Technical Talent: The Pipeline For A Critical Resource

As our economy has evolved from agrarian to industrial to information based, the importance of math and science has increased. The first cotton gin was emblematic of advances that symbolized growing reliance on technology and productivity solutions that decrease the need for labor and increase reliance on skill and capital.

As our economy has evolved from agrarian to industrial to information based, the importance of math and science has increased. The first cotton gin was emblematic of advances that symbolized growing reliance on technology and productivity solutions that decrease the need for labor and increase reliance on skill and capital. Economic evolution lifts individuals and industries that recognize a rising trend and crushes those who cling to the wrong side of an industry cycle.

Throughout the 20th century and into the 21st, the United States has enjoyed a world-leading position as having the economy with the highest per capita output and productivity of any G7 nation. Educating our workforce initially drove this productivity.

More recently, growth has depended on technological advancements, fueled by innovation and a capitalistic structure offering incentives that surpass any other form of financial and social interaction. The foundation of innovation is composed of science, math, creativity and the ability to identify and satisfy customer needs. This is especially true as we move further into the information-based economy, where the skill and technology components of the total productivity equation become more important than general labor and capital.

In the job market, a growing divide between the most and least educated U.S. workers has persisted for at least three decades and shows no sign of abating. The increasing spread between the wages of the lowest skilled workers and the highest is indicative of an ever-present and more heavily weighted knowledge and skill premium. A greater demand for skilled workers is driving higher wages for this category. The need for more information-based workers will likely drive the premium even higher.

There appears to be a corporate analog to the wage divide in the form of rewards for industries and firms that compete based on the essential elements just described and penalties for those that do not. Key corporate valuation attributes, value (earnings relative to market price) and growth (estimated potential for consistent earnings increases over time) are ultimately driven by the firm's development and use of its knowledge base relative to competitive forces.

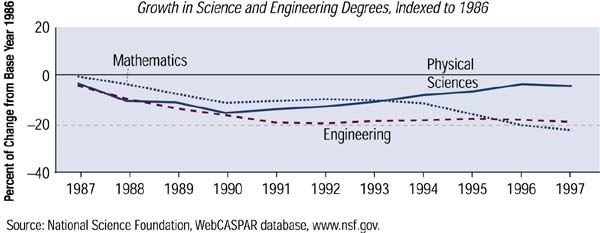

For the last couple of decades, the number of students studying math and engineering has steadily declined. And, we are on the cusp of what may be a huge exodus of Baby Boomers from the job market.

Around 2008, there will be another peak of college enrollment (the last one was in 1985). Industry needs to encourage students to pursue fields of study in math and science to ensure sufficient long-term access to qualified technical talent. Market forces will ultimately pull in more talent, but it will be at an even higher wage premium.

There are several ways you can help.

1) Find out what resources and information your firm can contribute to your local secondary schools and community colleges.

2) Ensure that your local schools have sufficient computer resources to expose all children to computing environments.

3) Encourage local students and educators to attend IMTS in Chicago in September (either in person or virtually at www.IMTS.com). Many attending companies will have show content designed for potential technical students.

Active participation now can help ensure sufficient levels of skilled talent in the future.

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=860)

.png;maxWidth=300;quality=90)