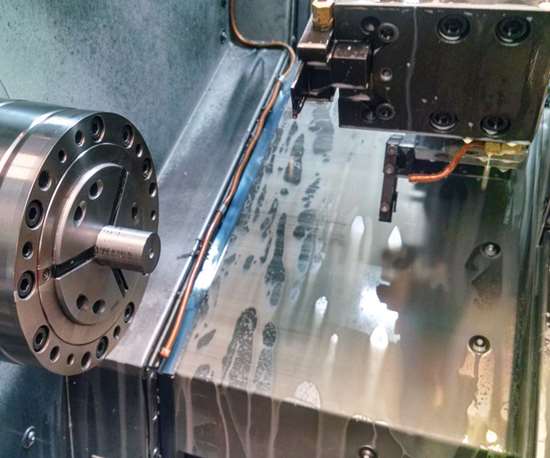

Hainbuch recommended the Spanntop Nova Combi dead length model in the 65-mm size range. The model’s chuck and clamping head is designed to permit the barstock that will become the barrel to be fed through the center. When it engages the end-stop, the unit exerts the proper amount of pressure to ensure stability throughout the machining operation.

“The only challenge that we faced at CMMG involved the correct conversion of hydraulic pressure on the lathe to collet pressure on the chuck, which was quickly solved by our technical support because clamping force over the length of the barrel was the main issue,” says Tom Buraczewski, Hainbuch regional sales manager.

The new workholding equipment includes gripping, extracting and clamping. The collet provides sufficient rigidity to eliminate chatter. The collet chuck and clamping head met the precision standard, even on CMMG’s older lathe.

“The Hainbuch collet system allowed us to use the correct cutting inserts and run at or above optimal conditions,” Mr. Crabtree says.

For instance, the shop went from 0.032 to 0.070-inch depth of cut. Feet per revolution improved from 0.015 to 0.018, and surface feet per minute increased from 820 to 925—the maximum spindle RPM. On another part, it went from 0.030 depth of cut to 0.050; feet per revolution went from 0.015 to 0.017; and surface feet per minute from 800 to 925. Pulling length deviation (same part, three pulls) has gone from 0.010 to 0.001 inch. Cutting tool life has been extended, and the company continues to discover new improvements.

“Evaluating the system at CMMG, we understood that the variety of barrel sizes posed a problem when it came to changing setups,” Mr. Buraczewski says. Therefore, to ensure precision throughout the system, Hainbuch engineers designed a special end-stop that guarantees length accuracy and improves production.

Mr. Crabtree points to the end-stop that the engineers created as an example of how dedicated partners provide a level of support that sets them apart from the competition. “Our friends at Hainbuch lived up to our corporate motto,” he says. “Like ours, theirs is a business ‘where mundane details are never forgotten.’ We estimate that our barrels are good for up to 10,000 shots. Working together, we can be sure that our customers get every one.”

For more information from CMMG, visit cmmginc.com or call 660-248-2293.

RELATED CONTENT

-

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.

-

Cutting Tool Coating Production

This article looks at the coating methods available for carbide cutting tools.

-

5 Process Security Tips for Parting Off

Here are five rules of thumb from Scott Lewis, a product and application specialist at Sandvik Coromant, to optimize the parting off process, and as a result, maximize tool and insert life.