Workholding System Suits Five-Axis Machining by Clamping Underneath

The clearance is an added benefit of the quick-change system, potentially facilitating five-axis as an automation tool.

Five-axis machining has become one of the most important technologies in metalworking today. The reason is not because the technology is new (which, of course, it isn’t), but because it has gone mainstream. What used to be a niche capability for milling intricate contours is now a valuable automation tool in many shops, enabling not only those intricate forms, but also machining at many angles in one cycle to minimize the number of setups needed. However, the increased use of five-axis machining in general production means shops increasingly have to evaluate other components of their processes, such as workholding, with this capability in mind.

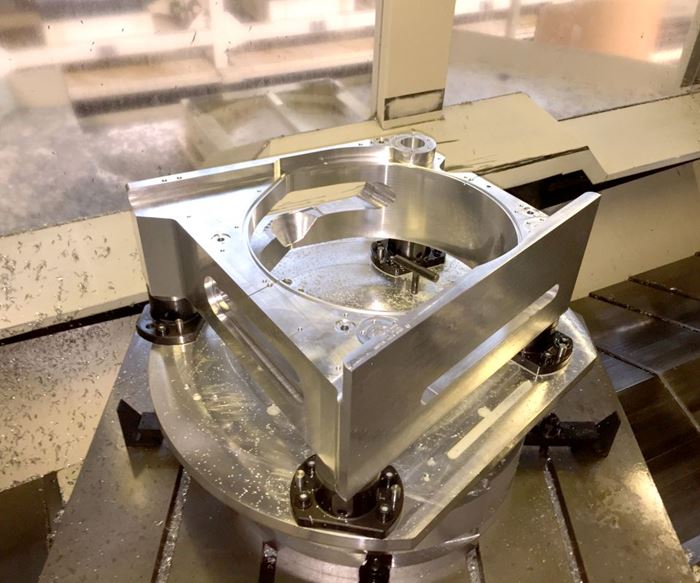

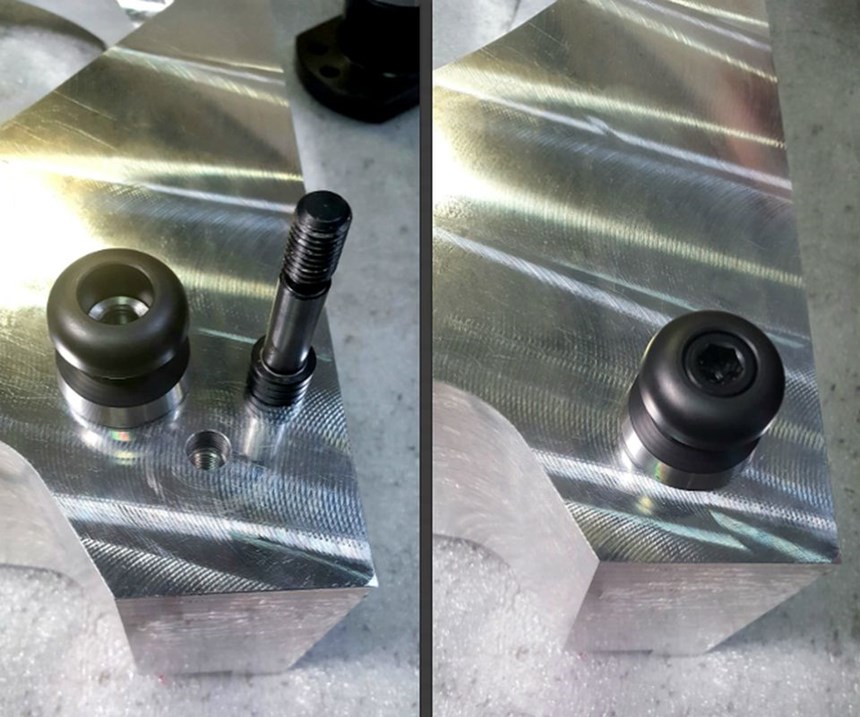

John Zaya, workholding product manager for Big Kaiser Precision Tooling, says that depending on the part, the right choice of workholding might be the key to realizing five-axis machining’s full promise for automated production. One of the options he often discusses in this context is the company’s “Unilock” system, which provides for repeatable, quick-change workholding using a receiver that clamps on a precision knob. Developed and long used for setup-time reduction, the system is now finding applications in five-axis machining not primarily because of the quick-change clamping, but instead because it offers a secure way to clamp the part entirely from underneath.

