Five-Axis Machine Produces Medical Parts without Wasted Capabilities

.decimal Inc. needed to efficiently manufacture medical devices. Mazak's VCU 400A 5X machines met the company's need to precisely and reliably make devices quickly.

When machining unique medical devices used to administer radiation treatments for cancer patients, high quality and fast turnaround is of utmost importance. Luckily, Sanford, Florida-based .(dot)decimal has found a way to achieve both. The shop conducts all its business on a completely digital, automated, internet basis, enabling it to receive job orders before 12 p.m., process them on a variety of machine tools from Mazak Corp. (Florence, Kentucky), and ship them complete by 6 p.m. that same day.

.decimal produces mostly filters/apertures that regulate the width and depth of radiation treatment beams. The devices are used for treatments involving proton (very precise), photon (blurry) or electron (low-mass) beams, depending on the tumor type and location. These different beam characteristics dictate filter requirements in terms of part specifications and feature geometries.

According to CEO and President Richard Sweat, each device is as unique as a snowflake. For the 100 to 200 patient-specific jobs shipped per day, the shop has no clue what part geometries it will have to machine until the orders are received from hospitals and research facilities.

The process begins when doctors/facilities load CT scans and MRI results into a special software and build a 3D virtual model of the patient to map out the tumor. Then, they use the company’s custom software called planning.decimal (p.d) to help design, visualize and order the needed devices. The software uploads the necessary digital files and sends them via the internet to be manufactured.

Once at the shop, the company’s in-house-developed manufacturing automation software, automate.decimal (a.d), controls all its processes, automates workflow and generates the tool paths. It also controls communication with the Mazaks and manages their functions to ensure effective machine utilization and part quality. The software is a vital link between device/aperture specifications and the machine tool programming language.

At the heart of the shop’s part-production operations is what Mr. Sweat calls a “farm” of 26 Mazak machines, the bulk of which are Vertical Center Nexus (VCN) vertical machining centers along with an Integrex 200S multitasking machine. The company recently added two full five-axis Vertical Center Universal (VCU) 400A 5X VMCs to efficiently process apertures used in a new type of proton-radiation-beam therapy.

Customer orders populate the company’s servers with incoming orders throughout the day, and the software tracks each patient’s device through manufacturing, invoicing and shipping. It determines which machines are open and allocates job files accordingly. The software also displays real-time job status, tracks part material back to the foundry and tracks who machined it on which Mazak. It also shows current machine status. According to Kevin Erhart, chief technical officer, many of these steps are critically important to maintaining the levels of traceability required by the Food and Drug Administration.

“The extreme stability of our processes results from the elimination of variation,” Mr. Erhart explains. “That is why we have all Mazaks. They not only provide reliable and consistent high performance, but also fast and precise machining.”

After the software sends a tool path to the shop floor, machinists load raw parts into the designated Mazaks, each of which is dedicated to run only one specific type of material, mainly for recycling purposes. Once completed, parts move on to cleaning, inspection and finally shipping.

