Reasons for In-Sourcing Machining

Companies illustrate various reasons why they have brought or kept machining in-house instead of outsourcing it to a supplier.

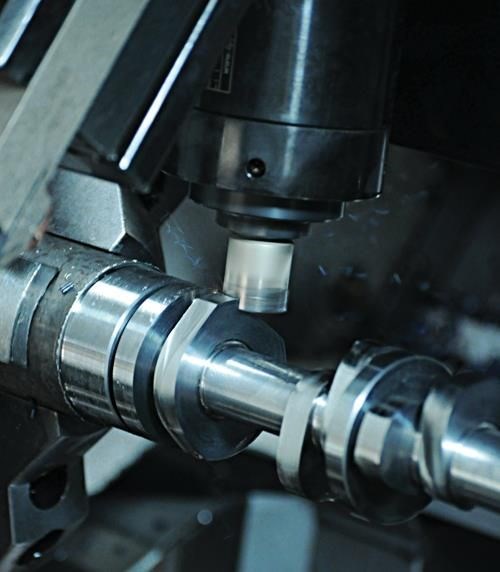

Having twin-spindle/twin turret lathe technology in-house lets Comp Cams produce billet racing camshafts more quickly than when it outsourced camshaft machining.

Effort Foundry used to send castings away for machining, but the company recently invested to create a new, in-house CNC machine shop. Quality control was a big part of the reason for taking ownership of this operation. See the link below for more detail.

This is just one of the potential benefits of retaining control of machining. The reasons why companies have brought or kept machining in-house includes all of the following:

- Quality control. Example: Effort Foundry.

- Potential to scale up for increasing demand. Example: Ergoseal.

- Manufacturing efficiency that comes from knowing the product very well. Example: Reid Machine.

- Inventory control. Example: E.F. Bavis.

- Fast introduction of new designs. Example: Comp Cams.

Of course, to bring machining in-house, a company needs staff to do the machining. Finding the strategy to develop this staff might be the reason machining returns. PEP Lacey is an example of this.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)