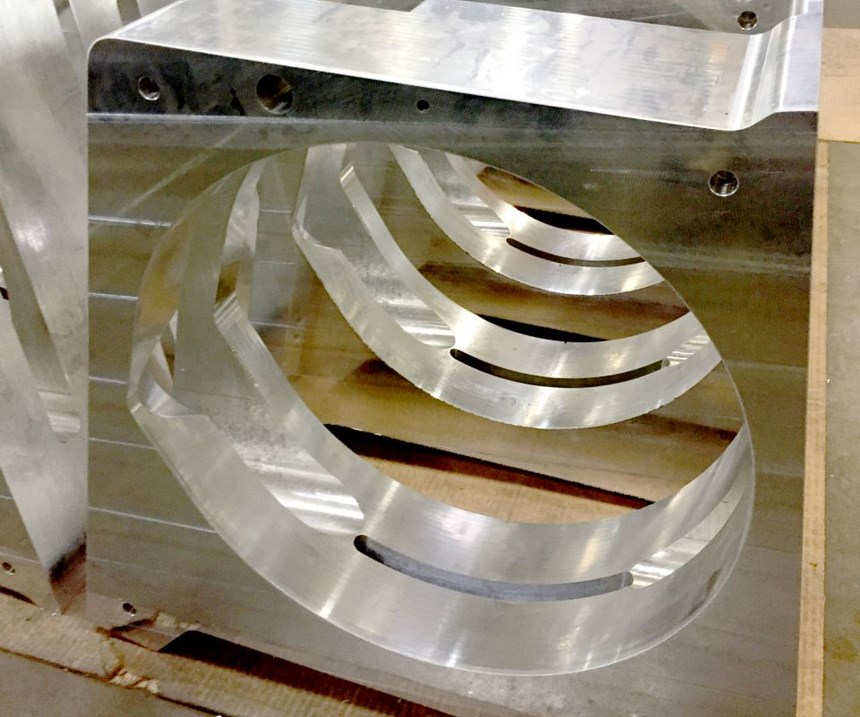

Access is an issue when clamping for five-axis machining, he says. A standard vise blocks the sides of the parts. A low-profile vise for five-axis machining leaves these sides more open, but grips only along the part’s lower edge. Even a custom fixture for a five-axis job is potentially problematic, he says, because of the danger of interference with the tool or spindle housing as the entire unit of part and fixture pivots throughout the workzone. However, the option to clamp exclusively on the underside of the part leaves the workholding essentially hidden—concealed from all these interferences by the workpiece itself. The system simply requires either preexisting holes in the part or the addition of holes for affixing the knobs used for this clamping.

In fact, the knob-and-receiver method of clamping makes the system modular, enabling posts to be built up for applications in which the underside of the part isn’t flat. (See example in the photos.) For its five-axis version, one concession the Unilock system makes is in its clamping mechanism, Mr. Zaya says. Pneumatic clamping is typical, but receivers used for five-axis machining feature mechanical clamping instead. This avoids any danger of air lines becoming tangled within the five-axis motion.

In this context, the system’s quick-change capability remains valuable, he notes. Because the five-axis machine is liable to be the most expensive in any given shop, it needs to be dedicated to the most valuable work. Using this workholding in conjunction with receivers on multiple machining centers can enable roughing to be performed on a lower-cost three-axis machine. The work is then removed from the three-axis machine’s set of receivers and quickly transferred and clamped into the five-axis machine’s receivers so that this machine can be used solely for the high-value precision-finishing work.

Related Content

-

When To Use A Collet Chuck

Don't assume the standard chuck is the right workholding for every lathe application.

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

-

IMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)