The Need for Speed

In high-volume production, cost-effective gaging depends on how fast you make measurements and interpret the results. Here’s one approach that might meet the needs of your operation.

In a high-volume production environment, the cost of gaging is related to the speed with which measurements can be made and how fast results can be interpreted. Let’s look at one example, compare several approaches and see which one may be the most productive.

A common task in manufacturing engine blocks is measuring the diameters of crank, cam and counter-balance bores. These are a bit unusual in that they tend to have tight tolerances and interrupted surfaces, and, depending on the size of the block, they can be fairly deep.

We’ll use air gaging for our comparison, as it has always been a popular and successful way to make these engine block diameter checks. Air gaging has many advantages for inspection tasks. It is quick and easy to use, requiring little skill on the part of the operator. It is highly adaptable to measuring these special features for dimensional tolerances. And as a non-contact form of measurement (in the sense that there are no hard contacts), air gaging is useful for measuring the bores even though there might be slight traces of dirt or coolant on them because the air pressure will tend to clear away such debris.

Let’s start at the most basic air plug and work our way up the productivity ladder.

A cam bore consists of a number of identical bores spaced through an engine block with large gaps in between. Often the bores are not only measured for diameter, but are also explored for “out of roundness” by taking two diameter checks 90 degrees apart from each other.

The simplest air gage check could be a standard two-jet, single-circuit air plug on a long handle that would enable it to be passed from bore to bore. This seems pretty reasonable and would do a perfectly fine job on the diameter check. But from the operator’s point of view, it may not be the fastest or most easy to use. While air plugs tend to have lead-in angles built into the front of the plug to enable easier entry into the bore, the operator still has to make the effort to align the plug to the bore. This is fine when the bore is in front of the operator, but if the bore is buried 18 inches deep in the body of a block, it’s not so simple. So in the end, the operator’s routine is to: align plug to bore, measure one diameter, rotate the plug 90 degrees, measure the second diameter, then repeat four more times. A pretty slow process, but in terms of the air plug, it is the least costly method.

An air plug modification that can make the task easier and faster is to lengthen the body of the air plug so that it spans two bores simultaneously but still measures the one diameter. With this type of plug, the operator has only one alignment to do, and from then on, the plug is aligned for all bores. The process is: measure one bore, rotate, measure and push through without the need to realign. This saves valuable seconds in a critical manufacturing process when speed is important.

One of the great things about air tooling is its ability to include multiple jets on a single plug, allowing multiple diameters to be measured at once. The next logical step up in productivity would be to measure two diameters at the same time, but opposed at 90 degrees to each other. With a display system that shows both diameters simultaneously, the operator would simply enter the first bore, position it to the correct depth and read both values. This would be repeated four times, in effect cutting the measuring time in half.

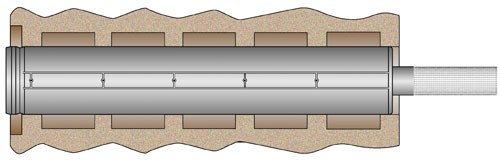

But there is one more modification to check the bores more efficiently. This enables you to do it all at the same time in one measurement shot. This involves making a special air plug with five levels of two air circuits at each diameter. This is an easy task for air tooling, but on the instrumentation side, the air-to-electronic convertors are a bit pricey. Yet in terms of efficiency and ease of use by the operator, nothing is easier. The 10-circuit plug inserts into the bore, all diameters and runout conditions are measured simultaneously, and the operator gets an instant pass or fail indication on the part.

So which method best meets the needs of your operation? Certainly the most complex—and expensive—solution is going to be the most efficient. But is it also likely to be the most

cost effective? Taking a measuring cycle from 60 seconds down to less than 10 is a significant savings in terms of cost and ease of use by the operator. Whether that is a plus for you depends on how you define “high volume production.”

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)