Published

The Softer Side of Machine Tool Builders

These low-cost VMCs come standard with a number of software features that enable them to compensate for machining’s inherent physical and thermal challenges.

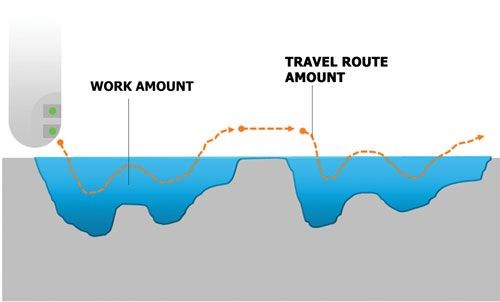

A standard tool load detection function regulates the feed rate override to maintain constant spindle power while cutting irregularly shaped workpieces.

Mention a machine tool builder, and thoughts first tend to drift toward mechanical stuff—ways, spindles, tables, etc. However, software can be a big part of how effective a machine tool operates on the shop floor. Consider Hwacheon. The Korean machine tool builder has developed a selection of standard software functions for its new, low-cost Vesta VMC line that compensates for things like centrifugal force, thermal expansion and variances in tool load that can adversely affect machining accuracy.

Learn more about that software in this article.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)