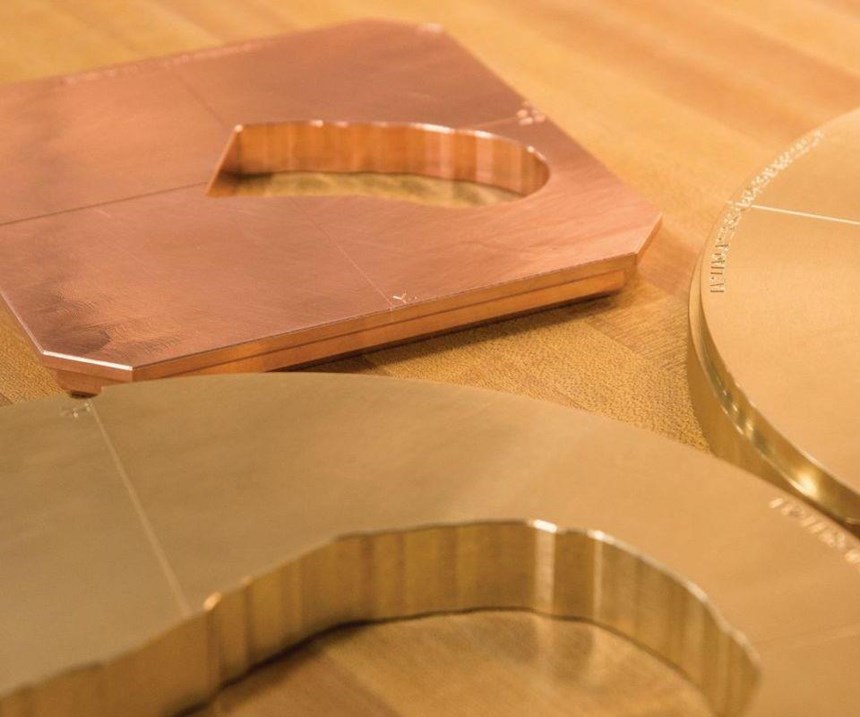

Aperture/filter tolerances are typically ±0.010 inch; however, the shop actually machines to much tighter tolerances because the Mazaks enable parts to be produced well within Six Sigma requirements, Mr. Sweat says. The apertures/filters are made from brass, acrylics, copper, aluminum and wax, with brass and copper filters used most often for apertures that restrict the lateral shape of the beam and keep it from spreading beyond the tumor area. The aperture patterns are a stencil or profile of a tumor’s periphery and are machined completely through the part.

Devices known as range and tissue compensators require variable-depth pockets/closed cavities to be machined out. Their varying depths are what regulate the intensity or penetration depth of the radiation beam. Thicker portions of the cavity will block or limit the beam, while the thinner areas allow more of it to pass through to the patient.

Variable-angle-beam, divergent-corrected-type apertures spurred the company’s latest venture into full five-axis machining. Used for a relatively new proton-radiation-beam therapy, these devices are similar to standard apertures in that they require machined cavities. However, the cavity contours in these apertures include variable-angle walls. These angles further pinpoint the proton beam to provide a better beam resolution to spare nearby healthy tissues from receiving high doses of radiation.

Initially, .decimal machined the new apertures using a Mazak Integrex-type multitasking machine with second turning spindle and milling spindle. However, that machine provided much more capability than was needed for the particular job, Mr. Sweat says. What he wanted was high performance, but at a more cost-effective price. That was when he discovered Mazak’s VCU 400A 5X full five-axis machine.

“It’s all about matching the angles of the proton-beam divergence since the physics of radiation blocking and scattering make these angles a highly critical feature of the design,” Mr. Sweat explains. “Our two Mazak five-axis VCUs enable us to machine these angles more accurately than using our existing bolt-on rotary-table-type machines and much more cost effectively than using the Integrex machines. Our processes demand quality, stability, reliability, affordability and consistency. The VCUs give us all that, and they have operated flawlessly since we added them.”

The VCUs machine only the proton-beam-aperture parts. For precise five-axis machining, the machines’ trunnion-style rotary/tilt tables are constructed with durable high-speed roller gear cam drive technology for high

torsional rigidity and positioning accuracy. The tables tilt +95 degrees/-45 degrees in the B axis and rotate 360 degrees in the C axis, and they can accommodate workpieces weighing as much as 440 pounds.

While it is a small footprint machining center, the VCU provides .decimal with travels measuring 19.88 by 15.74 by 17.12 inches (505 by 400 by 435 mm) in the X, Y and Z axes, respectively. A high-speed rapid traverse rate of 945 ipm (24 meters per minute) in the machine’s three linear axes help reduce the shop’s non-cut times.

Aperture part cycle times at the shop typically fall between 10 and 20 minutes, and compensator/filter devices can range from 30 minutes to several hours, depending on part size and surface complexity. While the shop tries to optimize cycle times whenever possible, there is a point of diminishing return in which the cost of wear and tear to the machines outweighs the benefits of seeking shorter machining time.

“For us, we’d rather run parts at a reasonably fast speed while also getting the most life out of our machine ballscrews and spindles,” Mr. Sweat says. “We are process maniacs, and key to controlling our processes is having consistency and repeatability in our machine tools. We want stable machines for stable production together with maximum tool and machine lives.”

Business continues to grow for .decimal, and the shop plans to increase its international deployment. Mr. Sweat says that being digitally automated with the in-house-developed software enables the shop to make any internet-accessible machine tool part of its farm. He envisions several shops full of Mazaks in strategic countries, with the main Florida facility funneling the incoming jobs to them. All of which will help get much needed devices to cancer patients even faster.

Related Content

Five-Axis Turnkey Machine Halves Medical Shop’s Cycle Times

Horizontal five-axis machines cut cycle times in half at ARCH Medical Solutions – Newtown. But its leadership gives equal credit to a surprising factor: the OEM’s service department.

Read MoreArch Cutting Tools Acquires Custom Carbide Cutter Inc.

The acquisition adds Custom Carbide Cutter’s experience with specialty carbide micro tools and high-performance burrs to Arch Cutting Tool’s portfolio.

Read MoreModern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreYCM Alliance Hits IMTS

YCM Technology has joined with other like-minded machine tool manufacturers to take a solutions-based approach to manufacturing.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)