How Much Production Run Documentation Do You Provide?

Any time you wonder why a CNC operator doesn’t know something that you think is obvious can be taken as a signal that you are not providing enough production run documentation.

Most companies are pretty good at providing sufficient documentation to the people who get CNC machines ready to run production. At the very least, most provide a one-page setup sheet that shows the most critical information—the workholding device to use, where it is mounted on the table and a list of cutting tools and the tool stations into which they are loaded.

Some companies provide more information, including a complete list of tooling components and photographs depicting how the setup was made in the past. Anything that takes away guesswork should be included in setup documentation. The decision regarding how much setup documentation to provide should be based upon the skill level of the least experienced setup people. While it seems obvious that setup people must be given enough information to successfully make setups, many companies provide very little production run documentation for less experienced CNC operators.

Some companies simply expect the setup person to relate what must be done. This may be acceptable for experienced operators or if only one operator is involved. However, with lower skill levels, or if the company has more than one operator working on a machine during multiple shifts, it’s likely that some operators will struggle during production runs.

As with setup documentation, production run documentation should take the guesswork out of running CNC machines. Excessive questions, duplication of effort, mistakes, scrap workpieces and wasted time are symptoms of poor production run documentation. Any time you wonder why a CNC operator doesn’t know something that you think is obvious can be taken as a signal that you are not providing enough production run documentation.

• Workpiece loading instructions—If the same workholding devices are used regularly, such as hydraulic chucks on turning centers and table vises on machining centers, the task of workpiece loading may be pretty simple. There may not be much to explain in documentation. However, with more complicated workholding devices, there may be special workpiece loading considerations. For example, if a complex fixture is used on a machining center, the order by which clamps are tightened on the workpiece may have an impact on how well the workpiece is held and located, or certain workpieces may deform if clamped too tightly. Indeed, incorrect or insufficient workpiece loading can have serious consequences. Any special considerations should be explained in production run documentation.

• Special tasks during the cycle—While most companies strive to minimize or eliminate operator intervention during the CNC cycle, there are still times when companies expect CNC operators to do something on the machine during the cycle. These tasks can include clearing chips from pockets in the workpiece, applying tapping compound prior to tapping and loosening clamps for finishing operations. If your operators are expected to perform such tasks, you must ensure that operators know what it is they are supposed to do when the machine stops. A message in the program near the program stop command can help, but instructions in the production run documentation can clarify further.

• Sizing adjustments during the production run—Most operators are expected to measure workpieces and make sizing adjustments to keep machined surfaces within their tolerance bands. To do this, the operator must know which cutting tool is related to the surface being sized. They must also determine the offset number related to the cutting tool. Most companies are pretty consistent, keeping the offset number the same as the tool station number, but it can still be pretty difficult for anyone other than the programmer to determine which tool station number is related to the tool. At the very least, it can be time-consuming. By one means or another, production run documentation should marry machined surfaces to size-controlling offset numbers, clarifying for the operator which offset must be adjusted to hold size on each machined surface. One way to do so is to color-code a workpiece drawing, marking each machined surface with a color that corresponds to an offset number. The operator will know at a glance which offset must be adjusted for each machined

surface.

• Dull tool replacement—Most companies also expect their operators to replace dull tools during the production run. The physical tasks related to replacing dull tools are identical to those required during the initial setup of the job. As with all production run tasks, anything you can do in production run documentation to help will simplify things for the operator. For example, in many companies operators are expected to determine when tools are getting dull, requiring each operator to judge when he or she feels that a tool must be replaced. This can lead to inconsistencies among operators—such as the tendency to replace all inserts at the beginning of each shift. If possible, production run documentation should specify approximately how long critical cutting tools will last.

• Quality control and other tasks during the production run—If you expect your operators to do anything else during a production run, production run documentation should explain these tasks, as well. Cleaning and deburring workpieces, for example, are commonly the responsibilities of the CNC operator. Many companies also expect operators to measure workpieces and report findings to the company’s statistical process control (SPC) system. Again, anything that clarifies what you expect operators to do should be documented.

Related Content

Understanding G27, G28, G29 and G30

Take a closer look at these reference position commands.

Read More8 Ways to Increase Productivity on the Manufacturing Floor

When it comes to machine shop productivity, continuous improvement depends on efficient employees, equipment and processes.

Read More10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read MoreHow to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

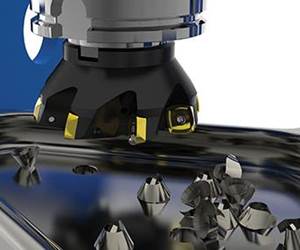

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)